STULZ E

2

SERIES CONTROLLER FOR PERIMETER SYSTEMS OPERATION MANUAL

13

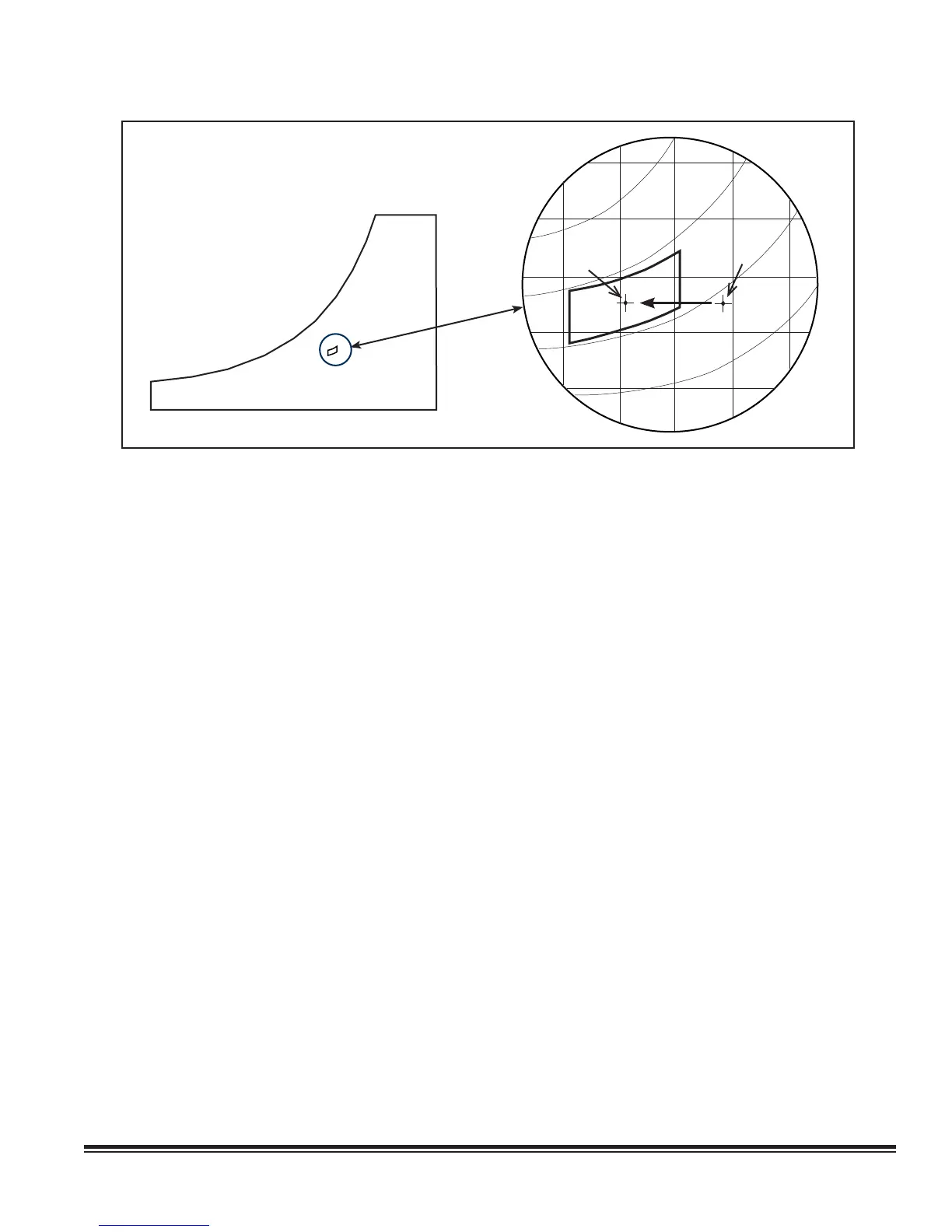

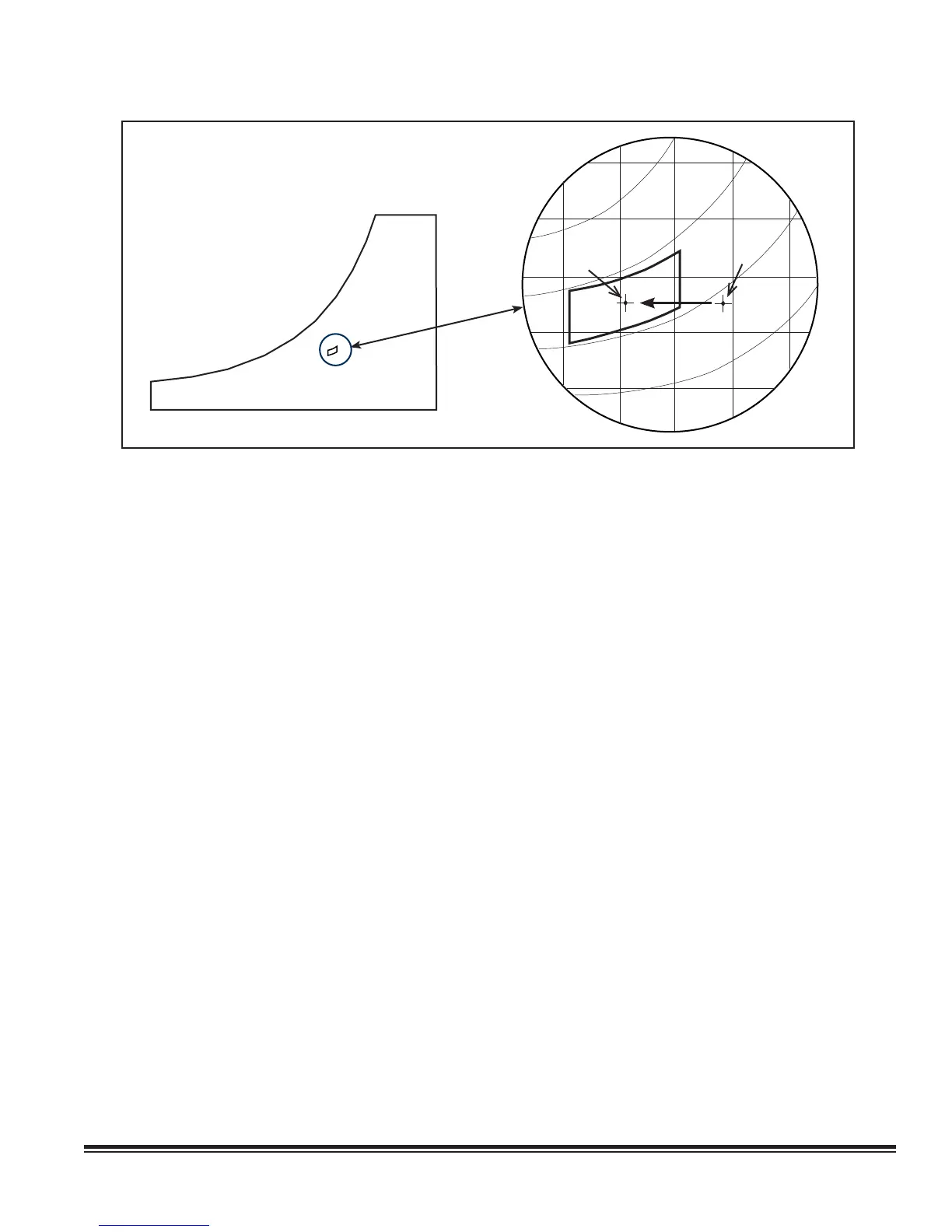

Cool Only- No

Humidifi cation

Needed

Actual

Temp/RH

(Dewpoint)

Setpoint

Psychrometric Chart

On dual compressor systems, equipped with a remote

condenser and enabled for hybrid control, the second stage of

cooling (compressor 2) is turned on when the measured

dewpoint is above the dewpoint cut-in setpoint for the second

stage. When the dewpoint drops below the cut-out setpoint

for the second stage, the second stage of cooling is turned off.

4.5 Operating Confi gurations

The operating confi guration for the controller depends on what

type of air conditioner is being controlled (i.e. AR, AHU, CW, W/G)

and what features are selected. The operating confi guration is

preset by the factory according to the application. If certain

features discussed in this manual are not factory enabled, no

screens for that feature will be shown.

4.5.1 Cooling

4.5.1.1 Chilled Water/AWS/FC

Upon a call for cooling, the controller activates a chilled

water control valve with a 010 VDC signal. The valve

opens proportionally to the demand for cooling based on

air temperature. The control settings consist of the return

temperature setpoint (in the Control>Set>Temperature

menu), the integration time (in Factory>Cool>Energy Savings

menu), and the CW Cut-in/Out offset and cooling band (in the

Service>COOL>CW1, AWS, FC menu). The chilled water

valve closes to the minimum position and remains at that

position when the return air temperature is less than the return

temperature setpoint plus the CW Cut-in/Out offset.

When the actual return air temperature rises above the return

air temperature setpoint plus the CW control cut-in value, the

CW valve position begins to increase proportionally from the

