6.4.6 Wiring diagrams for different circuits

Intheappendixofthismanualtherearediagramsfor

connectionsotherthanthefactorystar-seriesconnec-

tion(standardunlessotherwisespeciedonorder).

6.4.7 Initial start-up

Beforestartingupthegeneratingsetcheckthatallex-

ternalconnectionsareinorderandthattheprotections

areinplace.

Duringtheinitialstart-uppayparticularattentionforany

unusualnoisethatmightsignalanincorrectalignment

betweenengineandgenerator.

Generatorsarerotatingelectricalmachinesthatinvolve

potentiallyhazardousliveormovingparts,thereforethe

followingisstrictlyprohibited:

• animproperuse;

• removalofcoversanddisconnectionofsafeties.

Dueto theseinherent hazards,all works ofelectrical

ormechanicalnaturemustbecarriedoutbyqualied

specialists.

7. AFTERSALES ASSISTANCE AND

MAINTENANCE

7.1 Control and check procedures

7.1.1 Control of windings and electrical insulation

The condition of the windings can be checked by

measuring their insulation resistance. While running

thistestdisconnectthevoltageregulatorandEMCfilter.

Itisusuallysufficienttocontrolthemainwinding.

The readings should give a measurement of at least

2 MOhm. If the insulation resistance is below this

threshold, the alternator alone should be oven dried

at 80 ÷ 100°C for 6 hours. Before carrying out this

operationremovethevoltageregulator.

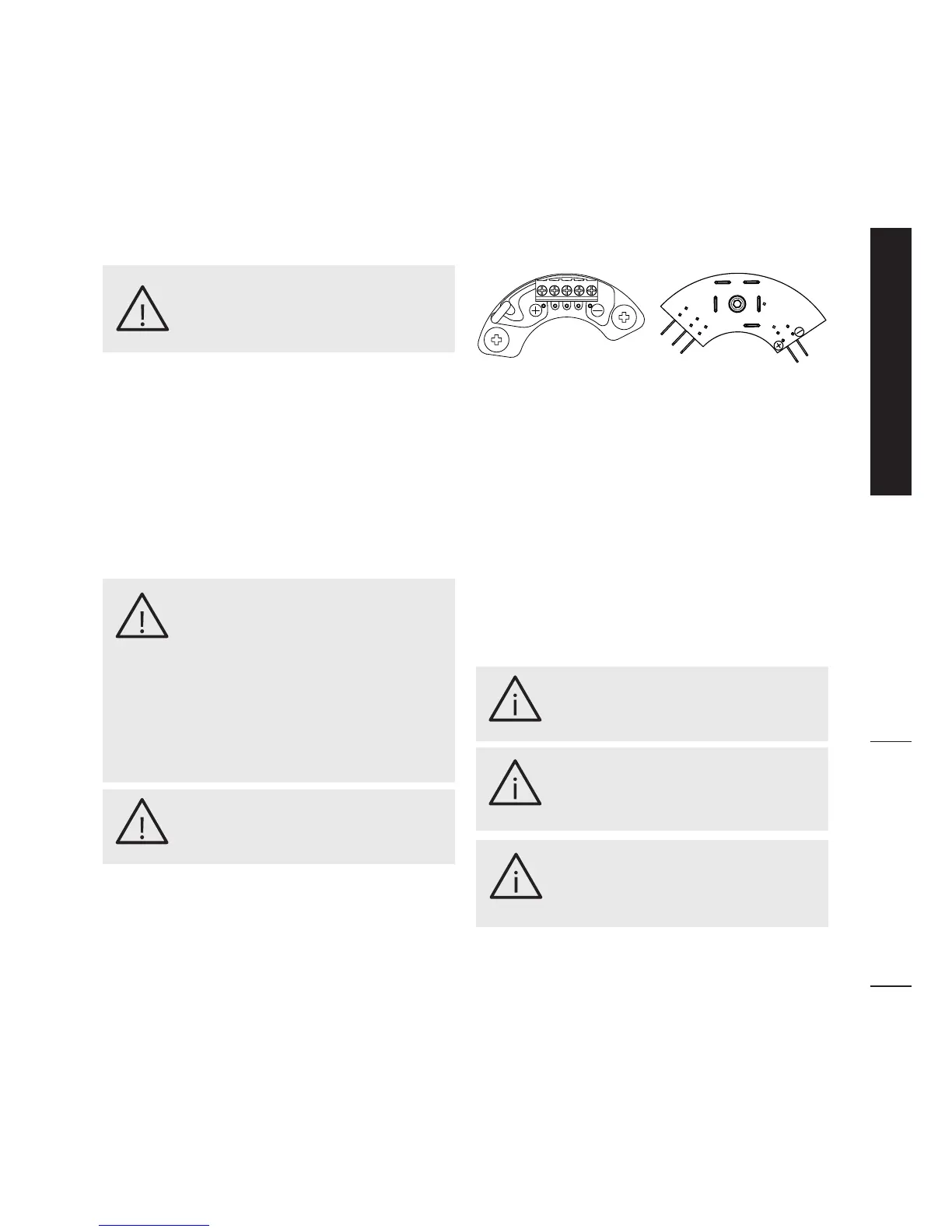

7.1.2 Control of the rotating rectifier diodes

This check can be performed with a multimeter, the

knob must be selected to the position “Diode test”.

The lead of each diode hasto beremoved fromthe

connectionswiththerotorexciter(seefigure),butit’s

not necessary to removed them from the alluminium

platewheretheyarefixed.

The faulty diode will have high (theoretically infinite)

resistance in both directions (open diode) or it can

havelowresistanceonbothdirections(diodeinshort)

by placing the tips on both directions. Meanwhile

thecorrectworking diode willhave low resistancein

forwarddirectionandhigh(theoreticallyinfinite)inthe

other(reverse)direction.

7.1.3 Control of bearings

During maintenance control the condition of the

bearings and check that no grease has leaked; the

lifespan of the bearings depends on the vibrations,

axial strains they undergo (vibrations can increase

considerablywithabadalignment)andontheworking

conditions.Socheckforanyunusualsigns:vibrations,

unusualnoises,cloggedairvents.

If undue vibrations or noises appear after long-term

usage, these could bedue to a worn bearingthat, if

damaged,hastobereplaced

The bearing should always be replaced after 20.000

working hours.

The lack of routine check-ups and poor

maintenance can causesevere damage

topersonsand/orobjects.

WARNING!

The maintenance and fault diagnostic

procedures involve risks that may

cause severe injury or even death.

These procedures should therefore be

carried out solely by qualied electrical

and mechanical specialists. Before any

maintenance and cleaning work make

surethattherearenoliveparts,thatthe

generatorhousinghascooledtoambient

temperature, that the generating set

cannotbeaccidentallystartedupandthat

allproceduresarestrictlyobserved.

WARNING!

Do not touch the generator while in

operation and immediatly after the

generatingsethasstopped,sincecertain

partsmaystillbeveryhot.

WARNING!

Long periods of sustained vibrations

can damage thebearing ballsand their

seat.Toohighhumiditycanemulsifythe

greaseandencouragecorrosion.

IMPORTANT!

Intense vibrations caused by the engine

bad alignment of the components inthe

generating set put the bearing under

stressesthatwillreduceitslifespan.

IMPORTANT!

Abearingslifespaniscloselylinkedtothe

workingconditionsandenvironment.

IMPORTANT!

IB

HB

Loading...

Loading...