205

Axles Section 5 – Procedures

5.9-8 Oscillating Cylinder Replacement

CAUTION

The oscillating axle cylinder weighs approximately

19.5 kg (43 lb), so a second person to assist with

the removal and replacement would be helpful.

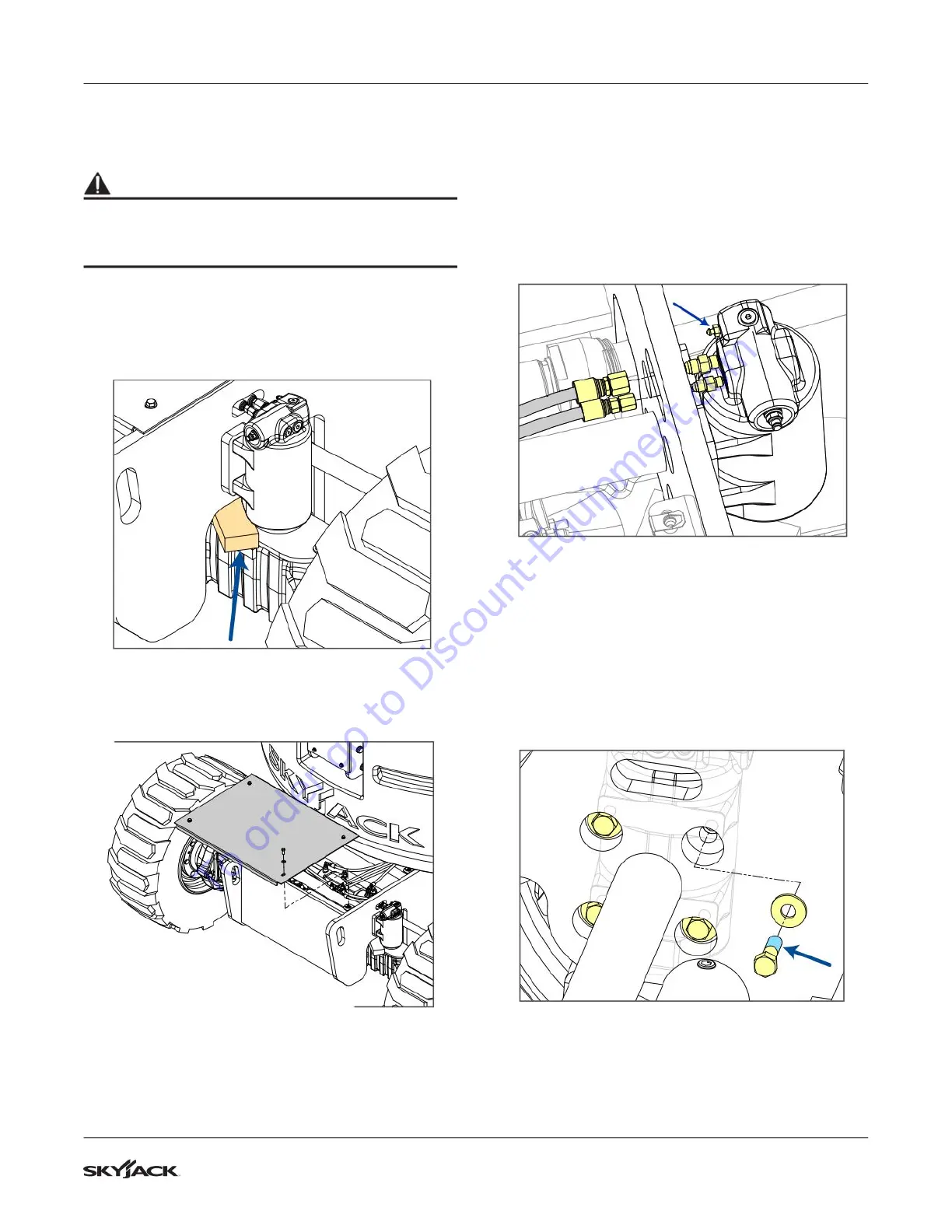

1. Wedge a block of wood between the front

axle and the chassis, to prevent the axle from

oscillating during the procedure.

2. Remove and set aside the base cover from the

oscillating axle end of the chassis.

3. With a rag in hand to catch any leaking oil,

slowly loosen the bleeder screw to release any

trapped air within the cylinder, then tighten it

again. Slowly loosen the oscillating axle cylinder

hoses to release the pressure, then disconnect

them fully, being sure to plug the hose ends.

