77

EN

Adjusting MINIMUM

– turn dial

t

to the minimum and leave dial

D

at the maximum

– the boiler will go to minimum operating conditions and the

display will show the message "

P00

" (indicating that it is

possible to adjust the minimum)

– press a button (

>

or

<

), the display will show a number

between 0 and 150

– press button

>

, to increase the value, or button

<

, to reduce

the value, until you see on the pressure gauge the pressure

value given in the table.

Once the required adjustment has been made, save it by

continually turning the dial

D

to the minimum value and

immediately afterwards to the maximum setpoint value.

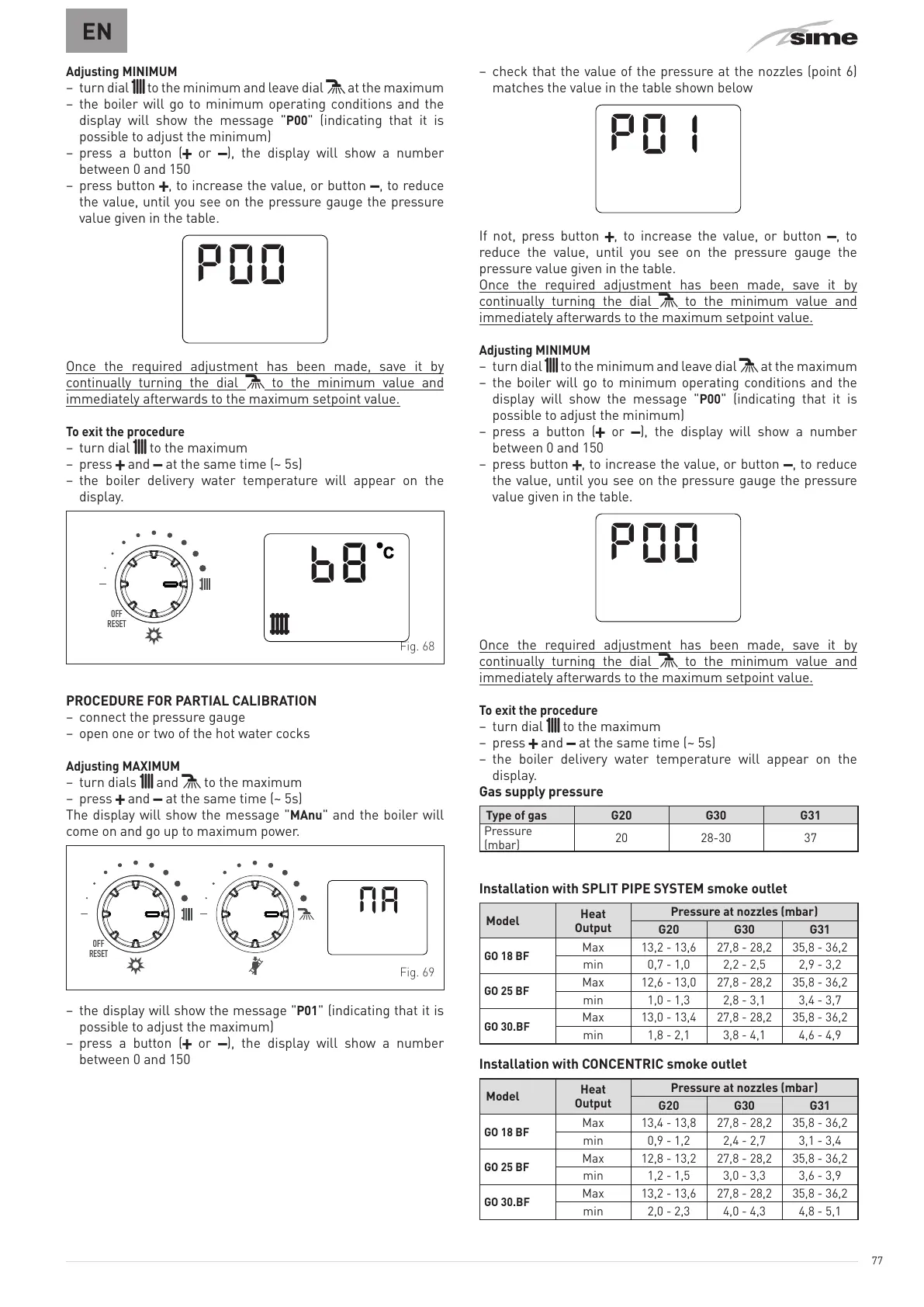

To exit the procedure

– turn dial

t

to the maximum

– press

>

and

<

at the same time (~ 5s)

– the boiler delivery water temperature will appear on the

display.

