4-11

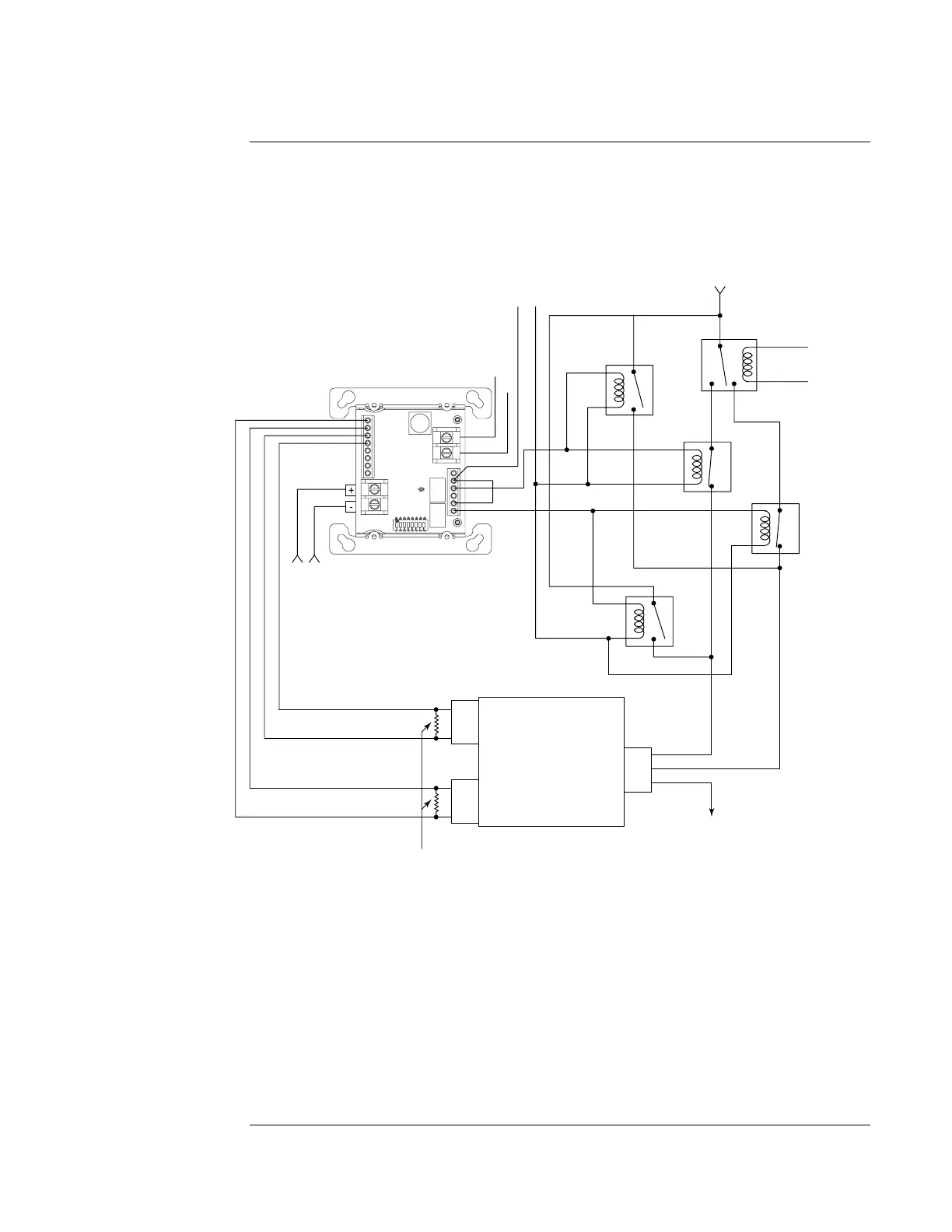

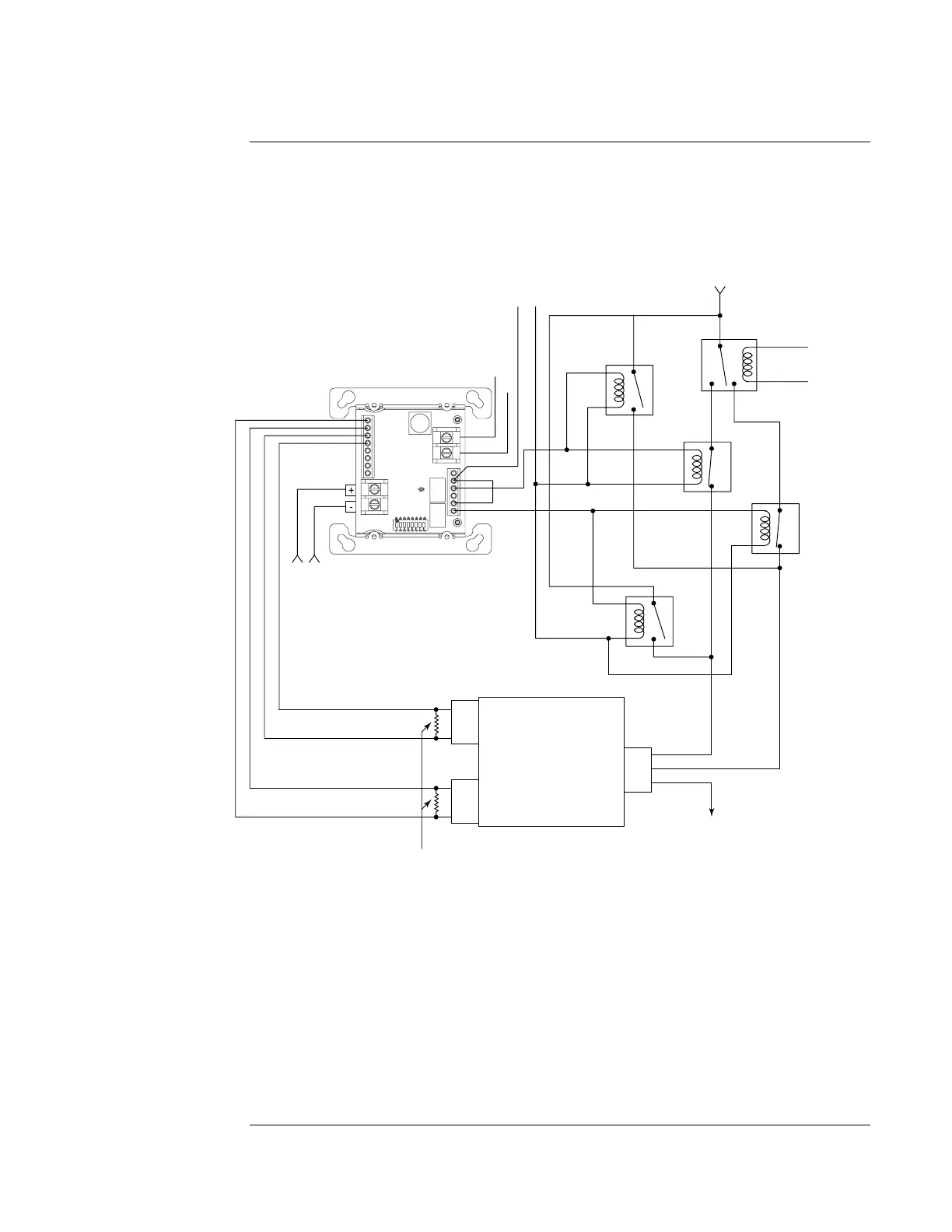

Feedback of the closure is accomplished using a 4090-9120 6-Point I/O Module to monitor the

closed position limit switch on the damper. The module also communicates with the Simplex

FACP via IDNet. Wiring from the module to the control relay is unsupervised, so it must be

mounted within three feet of the relay/damper in accordance with NFPA 72.

The figure below shows non-dedicated motorized damper control using the 6-Point I/O Module.

SMOKE DAMPER

LISTED

RELAY

(N/C)

LISTED

RELAY

(N/O)

(A)

(B)

LISTED

RELAY

(N/C)

DAMPER

CLOSED

POWER

RETURN

DAMPER

OPEN

POWER

N/O

MOTOR

COMM

CLOSED POSITION

LIMIT SWITCH

OPEN POSITION

COMM

COMM

N/O

N/O

INPUT 1

INPUT 2

LIMIT SWITCH

N/O

COMM

POWER

+24V

FROM

FACP

0V

SOURCE

LISTED

RELAY

(N/O)

EMS

6.8 K 1/2 W EOLR

(Per Installation Instructions, 574-876)

IDNet SLC

FROM FACP

1A @ 30 VDC

or

1/4 A @ 120 VAC

Figure 4-6. Non-Dedicated Motorized Damper Control

The two relay circuits of the 6-Point I/O Module are used, one to control opening the damper and

the other to control closing it. Relays [A] and [B] are activated to close the damper. One output

circuit controls Relay [A] to override the Energy Management System (EMS) and provide power

to the motor to close the damper. Relay [B] insures that no open power is provided to the motor

from the EMS. The other output circuit works in exactly the opposite fashion to control the

opening of the damper. The damper position is monitored by the two supervised inputs of the

6-Point I/O Module.

The wiring between the 6-Point I/O Module output circuits and the relays is unsupervised, so the

6-Point I/O Module must be mounted within three feet of the relays/dampers in accordance with

NFPA 72. The wiring to the limit switches is supervised, so no such restriction exists with the

monitor circuits.

Continued on next page

Non-Dedicated Smoke Control System Wiring Diagrams, Continued

Non-Dedicated

Damper Control

Loading...

Loading...