LD301 – Operation and Maintenance Instruction Manual

6.8

Notes

(1) Meets NACE MR – 01 – 75/ISO 15156 recommendations.

(2) Without explosion proof or intrinsic safety approvals.

(3) Only available for differential and gage pressure models.

(4) Values limited to 4 1/2 digits, unit limited to 5 characters.

(5) Degrease cleaning not available for carbon steel flanges.

(6) Not applicable for saline atmosphere.

(7) IP66/68W tested for 200 hours according to NBR 8094 / ASTM B 117 standard.

(8) IPX8 tested in 10 meters of water column for 24 hours.

(9) Ingress Protection:

Product CEPEL NEMKO/EXAM FM CSA NEPSI

LD300 IP66/68W IP66/68W Type4X/6(6P) Type4X IP67

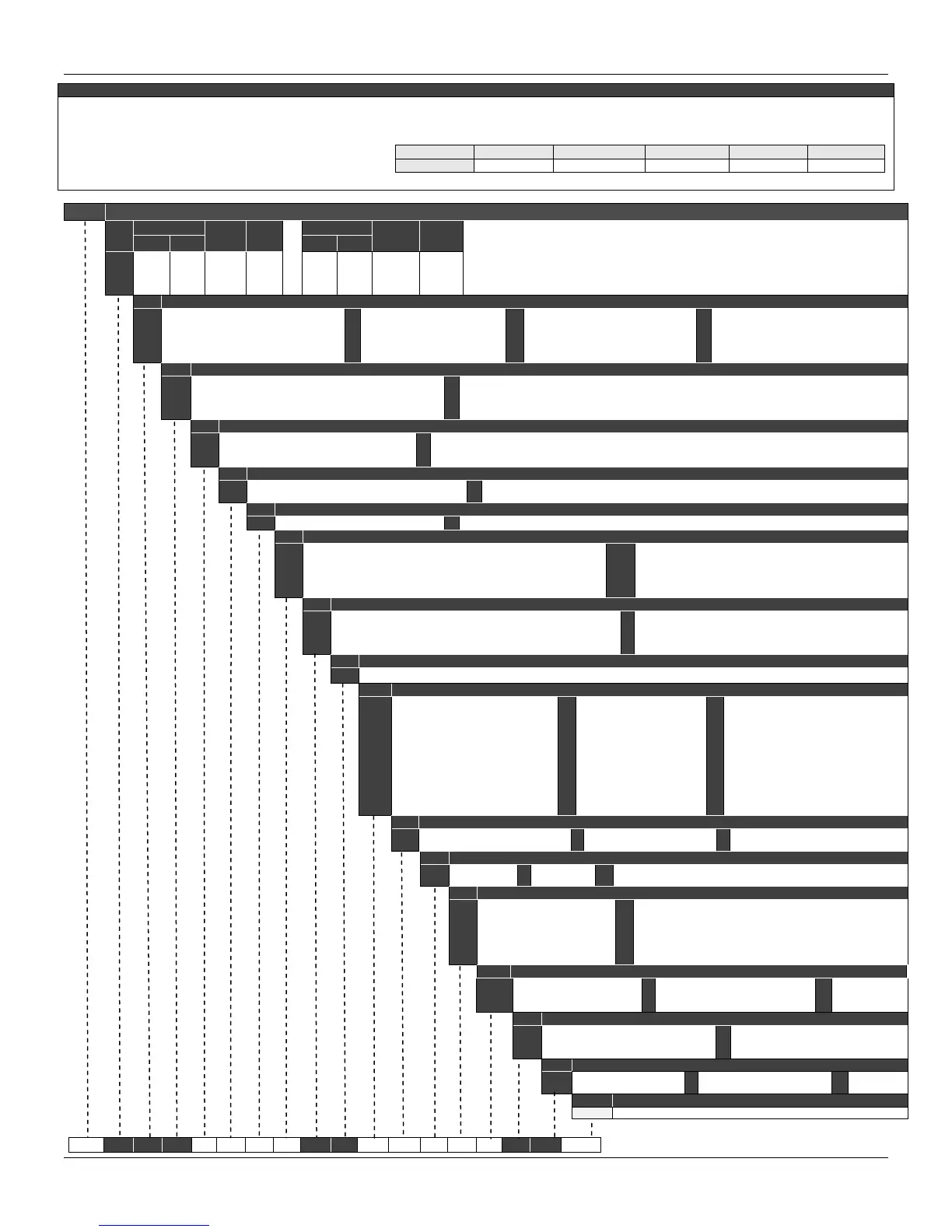

MODEL FLANGED PRESSURE TRANSMITTER

COD.

Range Limits

Min.

Span

Unit

Range limits

Min.

Span

Unit

Note: The range can be extended up to 0.75 LRL and 1.2 URL with small degradation of accuracy. The

upper range value must be limited to the flange rating.

Min. Max. Min. Max.

L2

L3

L4

L5

-50

-250

-2500

-25000

50

250

2500

25000

1.25

2.08

20.83

208.3

kPa

kPa

kPa

kPa

-200

-14,7

-14,7

-14,7

200

36

360

3600

0,42

2,08

20,83

0,21

inH

2

O

psi

psi

psi

COD.

Diaphragm material and Fill Fluid (Low Side)

1

2

3

4

5

316L SST

