Technical Characteristics

6.9

LD301

FLANGED PRESSURE TRANSMITTER (CONTINUATION)

COD.

Flanges Bolts and Nuts Material

A0

A1

Plated Carbon Steel (Default) (22)

316 SST

2

A5

Carbon Steel (ASTM A193 B7M) (1) (22)

Hastelloy C276

COD

Flange Thread for Fixing Accessories (Adapters, Manifolds, Mounting Brackets, etc)

D0 7/16” UNF (Default) D1 M10 X 1.5 Thread D2 M12 X 1.75

COD.

Flange Facing Finish

Q0

Q1

Raised Face – RF (Default)

Flat Face – FF

Q2

Q3

Ring Joint Face – RTJ (Only available for ANSI standard flange) (17)

Tongue Face (11)

Q4 Grooved Face (11)

COD.

Output Signal

G0 4 – 20 mA (Default) G1 0 – 20 mA (4 wire) (13) G3 NAMUR NE extended 4-20 mA (Burnout 3,55 to 22,8 mA)

COD.

Housing Material (29) (30)

H0 Aluminum (Default) H1 316 SST – CF8M ASTM – A351) H2 Aluminium (23) H3 316 SST (23) H4 Copperfree Aluminium (23)

COD.

Tag Plate

J0

With tag, when specified (Default) J1 Blank J2 According to user’s notes

COD.

PID Configuration

M0

With PID (Default) M1 Without PID

COD.

LCD1 Indication

Y0

Y1

LCD1: Percentage (Default)

LCD1: Current – I (mA)

Y2

Y3

LCD1: Pressure (Engineering Unit)

LCD1: Temperature (Engineering Unit)

YU

LCD1: According to user notes (3)

COD.

LCD2 Indication

Y0

Y4

LCD2: Percentage (Default)

LCD2: Current – I (mA)

Y5

Y6

LCD2: Pressure (Engineering Unit)

LCD2: Temperature (Engineering Unit)

YU

LCD2: According to user notes (3)

COD.

Identification Plate

I1

I2

I3

I4

FM: XP, IS, NI, DI

NEMKO: Ex-d, Ex-ia

CSA: XP, IS, NI, DI

EXAM (DMT): Ex-ia

I5

I6

I7

CEPEL: Ex-d, Ex-ia

Without Certification

EXAM (DMT): Group I, M1 Ex-ia

I8

IF

IM

0 to 20 mA: LD301 (13)

CEPEL: Ex-d

BDSR-GOST: Ex-d, Ex-ia

COD.

