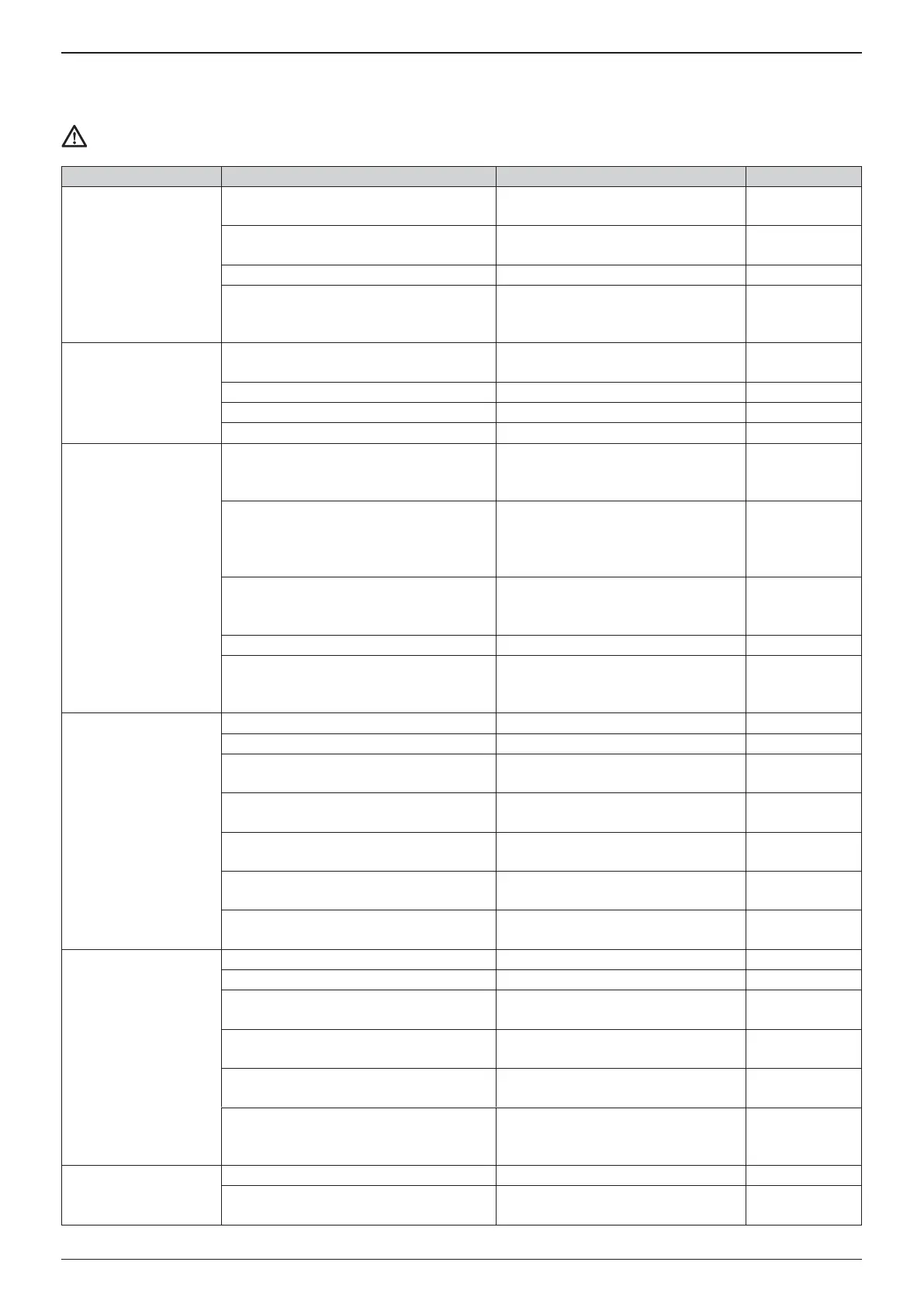

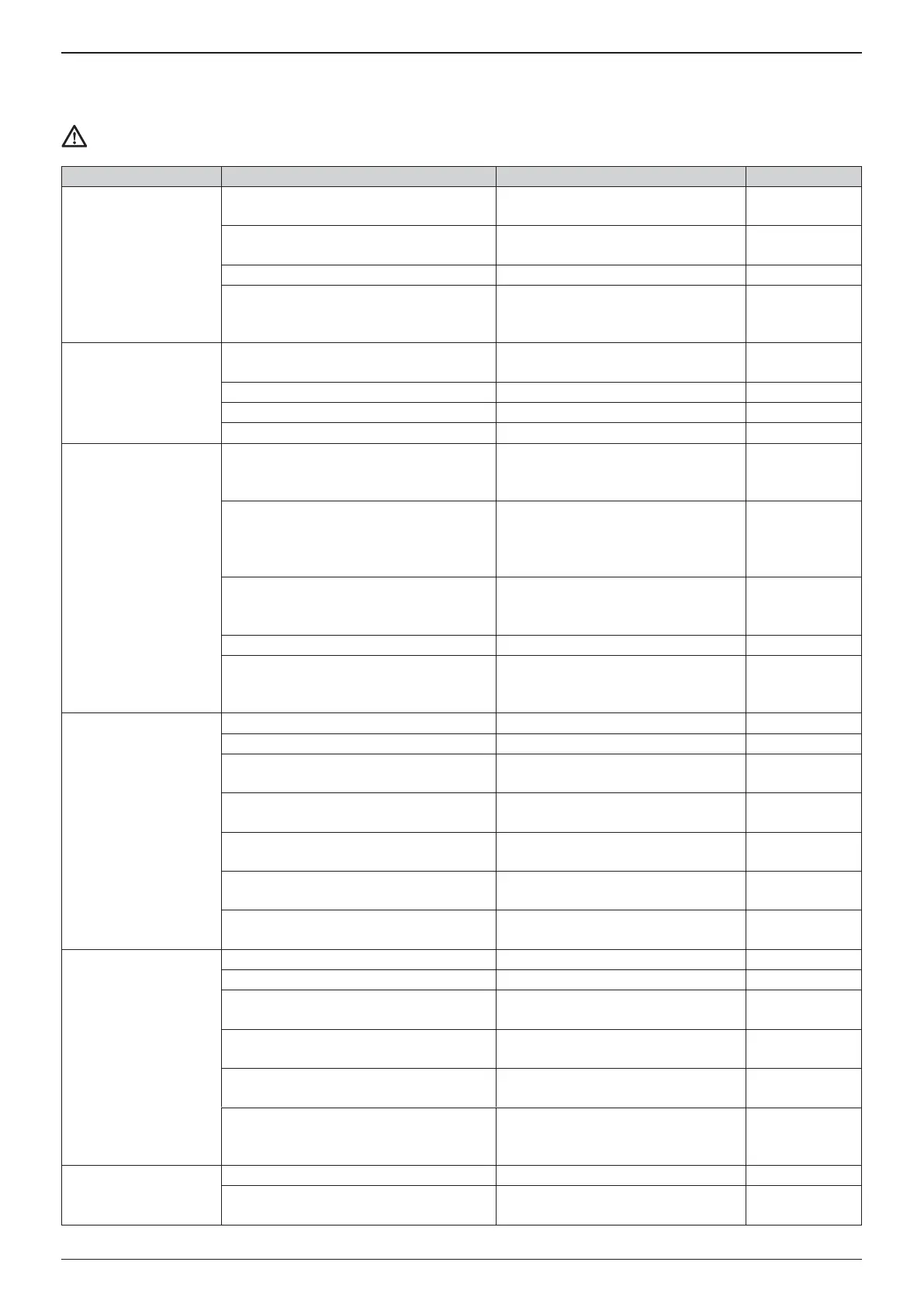

10. PB2500SMART TROUBLESHOOTING GUIDE

WARNING: Read instruction manual for tool itself together to understand the troubleshooting of tool.

Symptom Cause Remedy Page

Power does not turn

on.

1. Battery is not fully seated Remove battery and re-insert. Reset

tool to home.

Refer to tool

manual

2. Battery is not fully charged Charge battery Refer to tool

manual

3. Battery is defective Replace battery -

4. Battery pack has reached operating

temperature limit through continuous

use or defect

Remove battery & allow to cool.

Mount battery and reset tool to

home.

-

Screen freezes in

Stanley Engineered

Fastening Logo.

1. Data reading fails Remove battery and re-insert. Press

trigger to turn on.

-

2. Smart screen is defective Contact a local service center -

3. Trigger module is defective Replace motor & module assembly -

4. Setting data are broken Restore to factory settings 31

Tool does not operate

when trigger switch is

pressed.

1. Screen is not home screen (Counter

screen)

Change screen to home screen.

Touch “Back home” icon to be back

home.

9

2. Screen freezes

Even if touch screen, screen doesn not

respond or screen becomes all white.

Remove battery and re-insert. Press

trigger to turn on.

If does not revert, contact local

service center.

-

3. Alarm message is shown with beep

sound.

Reset alarm refering to the related

pages.

each

4. Setting data are broken Restore to factory settings 31

5. Radio communication error Even if restores to factory settings, if