OFF

RESET

Fig. 68

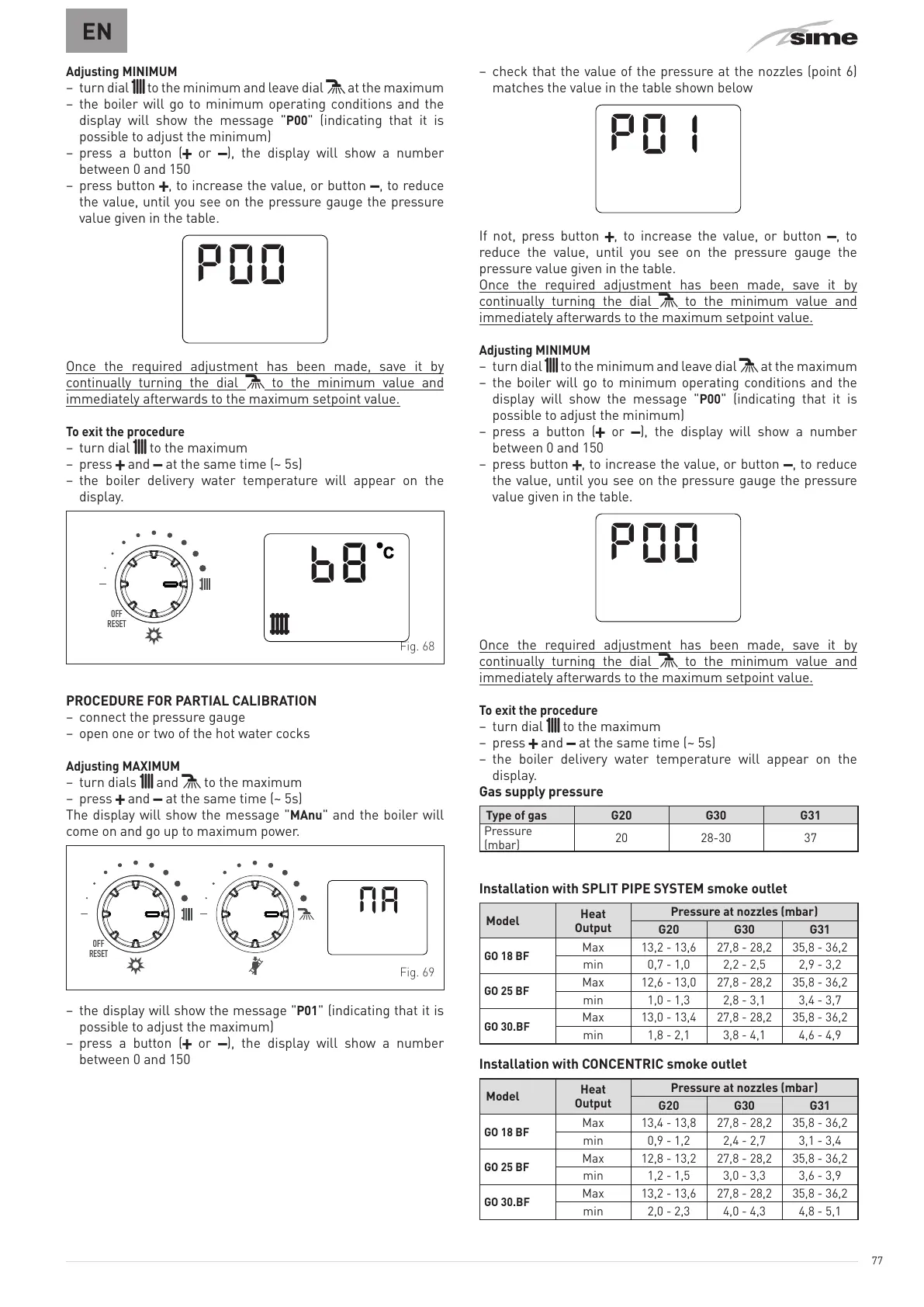

PROCEDURE FOR PARTIAL CALIBRATION

– connect the pressure gauge

– open one or two of the hot water cocks

Adjusting MAXIMUM

– turn dials

t

and

D

to the maximum

– press

>

and

<

at the same time (~ 5s)

The display will show the message "

MAnu

" and the boiler will

come on and go up to maximum power.

OFF

RESET

Fig. 69

– the display will show the message "

P01

" (indicating that it is

possible to adjust the maximum)

– press a button (

>

or

<

), the display will show a number

between 0 and 150

– check that the value of the pressure at the nozzles (point 6)

matches the value in the table shown below

If not, press button

>

, to increase the value, or button

<

, to

reduce the value, until you see on the pressure gauge the

pressure value given in the table.

Once the required adjustment has been made, save it by

continually turning the dial

D

to the minimum value and

immediately afterwards to the maximum setpoint value.

Adjusting MINIMUM

– turn dial

t

to the minimum and leave dial

D

at the maximum

– the boiler will go to minimum operating conditions and the

display will show the message "

P00

" (indicating that it is

possible to adjust the minimum)

– press a button (

>

or

<

), the display will show a number

