STULZ E

2

SERIES CONTROLLER FOR PERIMETER SYSTEMS OPERATION MANUAL

14

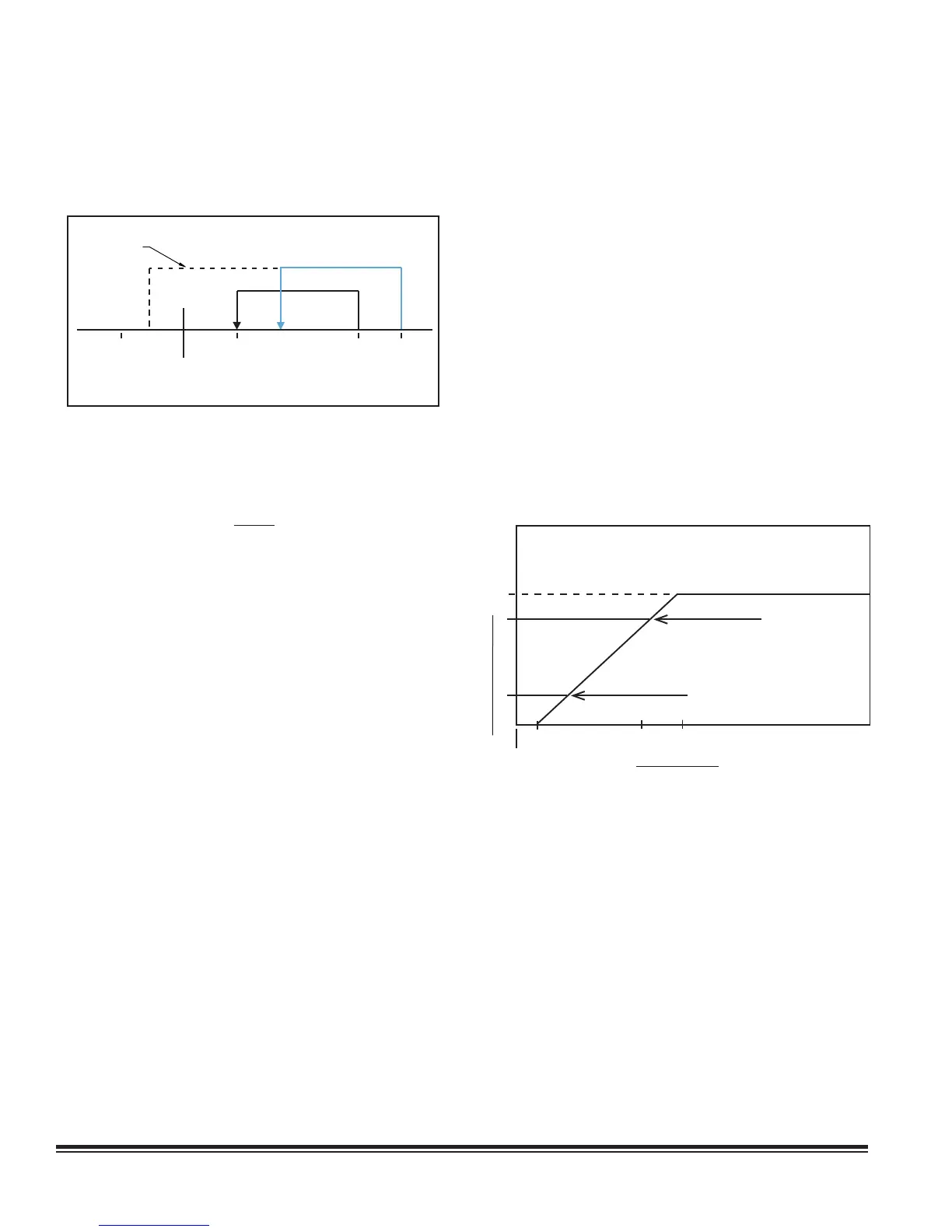

The compressor(s) are turned off in stages when the control

setpoint for each stage is achieved. To promote equal run

times, the controller is programmed in the Factory level menu

to rotate which compressor operates for the fi rst cooling stage

after each duty cycle.

