43TS 410, TS 420

: Fit washers and nuts (arrows).

– Screw the nuts tight.

: Turn the spindle (1)

counterclockwise until the

crankshaft has been forced out of

the ignition-side half of the

crankcase.

: The crankshaft (1), connecting

rod (2) and the needle bearing

between them make up a

complete unit and must therefore

always be replaced as a unit.

– Check the two halves of the

crankcase and the grooved ball

bearing, replace if necessary,

b 7.6.2.

370RA142 TG

21

21

21

21

370RA143 TG

1

370RA144 TG

2

1

Before installing the crankshaft,

it must be cleaned with standard

solvent-based degreasant not

containing any chlorinated or

halogenated hydrocarbons.

Installing the ignition-side half of

the crankcase

Avoid damage to the crankshaft

stub.

Examine and clean the mating

surfaces of the ignition-side half of

the crankcase (including the

cylinder sealing surface). The

mating surfaces must not be

damaged in any way whatsoever.

– Line the crankshaft up with the

conical stub (arrow) pointing

towards the grooved ball bearing

on the ignition side.

Wear protective gloves – risk of

burns.

– Heat the inner race of the ball

bearing to approx. 150 °C

(300 °F).

Push the crankshaft home until the

crankshaft stub makes contact.

The crankshaft must be fitted

rapidly, as the heat is transmitted to

the crankshaft stub and the inner

bearing race contracts.

370RA145 TG

If the inner race cannot be heated,

the crankshaft can be drawn into the

crankcase with the installing tool

5910 893 2102.

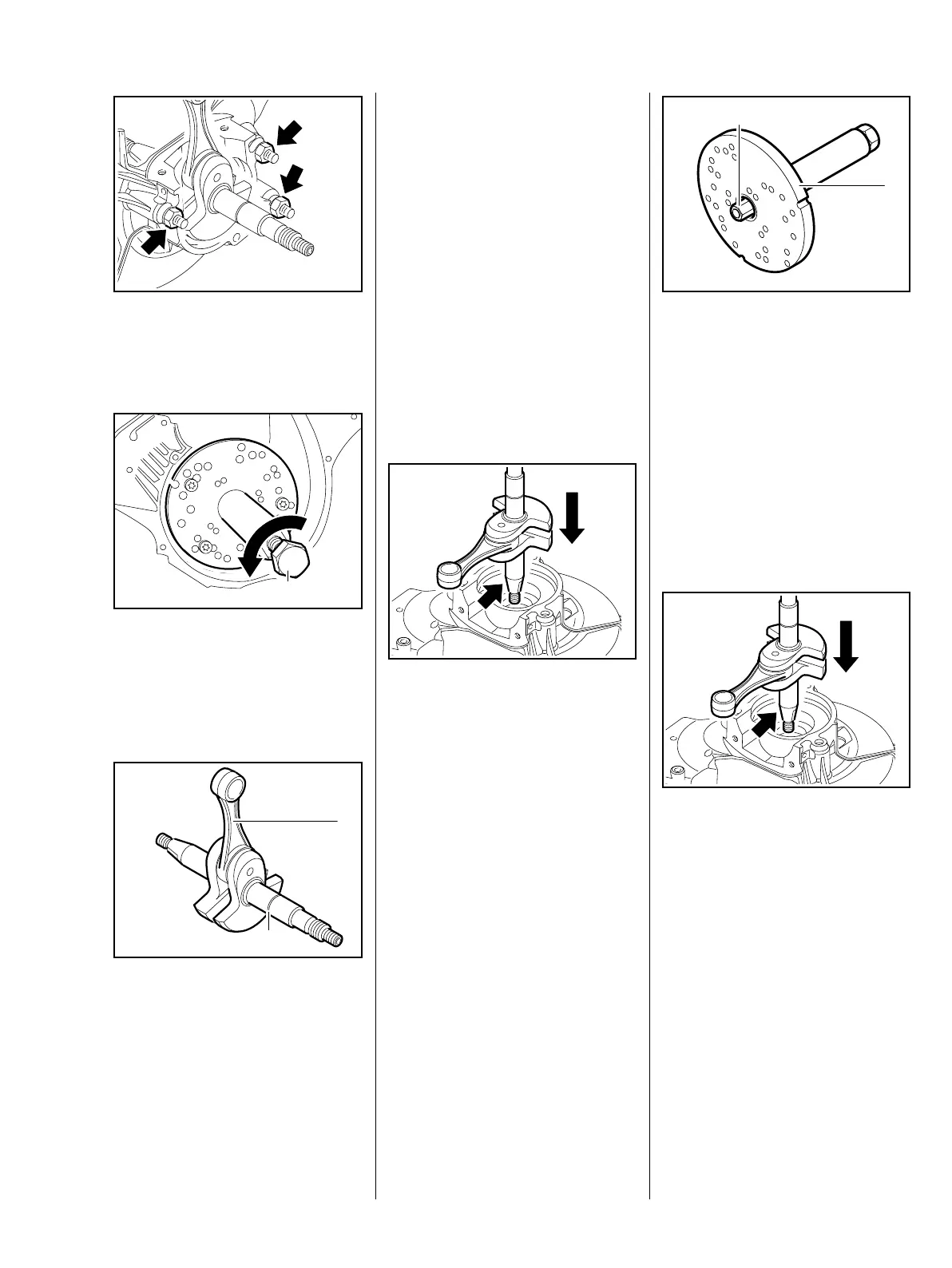

: Fit the screw sleeve (1)

5910 893 2421 as far as possible

over the fully retracted spindle of

the installing tool (2)

5910 893 2102.