does not revert, contact local servicre

center.

-

Tool shows NOK, even

if it sets rivet correctly.

1. Judgement range setting is not correct Set judgement range correctly 15, 16

2. Judgement range setting is too small Set appropriate range 15, 16

3. Not fasten 5 rivets in average mode Fasten 5 rivets, if it has an error, do it

again

15

4. Jaw slips. Do maintenane around jaw area Refer to tool

manual

5. Tool is not at home position Reset tool to home Refer to tool

manual

6. There is a problem in tool. Remove cause of issue or contact

local service center

-

7. Trigger module is defective. Replace motor & module assembly or

contact local service center

-

Tool does not show

NOK, even if it sets

incorrect rivet

1. Judgement range setting is not correct Set judgement range correctly 15, 16

2. Judgement range setting is too largel Set appropriate range 15, 16

3. Not fasten 5 rivets in average mode Fasten 5 rivets, if it has an error, do it

again

15

4. There is a problem in tool. Remove cause of issue or contact

local service center

-

5. Trigger module is defective. Replace motor & module assembly or

contact local service center

-

6. Smart function is turned o . No NOK judgement if smart function

is turned o .

If needed, turn on smart function

14

Screen does not show

process curve or does

not show correctly.

1. Smart function is turned o . Turn on smart function 14

2. Rivet break load is small, it is under

3,000N

Turn o smart function, if low break

load rivets are used

8, 14

37

ENGLISH

Loading...

Loading...