getting started

112

Synrad Firestar f-Series operator’s manual

Mounting

f201/f400 mounting

Firestar f201/f400 mounting brackets are threaded to accept either metric or standard fasteners.

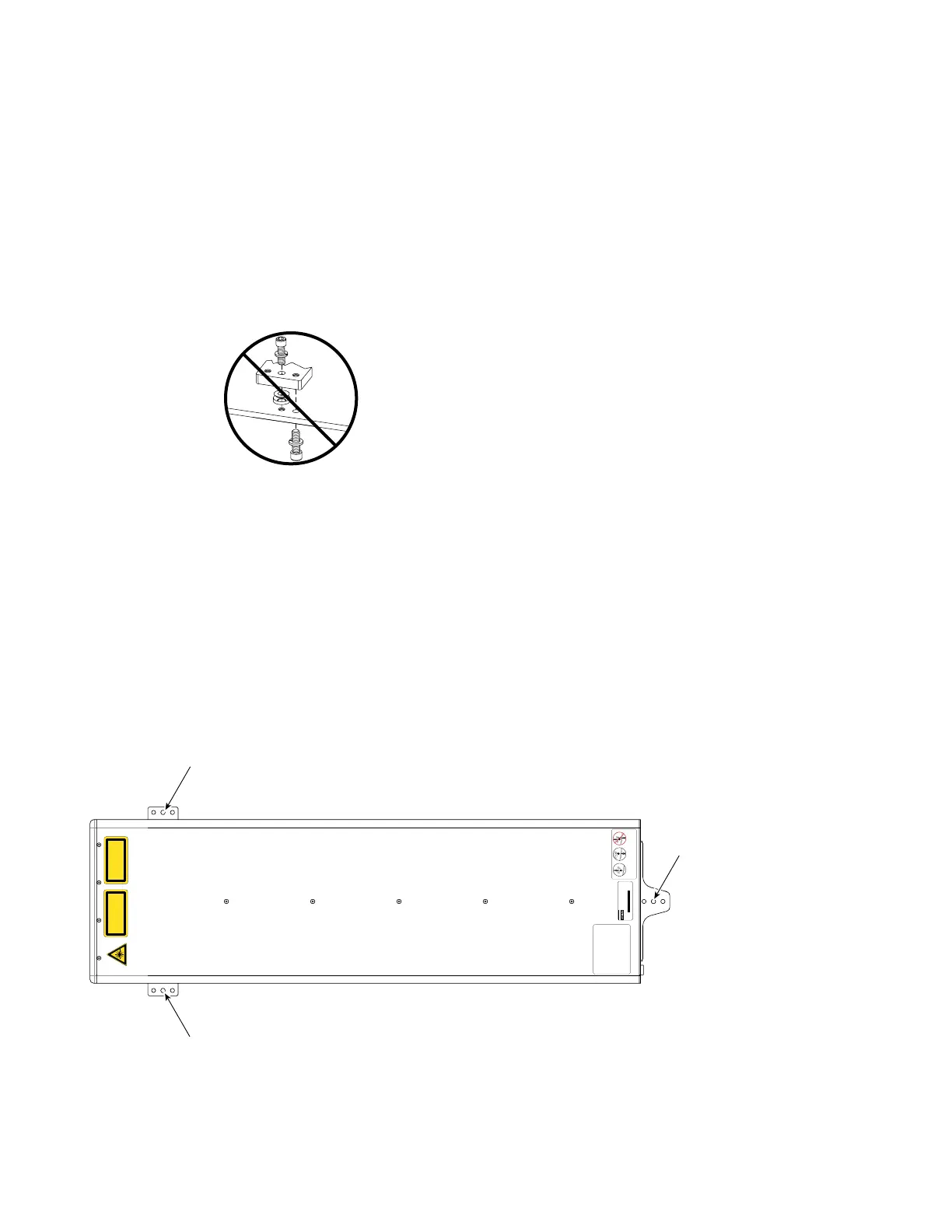

Important Note: As shown in Figure 1-7, DO NOT use more than one fastener per mounting loca-

tion. Using two or more fasteners per mounting tab will cause damage to the laser;

use only one fastener per location to mount your f201/f400 laser.