Set

Point

Cut-in

1

Cut-in

2

Cut-out

1

Cut-out

2

Start

1

Start

2

Stop 1

Stop 2

Minimum

Run Time

Dehum

Min Temp

The cooling cut-in and cut-out setpoints should be set with a

minimum span of 2.0 °F.

NOTE

If the cooling cut-in/cut-out setpoints are set too

closely together when adjusting setpoints, the

compressor could run below the setpoint temperature

during periods of light heat loads because of the

minimum run time cycle.

4.5.1.2.1 Electronic Expansion Valve (EEV)

The controller may be programmed to manage the operation

of a EEV for each refrigeration circuit. The controller manages

the EEV based on input signals from suction pressure and

temperature sensors. The EEV maintains constant superheat at

the outlet of the evaporator by metering the fl ow of refrigerant

into the evaporator. By controlling superheat, the EEV keeps

nearly the entire evaporator surface active while preventing

liquid refrigerant from returning to the compressor. Adjustments

may be made by entering the Service>Sensors menu.

4.5.2 Energy Savings Confi gurations

There are several types of energy savings configurations

available: Economizer, Free-cooling (FC) and Alternate Water

Source (AWS). A W/G unit, where the condenser is cooled by a

liquid, can have an optional free cooling (FC) feature that takes

advantage of low temperatures of the W/G source. On AWS DX

(Alternate Water Source Direct Expansion) systems, there is a

separate W/G cooling coil that is used for cooling provided the

entering W/G temperature is low enough for it to be utilized.

4.5.2.1 Economizer

The economizer option enables the E

2

controller to minimize

or eliminate chilled water or compressor operation by utilizing

outside air when possible to satisfy temperature and humidity

demand and maintain the programmed setpoints. See Section

6.0 for an overview of economizer operation.

4.5.2.2 Alternate Water Source Cooling (AWS)

An AWS system (set at the Confi guration Level) utilizes an

independent chilled water source to provide coolant to an AWS

cooling coil which is located in the AC unit with the DX cooling

coil. When the Energy savings monitor option is set to “Yes”

in the Factory>Cool>Energy Savings menus, the entering

water temperature to the AWS coil is monitored and when that

temperature falls below the minimum value to use the AWS coil,

the AWS logic is enabled.

