technical reference

35

Synrad Firestar f-Series operator’s manual

Technical overview

Focusing optics

When selecting a focusing optic, the primary consideration should be material thickness and any vertical

tolerances that occur during nal part positioning rather than making a selection based only on minimum

spot size. The chosen focal length should create the smallest possible focused spot while providing the

depth of eld required for the material to be processed.

Caution

possible

equipment

damage

Trace amounts of contamination on the laser’s output window (or

on any optic in the beam path) can absorb enough energy to damage

the optic. Inspect all beam delivery optics periodically for signs of

contaminants and carefully clean as required. In dirty environments,

purge laser optics using ltered air or nitrogen to prevent vapor and

debris from accumulating on optical surfaces.

Optics are fragile and must be handled carefully, preferably by the mounting ring only. Be careful to select

optics that are thick enough to withstand the maximum assist gas pressure available for the process. This

is especially important in metal cutting applications using high-pressure assist gases. Cleanliness is another

important issue aecting performance and becomes increasingly important as laser power increases. Dirty

or scratched lenses will under perform, exhibit a vastly shortened lifetime, and may fail catastrophically.

When the laser application requires air as an assist gas, use only breathing quality air available in cylinders

from a welding supply company. Compressed shop air contains minute particles of oil and other contami-

nants that will damage optical surfaces. If compressed shop air is the only choice available, it must be

ltered to the specications shown in Table 3-1.

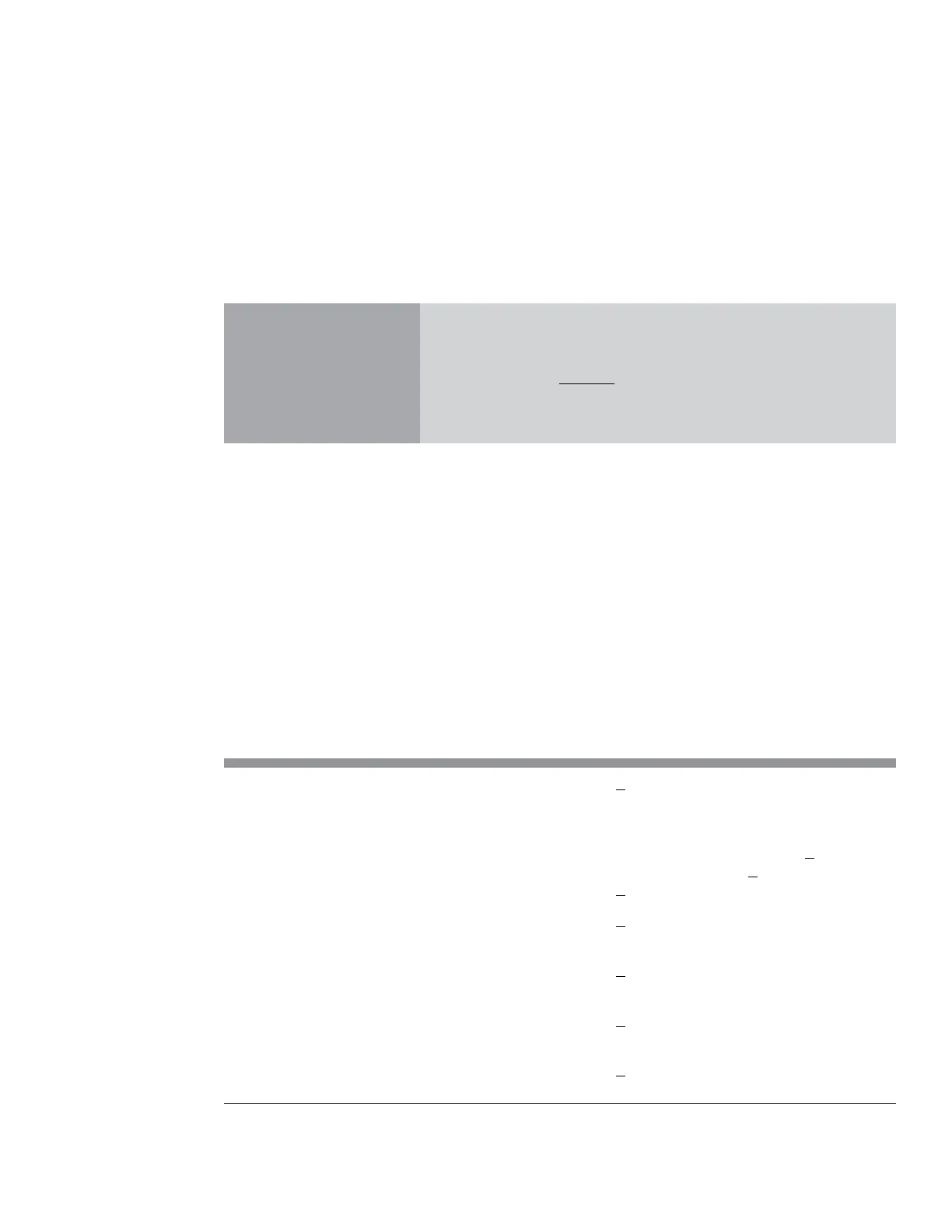

Table 3-1 Assist gas purity specications

Assist Gas Typical Purpose Specication

Air Cutting/Drilling Breathing Grade > 99.9996% purity; ltered to ISO Class 1

particulate level

Air Cutting/Drilling Compressed Instrument-grade air ltered and dried to

ISO 8573-1:2010 Class 1, 2, 1 (< 10 1.0–

5.0 µm particles/m

3

; < –40 °F dew point;

< 0.01 mg/m

3

oil vapor)

Argon Welding High Purity Grade > 99.998% purity; ltered to ISO Class 1

particulate level

Helium Welding High Purity Grade > 99.997% purity; ltered to ISO Class 1

particulate level

Nitrogen Cutting/Drilling High Purity Grade > 99.9500% purity; ltered to ISO Class 1

particulate level

Oxygen Cutting/Drilling Ultra Pure Grade > 99.9998% purity; ltered to ISO Class 1

particulate level

Loading...

Loading...