Figure 1-7 Improper mounting method

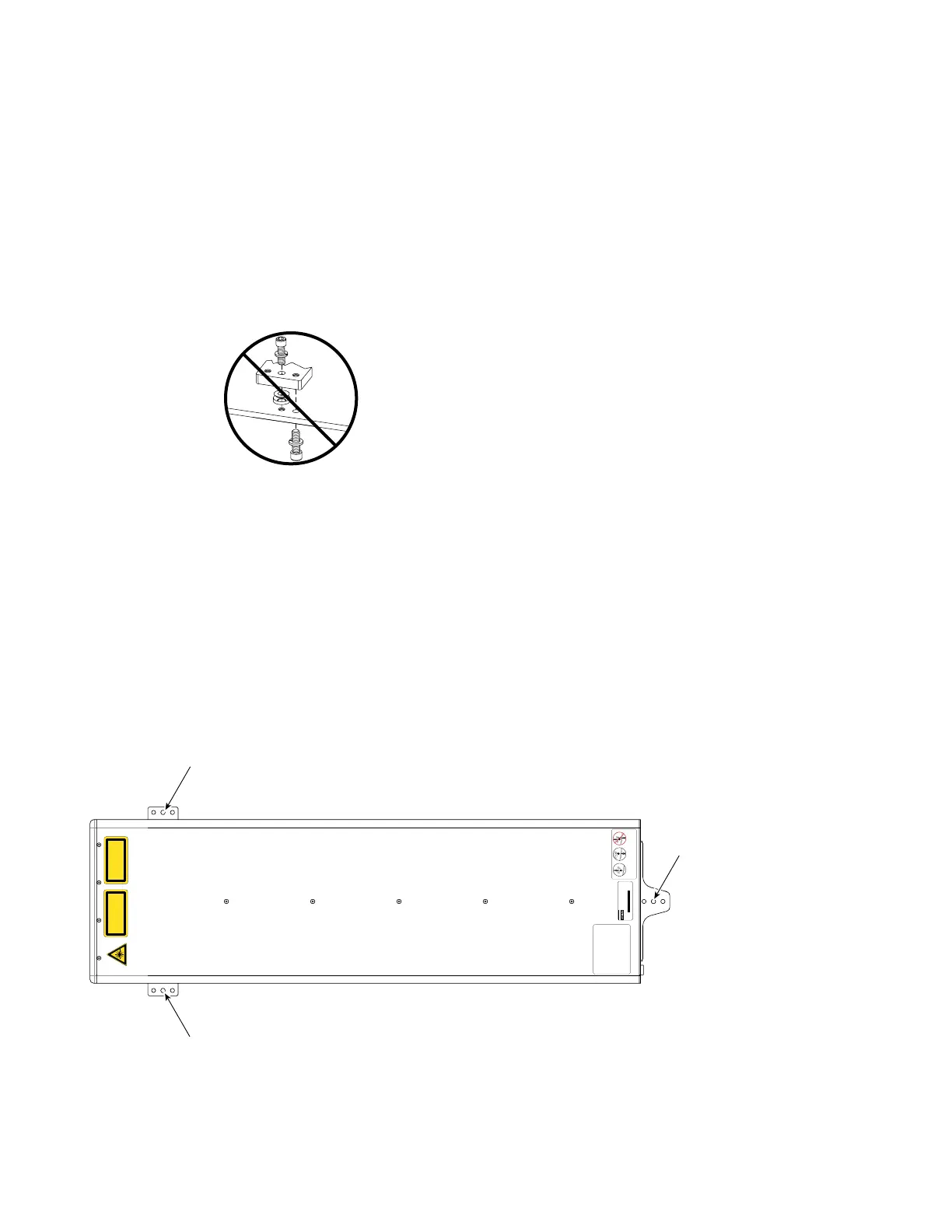

Fastening f201/f400 lasers from above

To fasten your f201/f400 laser to a mounting surface from above, perform the following steps:

1

Refer to the appropriate outline and mounting drawing for dimensions and then drill and tap three

M8 × 1.25 (f201) or M10 × 1.5 (f400) holes into your mounting surface. For SAE installations, drill

and tap three 5/16–18 (f201) or 3/8–16 (f400) holes into your mounting surface.

These hole locations (referenced by Note 2 on the O & M drawings) should correspond to the thru

holes labeled “A” as shown in Figure 1-8.

Figure 1-8 Fastening f201/f400 from above

2

Assemble three spherical washer sets as detailed in the Outline and Mounting drawing.

3

Place the spherical washer sets over the threaded holes in your mounting surface.

Do not use more than

one fastener per mount

ing foot. Doing so will

damage the laser

INVISIBLE LASER RADI A TIO N

A V OID EYE OR SKIN EXPOSURE T O

DIRECT OR SC A TTERED RADI A TIO N

CLASS 4 LASER P R ODUC T

EN-60825-1, 2007

1400 W A TTS MA X

10200-10800 NANOMETERS

C A UTION

CONDENS A TION AN D

W A TER D AM A GE CA N

OCCUR IF COOLING W A TE R

IS BEL O W DEW POIN T .

SEE OPER A TION MAN U AL .

Insert metric or UNC

fastener thru laser

mount and spherical

washer set into threaded

mounting plate

Insert metric or UNC

fastener thru mounting

plate and spherical washer

set into threaded metric

or UNC hole in laser mount

Do not use more than

one fastener per mount-

ing foot. Doing so will

damage the laser

OR

The RF Drive circuit in this laser is designed to

sense fault conditions that could potentially

damage the laser’s electronic circuit boards.

On rare occasions, the laser may shutdown during

the start-up sequence. When this happens, the

Ready indicator will flash a series of three blinks,

pause, and then repeat. If this occurs, remove DC

power from the laser, wait 30 seconds, and then

re-apply DC power.

If the Ready indicator continues to flash, contact

SYNRAD, Inc. as this may indicate a serious

problem in the laser’s control circuit.

MODEL #: FSF400SD

SERIAL #: F400204082943

TESTED AT: 96V MFG: July 22, 2008

This laser component does not comply with standards for complete

laser products as specified by 21 CFR 1040.10 or IEC 60825-1.

SYNRAD, Inc. 4600 Campus Place, Mukilteo WA 98275 425.349.3500

Top View

(f400 model shown)

Cooling fittings

removed for clarity

Loading...

Loading...