between 0 and 150

– press button

>

, to increase the value, or button

<

, to reduce

the value, until you see on the pressure gauge the pressure

value given in the table.

Once the required adjustment has been made, save it by

continually turning the dial

D

to the minimum value and

immediately afterwards to the maximum setpoint value.

To exit the procedure

– turn dial

t

to the maximum

– press

>

and

<

at the same time (~ 5s)

– the boiler delivery water temperature will appear on the

display.

Gas supply pressure

Type of gas G20 G30 G31

Pressure

(mbar)

20 28-30 37

Installation with SPLIT PIPE SYSTEM smoke outlet

Model

Heat

Output

Pressure at nozzles (mbar)

G20 G30 G31

GO 18 BF

Max 13,2 - 13,6 27,8 - 28,2 35,8 - 36,2

min 0,7 - 1,0 2,2 - 2,5 2,9 - 3,2

GO 25 BF

Max 12,6 - 13,0 27,8 - 28,2 35,8 - 36,2

min 1,0 - 1,3 2,8 - 3,1 3,4 - 3,7

GO 30.BF

Max 13,0 - 13,4 27,8 - 28,2 35,8 - 36,2

min 1,8 - 2,1 3,8 - 4,1 4,6 - 4,9

Installation with CONCENTRIC smoke outlet

Model

Heat

Output

Pressure at nozzles (mbar)

G20 G30 G31

GO 18 BF

Max 13,4 - 13,8 27,8 - 28,2 35,8 - 36,2

min 0,9 - 1,2 2,4 - 2,7 3,1 - 3,4

GO 25 BF

Max 12,8 - 13,2 27,8 - 28,2 35,8 - 36,2

min 1,2 - 1,5 3,0 - 3,3 3,6 - 3,9

GO 30.BF

Max 13,2 - 13,6 27,8 - 28,2 35,8 - 36,2

min 2,0 - 2,3 4,0 - 4,3 4,8 - 5,1

Loading...

Loading...