SummaCut Series Cutters User’ s Manual

General Information 1-23

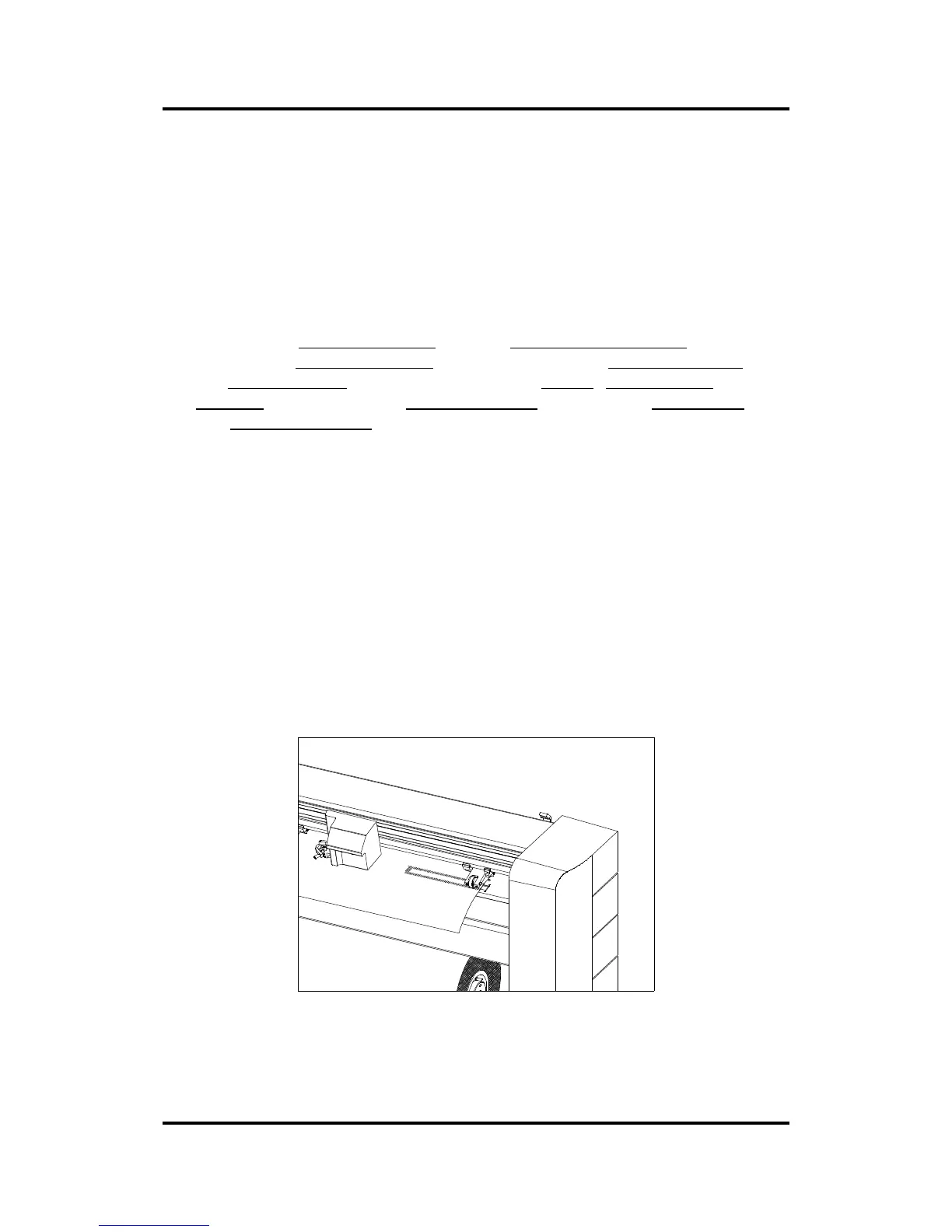

2b. When working with roll media and using the media support system at the

back of the machine, proceed by inserting a media flange at each end of

the media roll and tighten the thumbscrew until the media roll is firmly

gripped between the flanges. Make sure the flanges are firmly pressed

against the roll. Place the roll of media on the media support rollers at the

rear of the machine.

3. Start feeding the media from the rear of the machine until the front edge

of the media reaches the roll again at the front.

Position the left media edge on the left-most drive sleeve and check

whether the right media edge is positioned over the long drive sleeve. If so,

the left pinch roller can be positioned in a detent (click position) over the

left-most sleeve, and the right pinch roller is positioned somewhere over

the long drive sleeve to suit the media width. The pinch roller can be

lowered anywhere between the two detent (click positions) on the long

drive sleeve to allow for flexibility in holding any media width.

In circumstances where the above does not work, because your media is

too narrow to reach the long drive sleeve, try positioning the left media

edge over the second left drive sleeve, and position the right media edge

somewhere on the long drive sleeve.

4. To make sure that the media follows a straight path from the material roll

over the platen back to the roll, align the side edge of the media to the

roll, and make sure that the media is rolled up properly and follows a

straight path.

5. The pinch rollers should be positioned over the drive sleeves about 3 to 15

mm (0.1” to 0.6”) away from the media’ s outer edges.

FIGURE 1-10

PINCH ROLLER POSITIONING

Loading...

Loading...