4-2

10083002 Operator Manual Post Installation Verification

4.2 Check

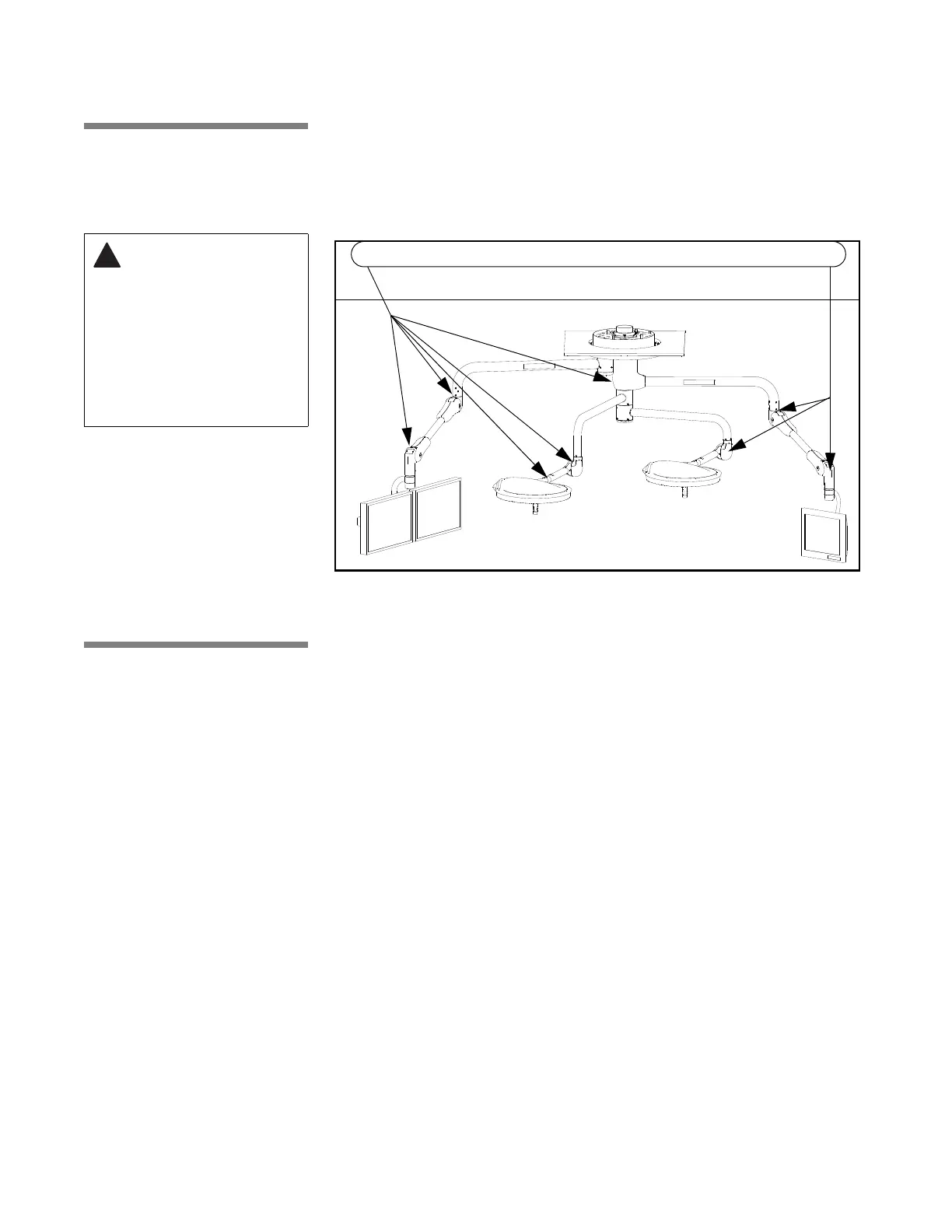

Suspension

Movement

Check all suspension joints for compromised integrity, such as loose

fasteners or components. Refer to Figure 4-2 for typical points on the

suspension.

Verify that suspension system moves through all articulations smoothly without

binding. Lightheads and monitors should move smoothly and easily. When

positioned, the lighthead and monitor support arms should not drift. If binding

or drifting is present in suspension movements, call your STERIS service

representative to make adjustments.

