6. INSTALLATION

6.1 Lifting

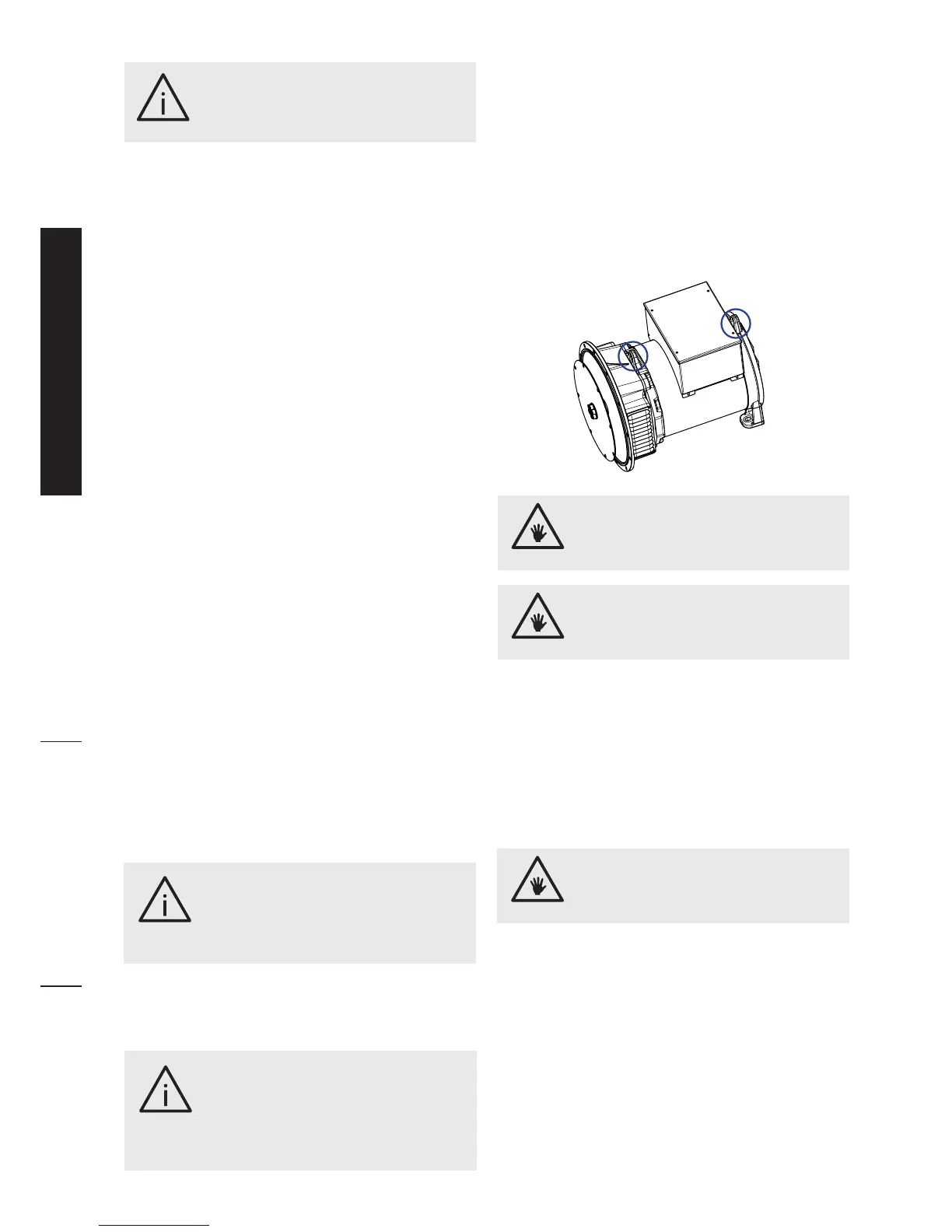

Liftandhandlethegeneratorwithsuitableequipment

eitheron a palletorby the liftinglugs locatedonthe

generatorinthepositionsindicatedinthefigure.

When lifting the HB generator use equipment with a

load bearing capacity of at least 200kg.

When lifting the IB generator use equipment with a

load bearing capacity of at least 300kg.

Whenliftingandhandlingsinglebearinggeneratorsthey

mustbekepthorizontalinordertoavoid,ifoperations

shouldgowrong,therotorfromslippingoutandbeing

damagedandpossiblycausingsevereinjury.

6.2 Mounting on engine

Fortighteningtorquesrefertosection6.2.3.

Formechanicalconnectionsitisrecommendedtouse

screwsinclass8.8.

canopyshouldbedesignedsothatthereisaminimum

clearanceof50mmbetweenthegeneratorairventand

anyflatsurface.

Thespacearoundtheairexitprotectiongridmustbe

free.

Thegenerator’srotorisdynamicallybalancedinfactory.

Theengineinducesquitecomplexvibrations,including

harmonicswithdifferentfrequencythat,whenaddedto

thegeneratorvibrations,cancausesubstantialvibration

levels dangerous for the generating set operation.

Thereforeitisessentialthattheplantengineertakesall

necessarymeasurestoensurealignmentandprovide

afirmbaseandsupportsinordertopreventvibrations

fromexceedingthestandard.

The alternator is designed to work with vibration’s

valuesasreportedinISO8528-9.

Alignment of single bearing generators is critical

becauseitmaygiverisetovibrationsalongthecoupling

betweenengineandgenerator.Forthispurposespecial

attention must be given to the alternator to engine

assembly, providing a solid base and implementing

anti-vibrationdamperstosupporttheengine/alternator

assembly.

Dual bearing generators require a rigid frame to

support theengine/generator so that a good base is

establishedforaprecisealignment.Thisframeshould

beanchoredtothebasewithanti-vibrationdampers.In

ordertominimizetwistoscillations,itisadvisabletouse

asuitablysizedflexiblejoint.

Inbelttransmissionsappliedtodualbearinggenerators

itisessentialthatthepulleydiametersandconstructions

permittheloadappliedtotheshafttobecentredwith

the length of the nub. The acceptable loads can be

requesteddirectlytotheSincro Technical Office.

Theterminalboxcontainstheinsulatedterminalsfor

connecting thephases and neutral and for the earth

connection.

The neutral is NOT connected to the housing.

Thegeneratorfaultcurrentsareavailableonrequest

to help the plant engineer in sizing the plant and its

components.

A drop in cooling air ow or inadequate

protection of the generator can lead

to damage and/or malfunction of the

windings.

WARNING!

The generator is supplied without

a connection to earth; to make this

connection refer to relevant local

regulations.Aninecientearthconnection

orsafetycut-outcancauseinjuryordeath.

WARNING!

Anerrorininstallation,use,maintenance

orreplacementofpartscancausesevere

injuryordeath,nottomentiondamageto

themachinery.Allworkonelectricaland/

or mechanical partsmust becarried out

byaqualiedspecialist.

WARNING!

An insucient loadbearing capacity can

causesevereinjuryanddamage.

CAUTION!

Theliftinglugsonthegeneratorhavebeen

designedforliftingonlythegeneratorand

notthewholegeneratingset.

CAUTION!

Beforeassembly,checkthatthecoupling

seats(bothongeneratorandengine)are

inorderandperfectlyclean.

CAUTION!

20

Loading...

Loading...