STULZ E

2

SERIES CONTROLLER FOR PERIMETER SYSTEMS OPERATION MANUAL

18

transferred, it will not be allowed to re-start until the “minimum

compressor off” time delay period has elapsed. The A/C system

will operate using the alternate power source until the primary

power source is functionally restored.

When the primary power source is restored, the built-in timers

in the phase monitor relays delay the switch over to ensure the

power is actually stable before activating their output. After the

delay, operation of the A/C system is automatically transferred

back to the primary power source. The system controller must

again re-boot and restart the operating sequence as described

in the previous paragraph. The automatic power transfer time

from one power source to the other is factory set at 10 seconds.

The power transfer timers may be adjusted on the phase monitor

relays in the A/C system electric box. See STULZ addendum

OZU0005, "Operation of Automatic Transfer Switch"for details.

4.10.2 Power Transfer Performed by System

Controller

If the system controller is programmed to manage the dual

power transfer sequence, an optional Constant Contact UPS

module is provided (see Section 2.4.4). It keeps the controller

online while the power transfer sequence takes place. This

allows the controller to continue monitoring sensor input

signals and maintain communications with a BMS for up to one

minute. The controller will not have to reboot due to a power

interruption. It stays operational to indicate an alarm condition

and re-initiate the operating sequence after an automatic power

transfer occurs.

The system controller begins the start-up sequence after

approximately 10 seconds elapsed time which ensures the

“switch to” power source is stable. If the compressor and fans

were running at the time an automatic power transfer takes

place, they will restart as described in Section 3.3. When primary

power is restored, an automatic power transfer sequence occurs

again, returning the A/C system back to the primary power

source. The automatic power transfer delay time may be adjusted

using the system controller in the Service>Options>Dual Power

Setup menu screen (see Section 5.5.7.6).

4.11 Tandem Compressors Operation

The STULZ E

2

controller provided with the A/C unit may be

programmed to effi ciently manage the staging and rotation of

three compressors.

In the example of a system with three compressors, two small

compressors are paired together as one tandem circuit (1a

and 1b) with a shared liquid line and shared discharge line. The

compressor suction and discharge ports are equipped with

back pressure isolation valves so one compressor may operate

independently or both may operate together, as required by the

demand for capacity staging. One larger compressor is also

provided as circuit 2.

The STULZ E

2

controller manages operation of the three

compressors with a unique method of staging to conserve

energy by incrementally matching compressor capacity against

the load. The three compressors are turned on in various

combinations to provide a total of 4 stages of cooling. Each

stage is assigned an offset to the temperature setpoint for

turning the compressors on. The controller turns each stage

on and off as needed based on the temperature setpoint plus

offset values (reference Section 4.5.1.2).

The offsets for each stage may be adjusted in the Service>Cool

menu (see Section 5.5.1.1). The DX Cooling menu display

screens, discussed in Section 5.5.1.1 depict values relevant to

cooling stages rather than to individual compressors.