Coat the conical crankshaft stub

with oil.

.

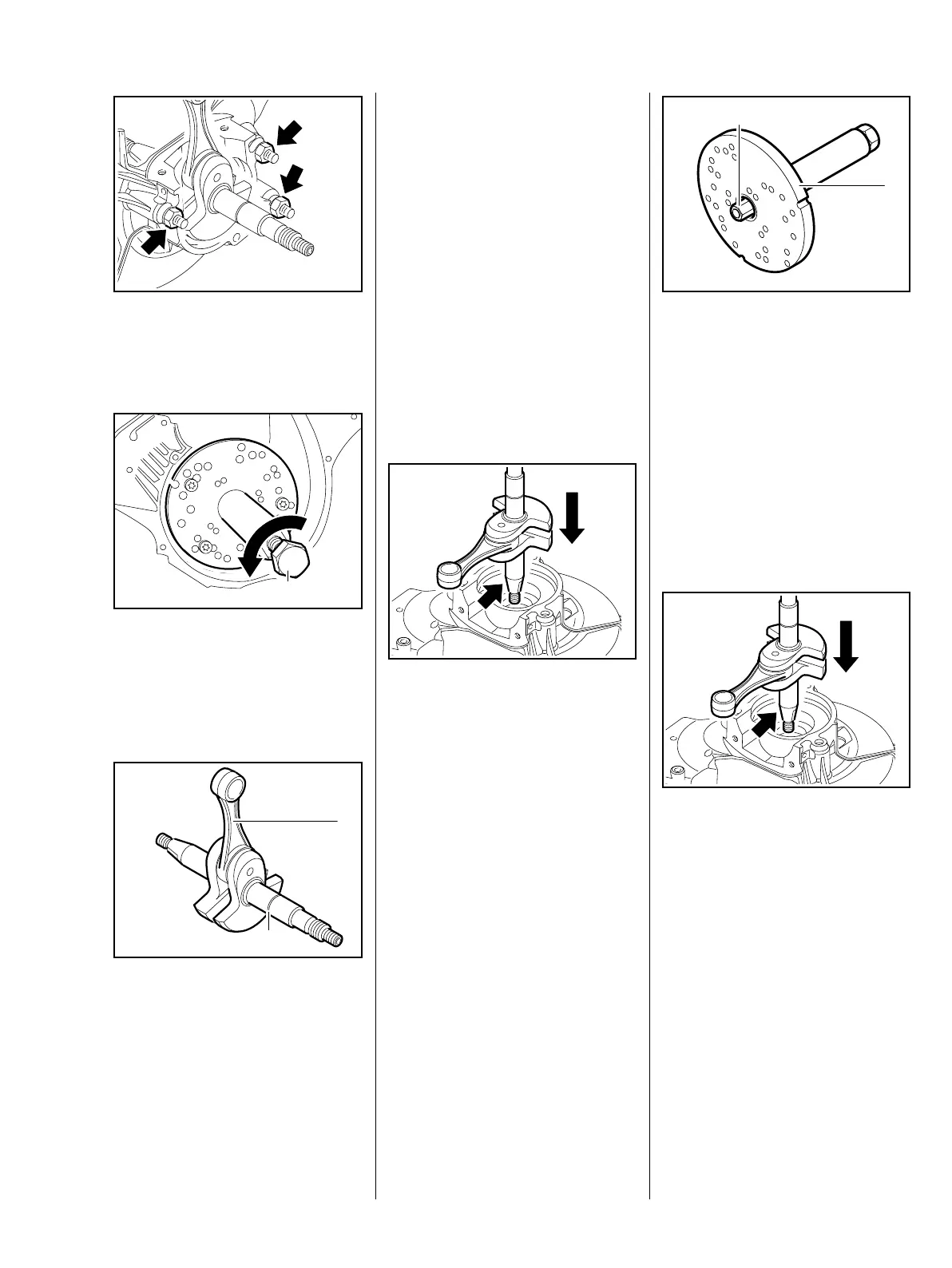

: Align the crankshaft with the

conical stub (arrow) facing the

ignition-side ball bearing and

push it home.

370RA146 TG

1

2

370RA145 TG

Loading...

Loading...