152

Skycoded Module Section 5 – Procedures

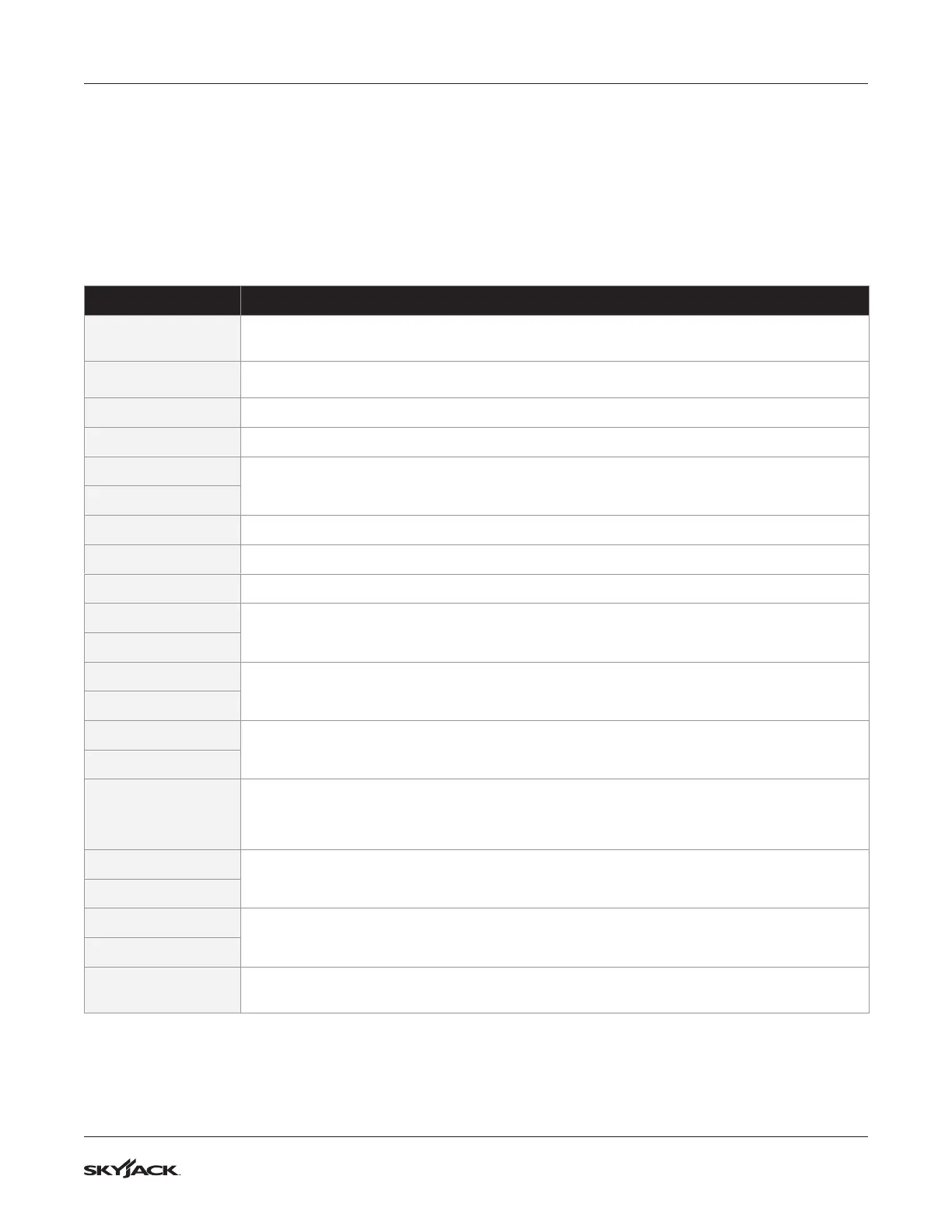

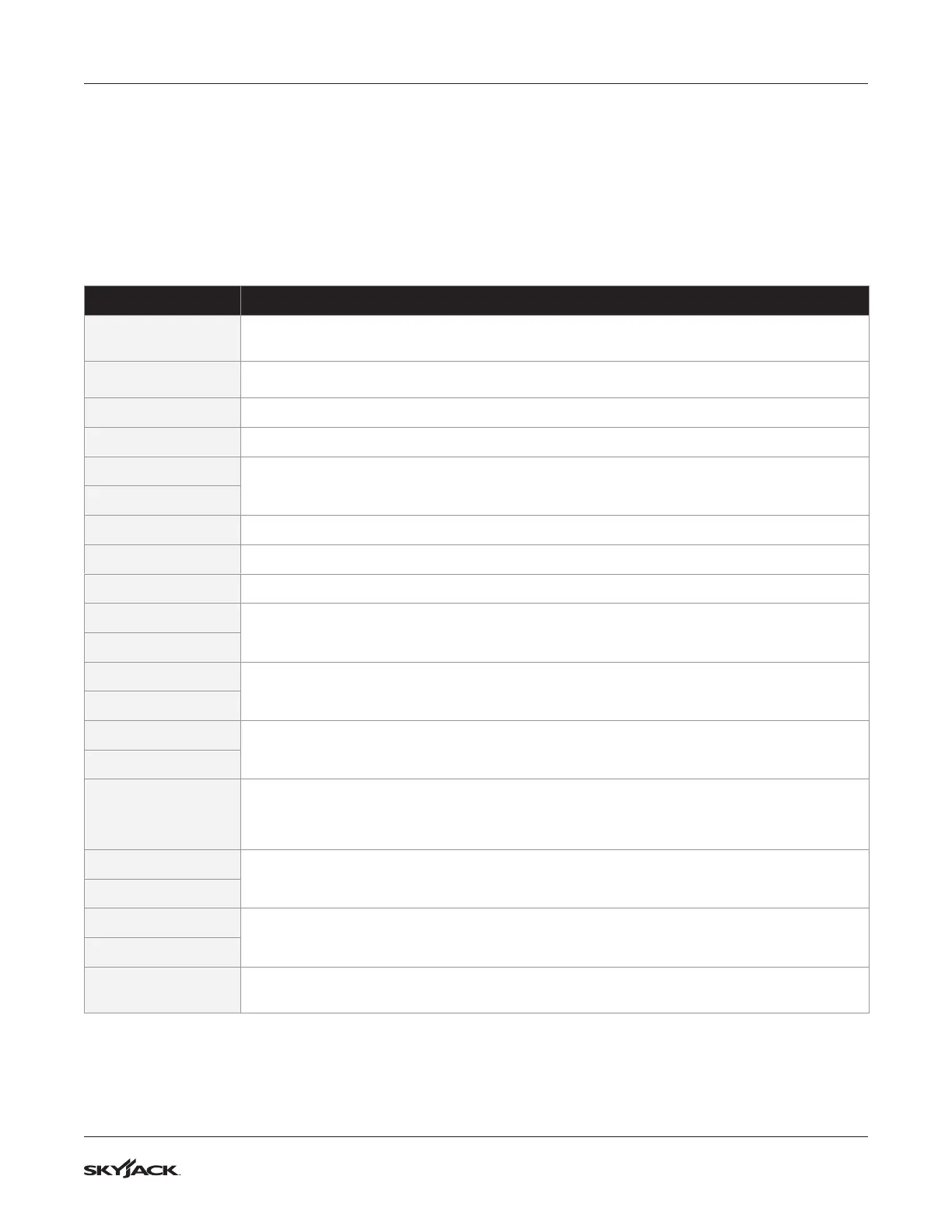

5.4-10 Callibration Fault Codes

During calibration, the Control Module CM1 repeatedly checks for possible problems, which might prevent

successful calibration, or subsequently give inaccurate platform load estimates.

If any problems are detected, a flashing error message is immediately displayed and calibration is terminated –

the problem must be resolved, and then calibration must be restarted.

Fault Code List

Most calibration error messages have an “Fxx” number as well as a description, to aid in trouble-shooting.

Fault Code Description

F01:CANNOT RUN

Something is wrong, preventing the Control Module CM1 from running – check the HELP message

(causes include line contactor, valve, or motor wiring errors).

F02:NOT GROUND

MODE

Calibration can only be carried out from base control!

F03:NOT STOPPED The machine must not already be moving when calibration started.

F04:TILTED The machine must be on level ground when calibration started.

F05:BAD HEIGHT1

At the start of calibration, the Angle Transducers are out of range (output must be between 0.9V and

4.1V with Platform fully lowered).

F05:BAD HEIGHT2

F06:CHECK ELEV At the start of calibration, the Angle Transducers require calibration with Platform fully lowered.