4. Remove and set aside the cylinder fittings,

ensuring they stay clean.

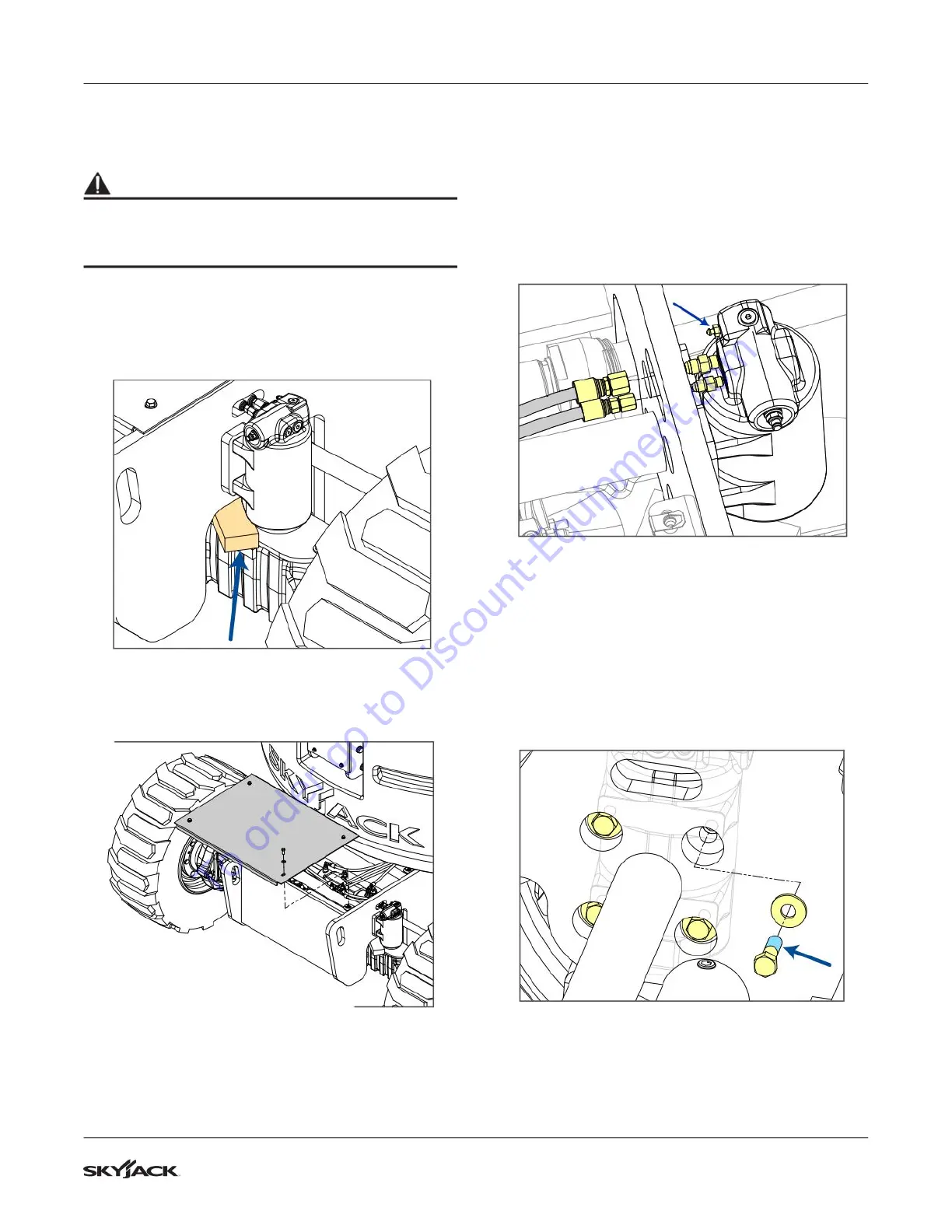

5. Remove and throw away the bolts and washers

securing the cylinder to the chassis. Lift the

cylinder away.

6. Lift a new cylinder into place and install

new bolts (1/2"-13 x 1-3/4" grade 8) and 1/2"

hardened washers, applying liquid blue Loctite

242 or 243 to the lower half of the bolts before

installing them. Hand tighten the bolts.

To order go to Discount-Equipment.com

Loading...

Loading...