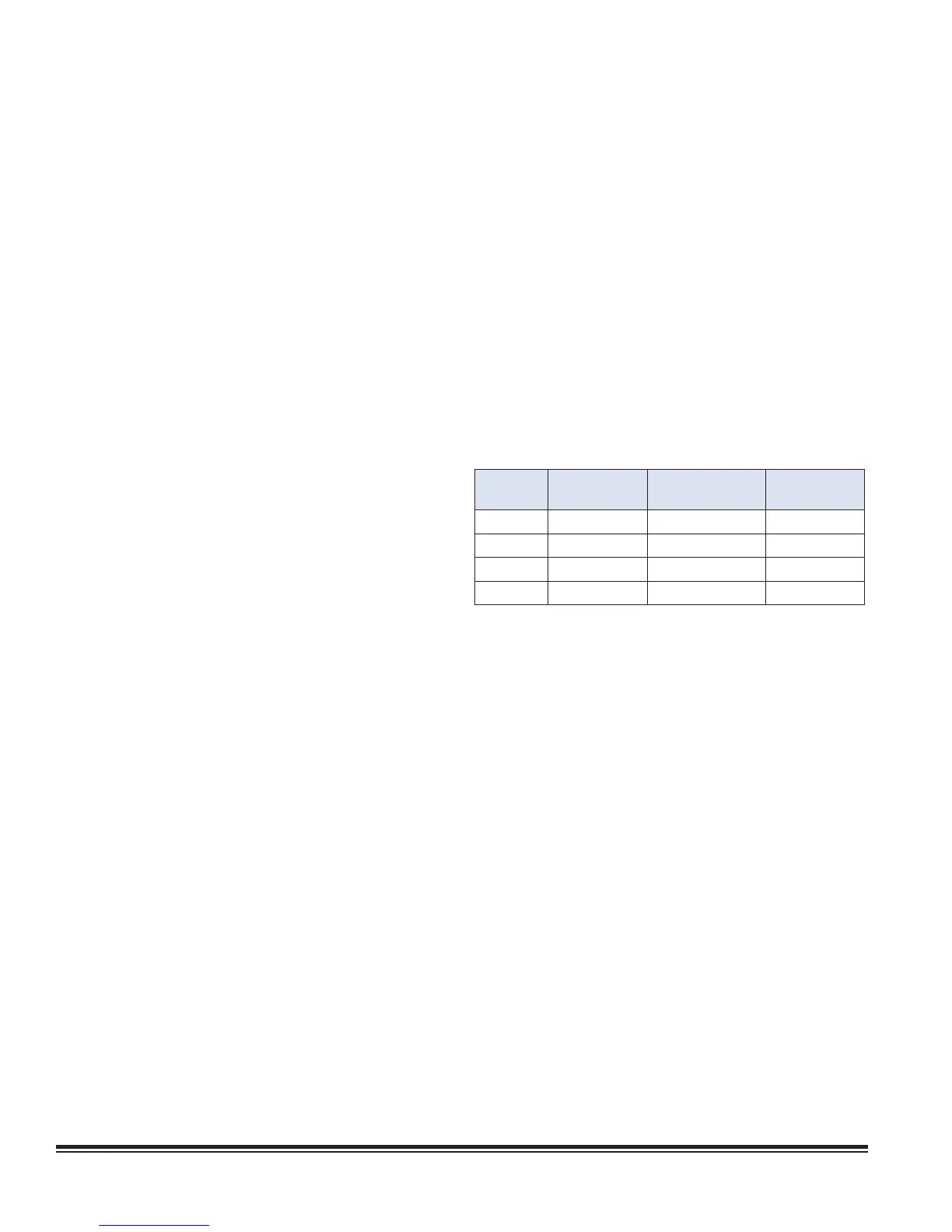

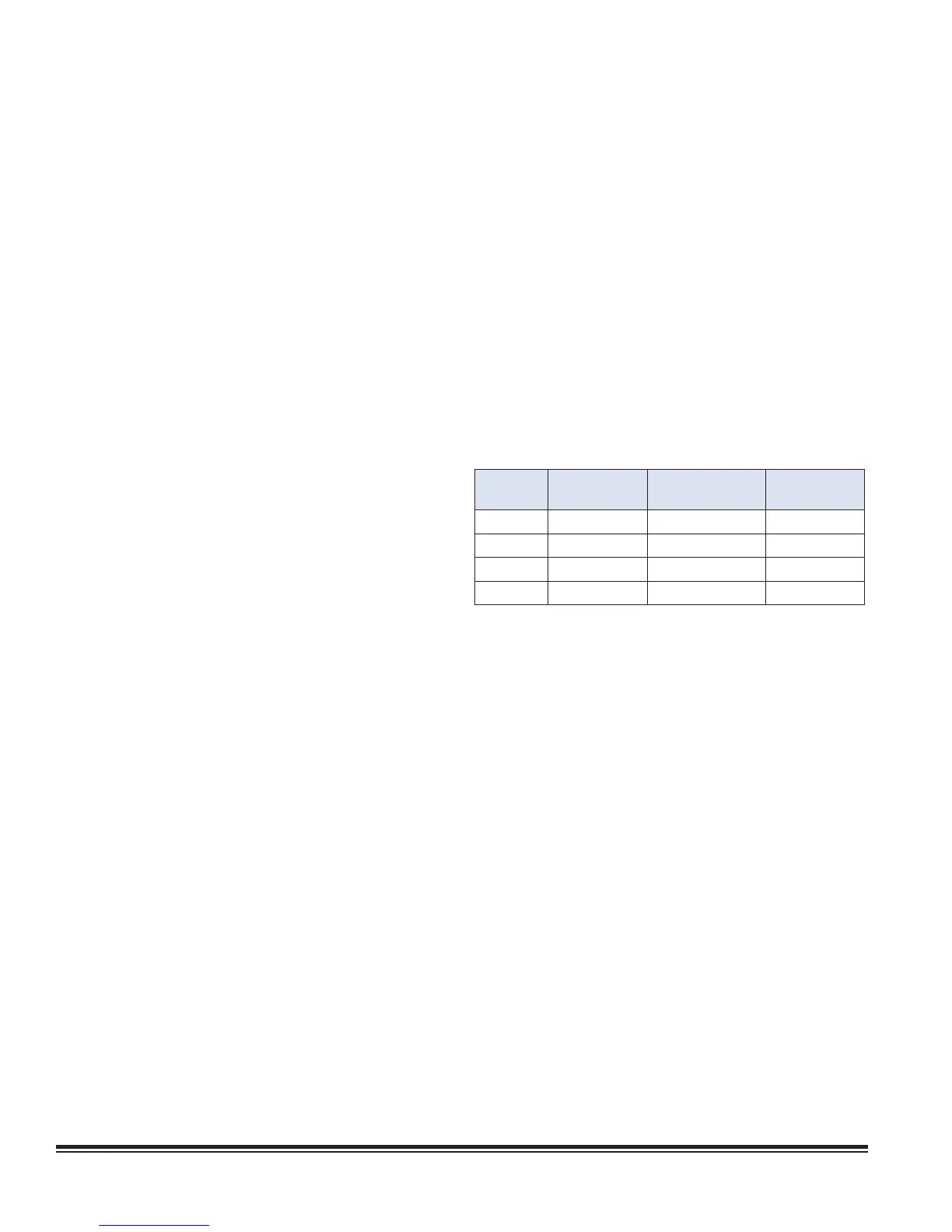

See Table 1 that follows. In the example of a 20 ton (240,000

BTU) system with three compressors, two small (5 ton)

compressors 1a and 1b are paired together as one tandem

circuit with a shared liquid line and shared discharge line.

One large (10 ton) compressor is also provided as circuit 2.

The following table shows how the compressors are staged

according to the capacity demand.

Stage

Cut-in Set-

point Offset

Compressor(s) Capacity

1 +2° F 1a 5 tons

2 +3° F 2 10 tons

3 +4° F 1b+2 15 tons

4 +5° F 1a+1b+2 20 tons

Table 1. Tandem Compressor Operation Example

4.12 Shadow Units

If the unit does not use an external EVD, the STULZ E

2

controller may be used to control up to three units as one with a

common display (set to pLAN address 1724). Shadow control

logic is used specifi cally for STULZ MCS systems which consist

of multiple STULZ CyberONE units integrated together to

operate as a multi-compressor cooling system. Refer to STULZ

Addendum #OCC0061 for detailed information.

The main unit controls the start and stop of the shadow units

and is in the pLAN address range of 18. The one or two shadow

units use pLAN addresses 916 to keep them out of the group

rotation logic. The shadow units follow the main unit in the

rotation process. The shadow units monitor the pLAN status of

the main unit to determine when to start and stop. They are “Off

by Network” when the main unit is not running due to conditions

such as waiting on a manual restart or other event like a BMS

pause. There is an option to allow the shadow units to run if they

see that the main unit is powered down, but the default is for

them to go to “Off by Network”.

The main unit does not normally monitor the shadow units

for starting and stopping, but it does monitor alarms coming

from the units. If the shadow unit is turned off manually or by a

critical alarm to then place it in manual restart mode, the main

unit continues to run and the shadow unit will not restart until

Loading...

Loading...