Painting

P0

P3

P4

P5

Gray Munsell N6,5 Polyesters

Black Polyester

White Epoxy

Yellow Polyester

P8

P9

PC

Without Painting

Blue Safety Epoxy – Electrostatic Painting

Blue Safety Polyesters – Electrostatic Painting

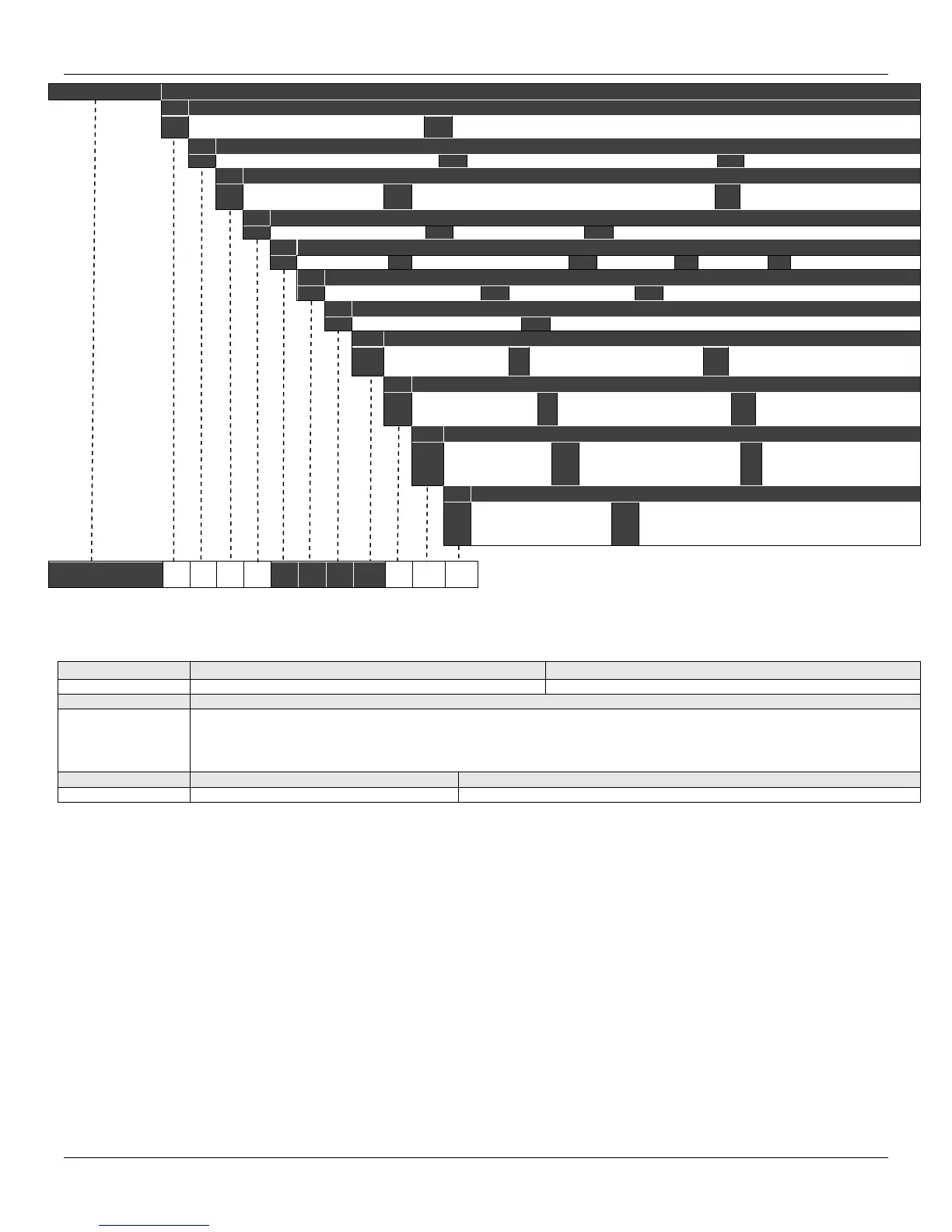

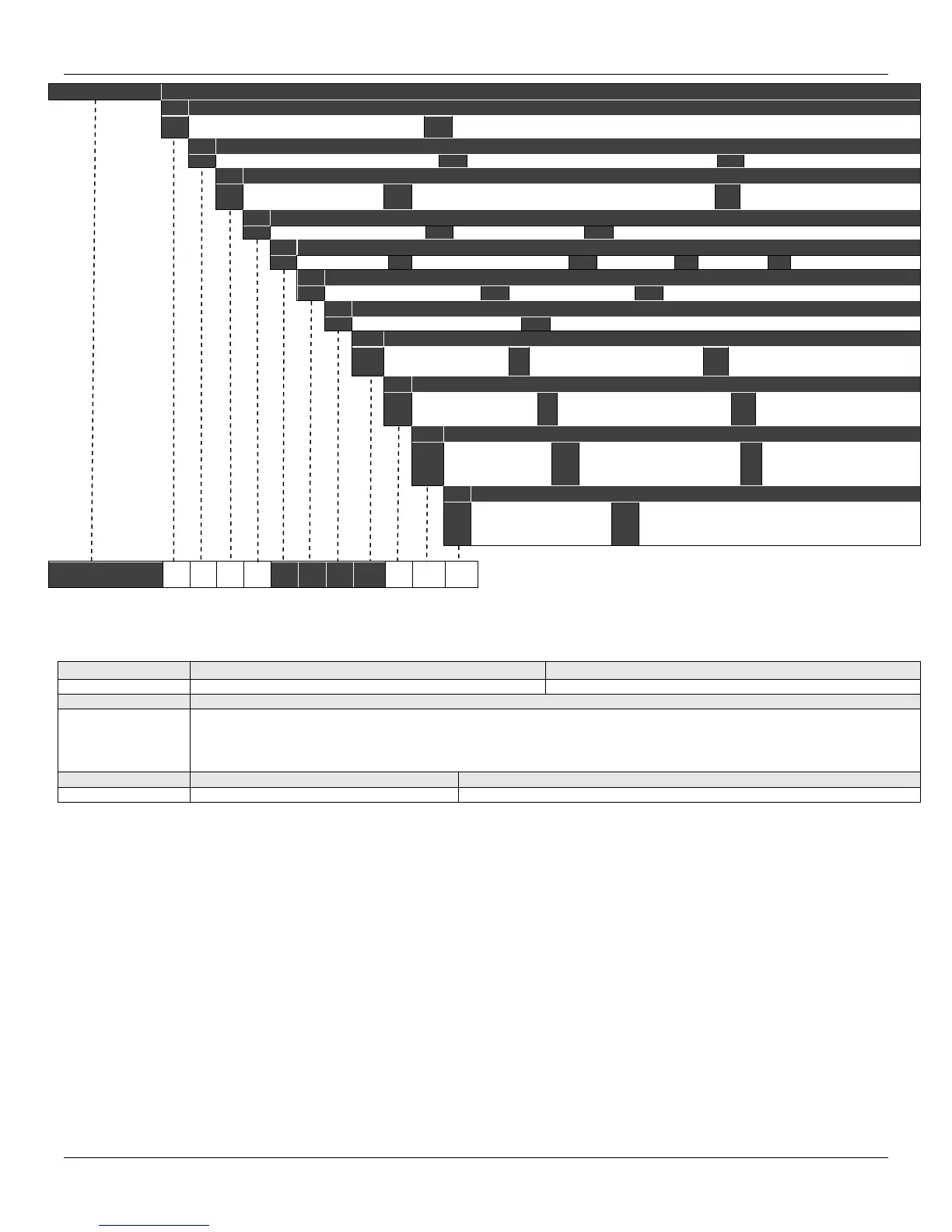

TYPICAL MODEL NUMBER

Optional Items

* Leave blank for no optional items

Burn-out BD - Down Scale (Accordance to NAMUR NE43 specification) BU - Up Scale (Accordance to NAMUR NE43 specification).

Special Applications C1 - Degrease Cleaning (Oxygen or Chlorine Service (4) C2 - For vacuum application.

Special Features ZZ - User’s specification.

Gasket Connection

U0 - With one Flush Connection ¼” NPT (if supplied with gasket)

U1- With two Flush Connections ¼” NPT per 180 ºC

U2 - With two Flush Connections ¼” NPT per 90 ºC

U3 - With two Flush Connections ½” NPT - 14 NPT per 180 ºC (with cover)

U4 - Without Gasket Connection

Isolator Kit (16) K0 - Without Kit K1 - With Kit

Diaphragm Thickness N0 – Default (26) N1 - 0.1mm (11)

LD301-L2I-BU10-01-

12211

A0 D0 F0 G0

H0 J0 M0 Y0 Y0 I6 P0

Loading...

Loading...