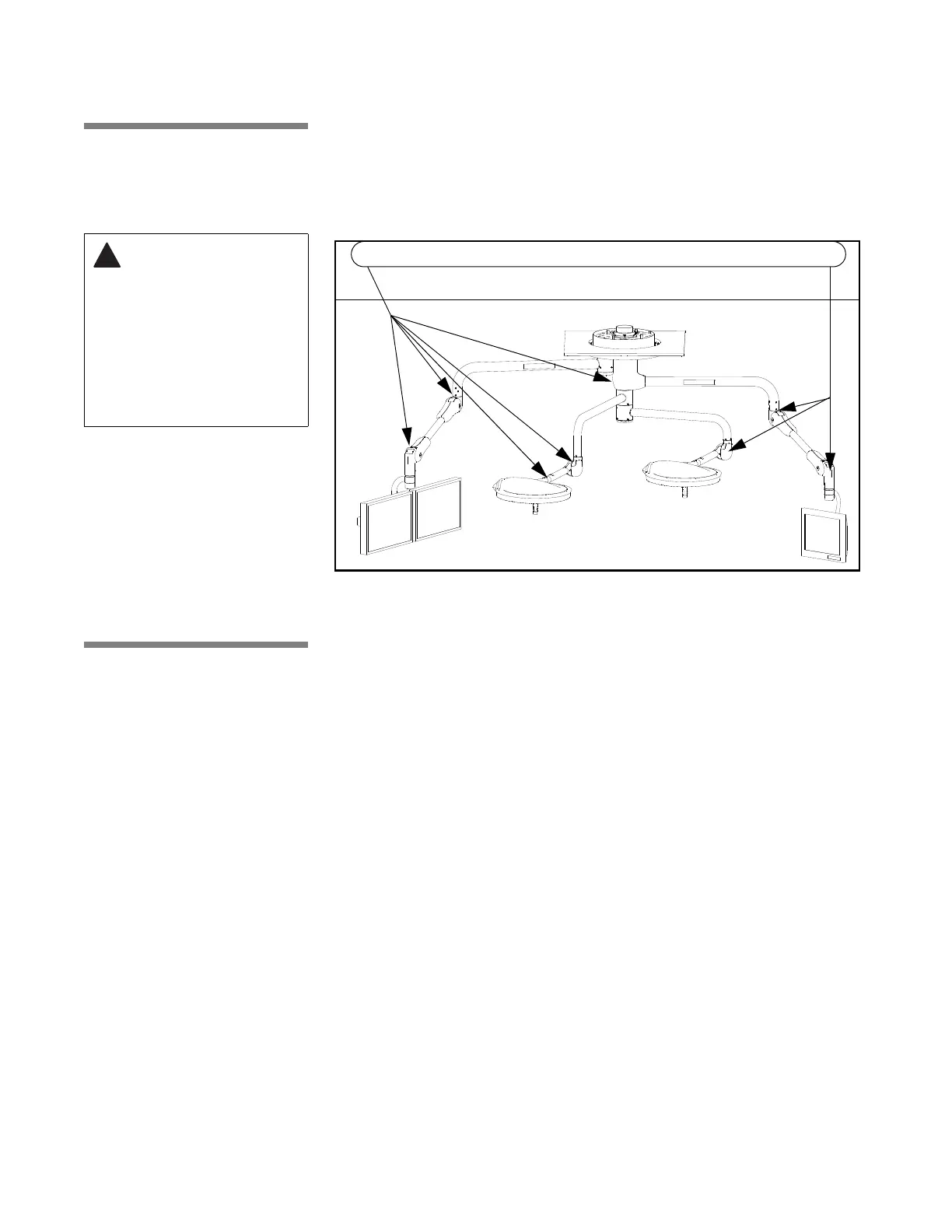

4.3 Monitor Arms Refer to Figure 4-3. Flat panel monitor support arms are capable of the

following articulations: (1) rotate 240° at the secondary spindle; (2) rotate 320°

at the central spindle; (3) rotate 310° at the horizontal extension arm; (4) rotate

320° at the spring arm/yoke transition; (5) move up or down by pivoting at

spring arm knuckle up to 40° up, and 40° down. Flat panel yoke also allows

(6) tilt15° backward (up) and 90° forward (down).

• For additional information, refer to separate operating instructions

supplied with monitor(s). (Monitor instructions not by STERIS.)

• Power supply and input signals to monitors can be routed through the

suspension wiring from an external video source (external video sources

not provided by STERIS).

• Range of upward motion for spring arm can be adjusted to 20°, 30° or 40°

above horizontal to expand storage/parking options when monitors are not

in use.

If weight or range of motion for flat panel monitor mount system is changed in

any way, refer to I

NSTALLATION INSTRUCTIONS, 10043126 for procedures to help

ensure proper balancing and motion.

WARNING – PINCHING

HAZARD: Pinch points

are created during

extreme articulation of

the suspension

system. Do not place

hands on or near the

suspension knuckle

during lighthead

articulations.

Figure 4-2. Check Suspension

Check these, and all similar areas for ease of movement, as well as suspension integrity

Loading...

Loading...