minimum position to the maximum, fully open position at the

return air temperature setpoint plus the cooling band. The

integration time allows the rate the valve position changes to

increase over a period of time as long as the difference between

the actual return air temperature is higher than the sum of the

return temperature setpoint plus the CW control cut-in and

cut-out offset (see Figure 6).

The starting voltage for the valve to be 0% open and ending

voltage for the valve to be 100% open varies, and is set in the

Confi guration level. For a valve that is fully closed at 2.5V and

fully open at 10V, the controller sends 2.5V to the valve when

0% opening is called for and ramps to 10V when the demand

increases to 100%.

For AWS and FC units the entering water temperature must

be colder than 55 °F (default value) for the unit to enter the

cooling mode and below 45 °F (default value) to enter the

dehumidifi cation mode. (This does not apply to CW systems.)

4.5.1.2 Compressor Based Direct Expansion (DX)

The controller cycles compressor(s) on and off for capacity

control when it is determined that a stage of cooling is called

for. A stage of cooling is turned on based upon the controller's

cooling response to temperature and humidity inputs from the

air sensors.

For systems with dual compressors, each cooling stage will turn

on following a time delay, once the programmed “Cooling Stage

Enable” setpoint value for that stage has been reached (see

Figure 6). When a compressor is turned on, it remains on until

the "minimum on" time has expired regardless of temperature

or humidity conditions. When a compressor is turned off, it

remains off until the "minimum off" time has expired regardless

of temperature or humidity conditions.

Figure 5. Dewpoint Control

Loading...

Loading...