316L SST

Hastelloy C276

Hastelloy C276

Monel 400

Silicone Oil (2)

Inert Oil Fluorolube(3)(21)

Silicone Oil (1) (2)

Inert Oil Fluorolube (1)(3)(21)

Silicone Oil (1) (2)

7

8

9

A

D

Tantalum

Tantalum

316L SST

Monel 400

316L SST

Silicone Oil (2)

Inert Oil Fluorolube (3) (21)

Fomblim Oil

Fomblim Oil (1)

Inert Oil Krytox (21)

E

G

K

M

P

Hastelloy C276

Tantalum

Monel 400

Monel 400 Gold Plated

Monel 400 Gold Plated

Inert Oil Krytox (1)(21)

Inert Oil Krytox (21)

Inert Oil Krytox (1) (21)

Silicone Oil (1) (2)

Inert Oil Krytox (1) (21)

Q

R

S

316L SST

Hastelloy

C276

Tantalum

Inert Oil Halocarbon 4.2 (21)

Inert Oil Halocarbon 4.2 (1) (21)

Inert Oil Halocarbon 4.2 (21)

COD.

Flange, Adapter and Drain/Vent Valves material (Low Side)

A

C

H

I

304L SST

Plated CS (Drain/Vent in Stainless Steel) (22)

Hastelloy C276 (CW – 12MW, ASTM – A494) (1)

316 SST – CF8M (ASTM – A351)

M

N

P

Monel 400 (1)

316 SST – CF8M (ASTM – A351) (Drain/Vent in Hastelloy C276) (1)

316 SST – CF8M (ASTM – A351) Flange with PVDF (Kynar) insert (3) (4) (5)

COD.

Wetted O’Ring Material (Low Side)

0

B

E

Without O’Rings

Buna-N

Ethylene - Propylene

K

T

V

Kalrez

Teflon

Viton

Note: O’rings are not available on the sides with remote seals.

