22

Section 1 – Scheduled Maintenance Scheduled Maintenance Inspections

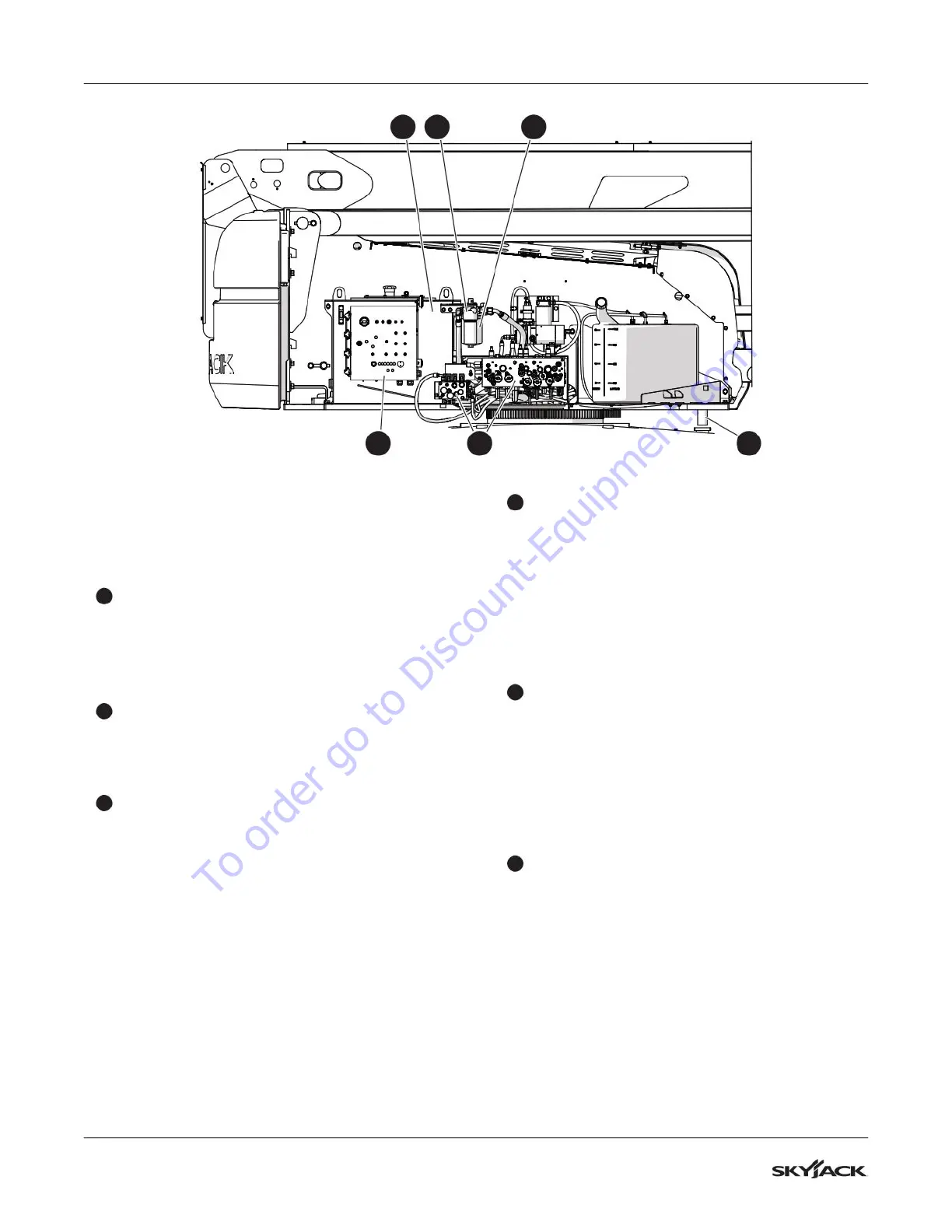

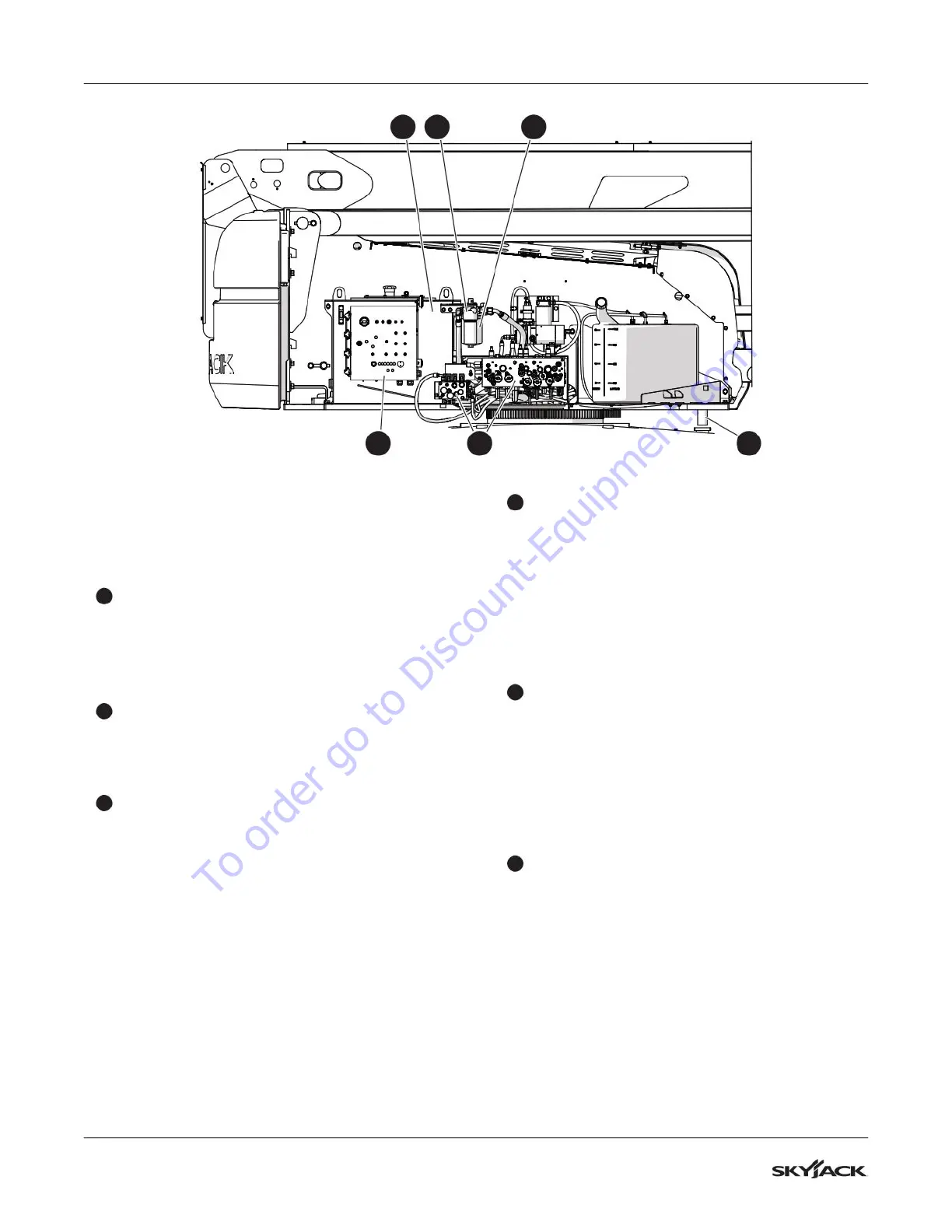

1.6-6 Control Compartment

Do the inspection that follows:

Make sure all compartment latches are latched tightly

and in good condition.

1

Turret transportation lock (B)

▪

Make sure the turret transportation lock is

unlocked.

▪

Make sure there are no loose or missing parts.

▪

Make sure there is no visible damage

2

Base Control Console (B)

▪

Make sure there are no loose or missing parts.

▪

Make sure there is no visible damage, and all

the switches are in their off/neutral positions.

3

Hydraulic Tank (B)

▪

Make sure the hydraulic filler cap closes

tightly.

▪

Make sure there is no visible damage or

hydraulic leaks.

Hydraulic Oil (B, C)

▪

Make sure the boom is in the stowed position.

▪

Do a check on the gauge on the side of the

hydraulic oil tank. The hydraulic oil level must

be at or a small distance above the top mark

of the gauge. Add oil if it is necessary. Refer to

2.13 Specifications and Features - Engines &

Fluids

C - Annual Inspection

▪

For the hydraulic oil replacement procedure,

refer to 5.7-2 Change the Hydraulic Oil.

4

Hydraulic Return Filter (B,C)

▪

Make sure the filter element is attached and

tight.

▪

Make sure there is no visible damage or

hydraulic leaks.

C - Annual Inspection

▪

For the hydraulic tank filter replacement

procedure, refer to 5.7-1 Change the Hydraulic

Tank Filter.

5

High-pressure filter (B,C)

▪

Make sure the housing is attached and tight.

▪

Make sure there is no visible damage or

hydraulic leaks.

C - Annual Inspection

▪

For the filter element replacement procedure,

refer to 5.5-1 Check and Replace the High

Pressure Filter.

6

Manifolds (B)

▪

Make sure all fittings and hoses are correctly

tightened.

▪

Make sure there is no indication of hydraulic

leakage.

▪

Make sure there are no loose wires or missing

fasteners.

▪

Ensure all fittings and hoses are properly

tightened and there is no evidence of hydraulic

leakage.

5 4

12 6

3

To order go to Discount-Equipment.com

Loading...

Loading...