- 17 -

16642

Version 02

EN

3. General description

EN

3. General description

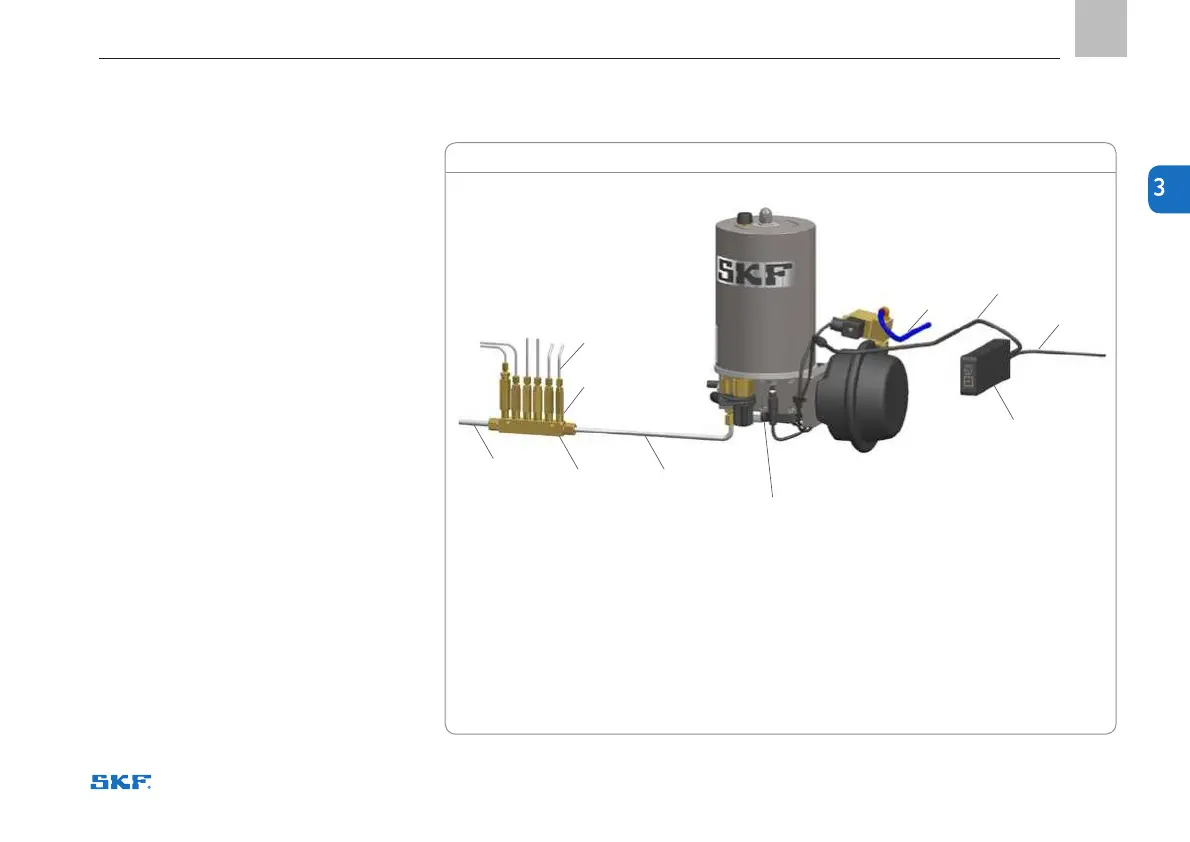

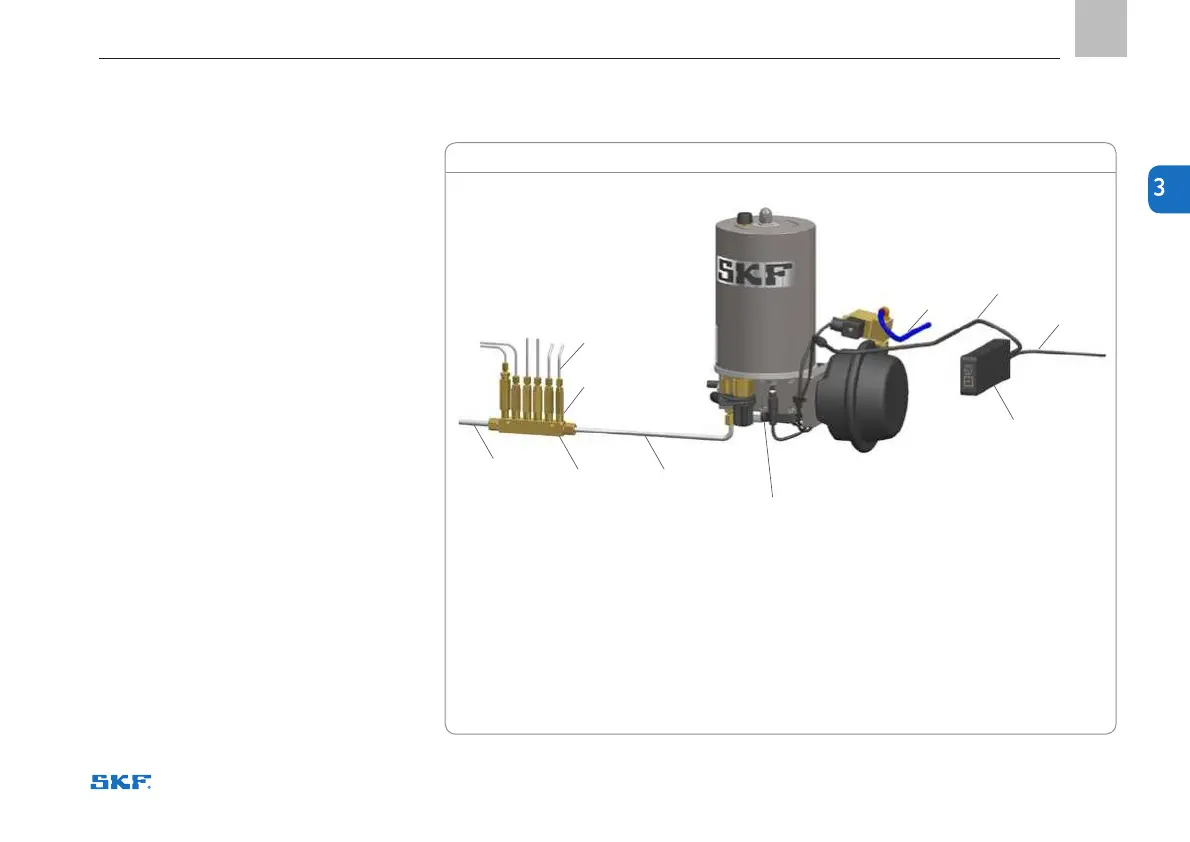

Figure 1

System operation

1. Control centre, e.g. ST-102 or ST-102P

2. 24 V DC power cable

3. Control cable

4. Pressurised air supply hose

5. Pump unit 40PGA

6. Header tube or hose

7. Mounting rail

8. B doser

9. Lubrication tube or hose

3.3 System operation

The system’s operation is controlled by a

control centre, such as the ST-102 (1),

which activates the pump at predetermined

intervals. At the start of a lubrication cycle,

a control impulse from the control centre

opens a solenoid valve, allowing pressurised

air to flow into the pump (5), increasing

the pressure in the piping. When the pres-

sure in the header piping (6) increases,

pressure-forced piston dosers (8) inject a

predetermined dose of lubricant through the

lubrication tube or hose (9) to the lubrication

point. At the end of the pressurisation stage,

the control centre reverts the pump to its

rest position, and both the pump and the

doser are filled with lubricant for the next

stroke. The control centre receives power

through a 24 V DC power supply cable (2).

There is also a control cable (3) between the

control centre and the pump.

System operation

2

9

4

3

8

6

7 6

1

5

Loading...

Loading...