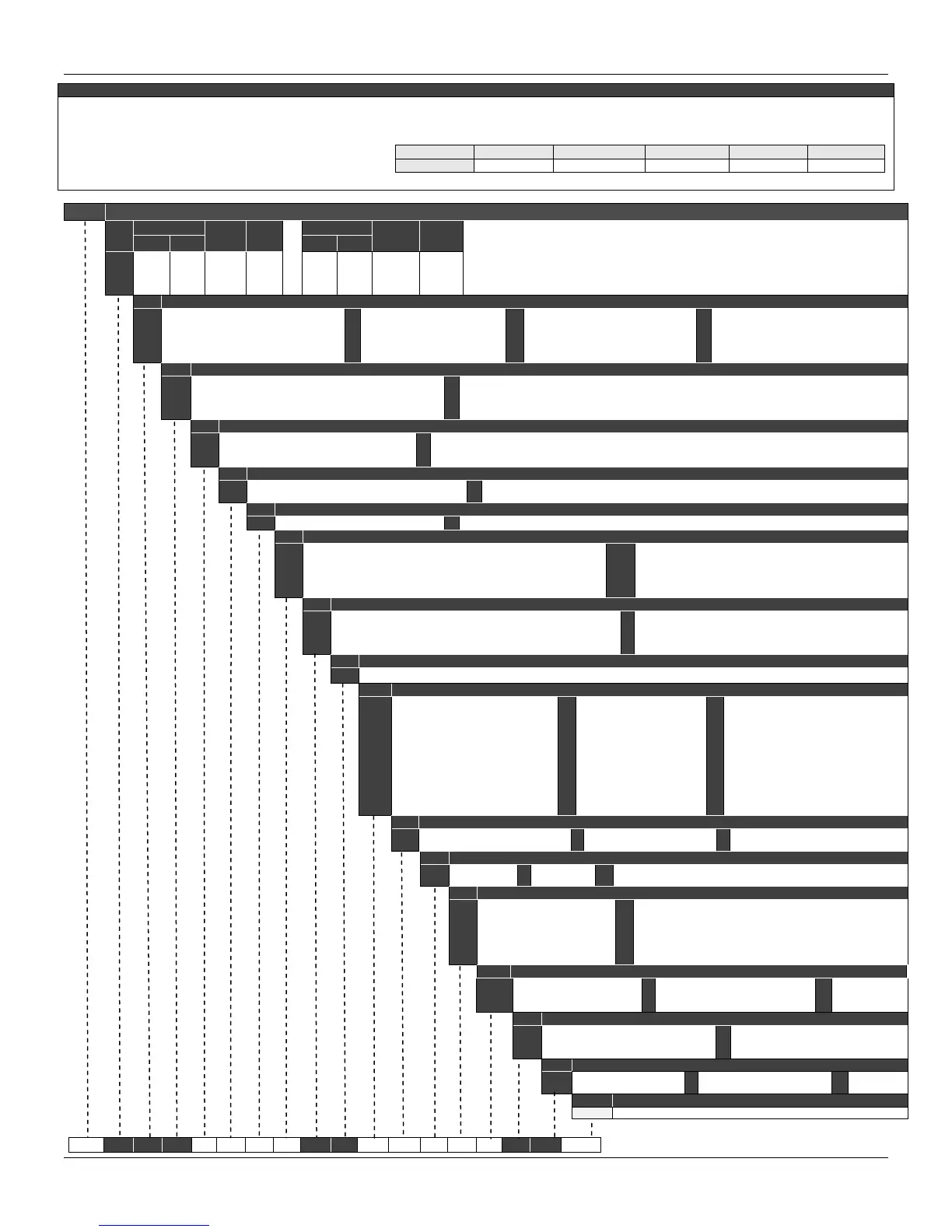

COD.

Drain/Vent Position (Low Side)

0

A

Without Drain/Vent

Drain/Vent (Opposite to Process Connection)

D

U

Bottom

Top

Note: For better Drain/Vent operation, vent valves are strongly

recommended. Drain/Vent valve are not available on the sides with remote seals.

COD.

Local Indicator

0

Without Indicator 1 With Digital indicator

COD.

Process Connection (Low Side)

0

1

3

5

9

1/4 - 18 NPT (Without Adapter)

1/2 - 14 NPT (With Adapter)

Remote Seal (With Plug ) (7)

1/2 - 14 NPT Axial with PVDF Insert (3) (4) (6)

Remote Seal (Low Volume Flange) (3) (7)

T

U

V

W

1/2 14 BSP (With Adapter)

Low Volume Flange For Level Welded

Without Connection (Mounting With Gage Flange)

Without Connection (Absolut Reference)

COD.