F07:BAD HEIGHTS During calibration, the two Angle Transducers disagreed too much.

F08:CHECK ELEV The Angle Transducers require calibration with the platform fully raised.

F09:BAD HEIGHT1

The Angle Transducers are out of range when fully lowered (0%) calibration is recorded (output

must be between 0.9V and 4.1V with platform fully lowered).

F09:BAD HEIGHT2

F10:BAD HEIGHT1

The Angle Transducers are out of range when fully raised (100%) calibration is recorded (output

must be between 0.6V and 4.4V with platform fully raised).

F10:BAD HEIGHT2

F11:NOT UP

When instructed to go up (raise the Platform) the DOWN switch was activated.

F11:NOT DOWN

F13:LOW HEIGHT

RANGE

There is not enough difference between the Angle Transducers output when fully lowered, and fully

raised (minimum allowed difference is 1V).

Make sure the UP switch is not released before the platform is fully raised.

F20:HEIGHT1<>0%

After fully raising and fully lowering the Platform, during dynamic or static calibration, we should

always be back at 0% height!

F20:HEIGHT2<>0%

F22:HEIGHT1<>100%

After fully raising the Platform, during static calibration, we should always lift to 100% height!

F22:HEIGHT2<>100%

F27:BAD HEIGHT

During static (loaded or empty) calibration, the platform height is out of range (below 0% or above

100%, or below 0.4V or above 4.6V).

Loading...

Loading...