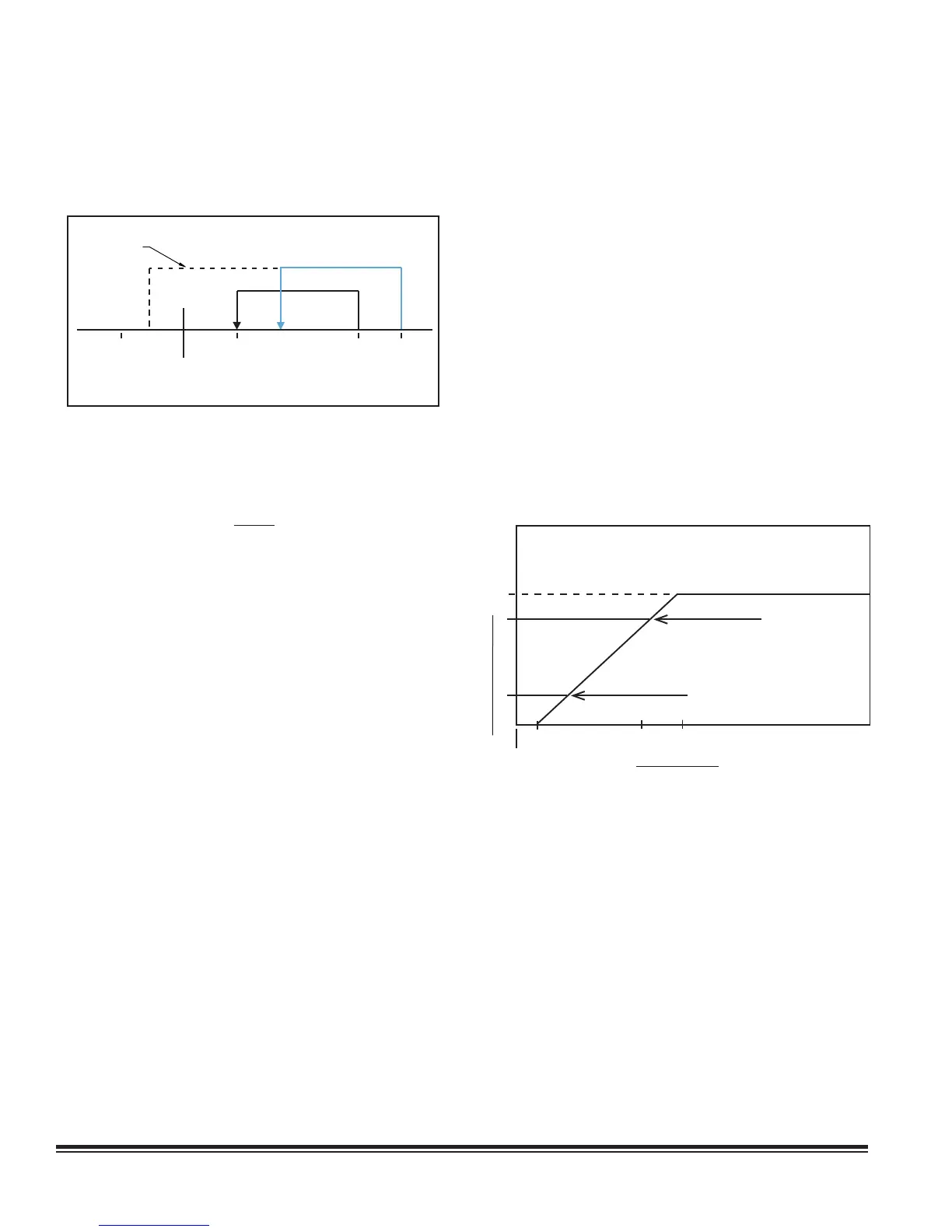

When the return temperature rises above the temperature

set point by the value set in Cut-out (0.3 °F by default), the

valve begins to open from the closed or 0% position. As the

temperature rises, the valve opens further in a manner that

makes it reach 100% open when the return temperature is at set

point plus the Band (20.0 °F by default) due to the proportional

component of the PID control of the CW valve. The Cut-out and

Band values are adjustable in the Service>Cool>CW,AWS,FC

menu.

Note that the actual voltage output to the valve for 0% and

100% are settable in the Factory>AnalogOut menu. The

defaults are 0.0 Volts for 0% and 10.0 volts for 100%.

0

Compressor on when valve

opens to this point

CW Valve Position

100%

Compressor off when valve

closes to this point

CW Valve Start

CW Valve

End

Setpoint

+CW cut-out

+Band

Temperature

The compressor assist works off of the valve position, thus it

is indirectly controlled by the return temperature, not directly.

When the valve opens due to the return temperature rising and

reaches the value set by CW Valve Start (100% by default) and

the time after reaching the CW Valve Start value has exceeded

the Start DX delay, the compressor is enabled. When the valve

closes due to the return temperature dropping and reaches the

value set by CW Valve End (10% by default), the compressor is

disabled. The CW Valve Start value does not have to be 100%;

it can be lowered to assist sooner in the CW valve stroke. If the

CW valve control has an integral component, it is best to leave

CW Valve Start value at 100% as the CW valve position will

increase over time to reach 100% if the return air temperature

remains constant above the Cut-Out value or continues to rise.

The CW Valve Start, Start DX delay and CW Valve End values

are adjustable in the Factory>Cool>Energy Savings menus.

There are three ways the AWS and DX circuits interact. These

Figure 6. Cooling On/Off Cycle

Figure 7. AWS/FC/DX Operation

Loading...

Loading...