Electrical Connection

0

1

2

3

1/2 – 14 NPT (27)

3/4 – 14 NPT (with 316 SST adapter for ½ - 14 NPT) (24)

3/4 – 14 BSP (with 316 SST adapter for ½ - 14 NPT) (9)

1/2 – 14BSP (with 316 SST adapter for ½ - 14 NPT) (9)

B

Z

M20 x 1.5 (28)

PG 13.5 DIN (28)

User’s specification

COD.

Zero and Span Adjust

1 With Zero and Span Adjustment

COD.

Process Connection

U

V

W

O

P

Q

9

A

B

1

2

1” 150 # (ANSI B16.5) (31)

1” 300 # (ANSI B16.5) (31)

1” 600 # (ANSI B16.5) (31)

1.1/2” 150 # (ANSI B16.5)

1.1/2” 300 # (ANSI B16.5)

1.1/2” 600 # (ANSI B16.5)

2” 150 # (ANSI B16.5)

2” 300 # (ANSI B16.5)

2” 600 # (ANSI B16.5)

3” 150 # (ANSI B16.5)

3” 300 # (ANSI B16.5)

C

N

3

4

D

5

R

E

6

7

8

3” 600 # (ANSI B16.5)

3” 600 # (ANSI B16.5 RTJ)

4” 150 # (ANSI B16.5)

4” 300 # (ANSI B16.5)

4” 600 # (ANSI B16.5)

DN25 PN 10/40 (31)

DN 40 PN 10/40

DN 50 PN 10/40

DN 80 PN 10/40

DN 100 PN 10/16

DN 100 PN 25/40

S

F

T

K

G

L

H

M

Z

JIS 40A 20K (25)

JIS 50A 10K (25)

JIS 50A 40K (25)

JIS 50A 20K (25)

JIS 80A 10K (25)

JIS 80A 20K (25)

JIS 100A 10K (25)

JIS 100A 10K (25)

User’s specification

COD.

Type and Flange Material ( Level Tap)

2

3

316L SST (Integral Flange)

Hastelloy C276 (Integral Flange)

4

5

304 SST (Slip-on Flange)

316 SST (Slip-on Flange)

6

Z

Carbon Steel (Slip-on Flange)

User’s specification

COD.

Extension Length

0

1

0 mm (0”)

50 mm (2”)

2

3

100 mm (4”)

150 mm (6”)

4

Z

200 mm (8”)

User’s specification Note: Extension Material 316L SST

COD.

Diaphragm Material / Extension (Level Tap)

1

2

3

4

5

304L SST / 304L SST

316L SST / 316 SST

Hastelloy C276 / 316 SST

Monel 400 / 316 SST

Tantalum / 316 SST (10)

Titanium / 316 SST (10)

6

7

B

L

C

316L SST with Teflon Lining (For 2”and 3”)

316L SST Gold plated

Tantalum with Teflon Lining

316L SST Halar Plated (20)

Hastelloy Teflon Plated

COD.

Fill Fluid

1

3

2

DC – 200/20 Silicone Oil

DC704 Silicone Oil

MO – 10 Fluorolube Oil (8)

4

N

G

Krytox Oil

Neobee M20 Propylene Glycol Oil

Glycerin (6)

B

H

T

Fomblim 06/06

Halocarbon 4.2

Syltherm 800 Oil

COD.

Housing Material

0

1

2

Without Gaskets (12)

316 SST

Hastelloy C276

3

4

5

Super Duplex (UNS 32750) (11)

Duplex (UNS 31803) (11)

Stainless Steel 304L (11)

COD.

Gasket Material

0

T

Without gasket

Teflon (PTFE)

G

C

Grafoil (Flexible lead)

Copper

I 316 L SST

COD.

Continues Next Page

TYPICAL MODEL NUMBER

LD301 L2 1 I B U 1 0 0 1 1 2 2 1 1 1 T

Loading...

Loading...