getting started

118

Synrad Firestar f-Series operator’s manual

Caution

possible

equipment

damage

Do not remove or replace the threaded coolant ttings on the rear of

the laser. This can lead to internal leaks, and in some cases, misalign-

ment of the laser. To convert the standard tubing ttings to metric,

please use the 1/2-inch to 12-mm tubing adaptors supplied in the

laser’s ship kit.

Caution

possible

equipment

damage

Inlet cooling water temperature must always be maintained above the

dew point to prevent condensation and water damage to your Firestar

laser.

Connecting

f100/f201 cooling tubing connections

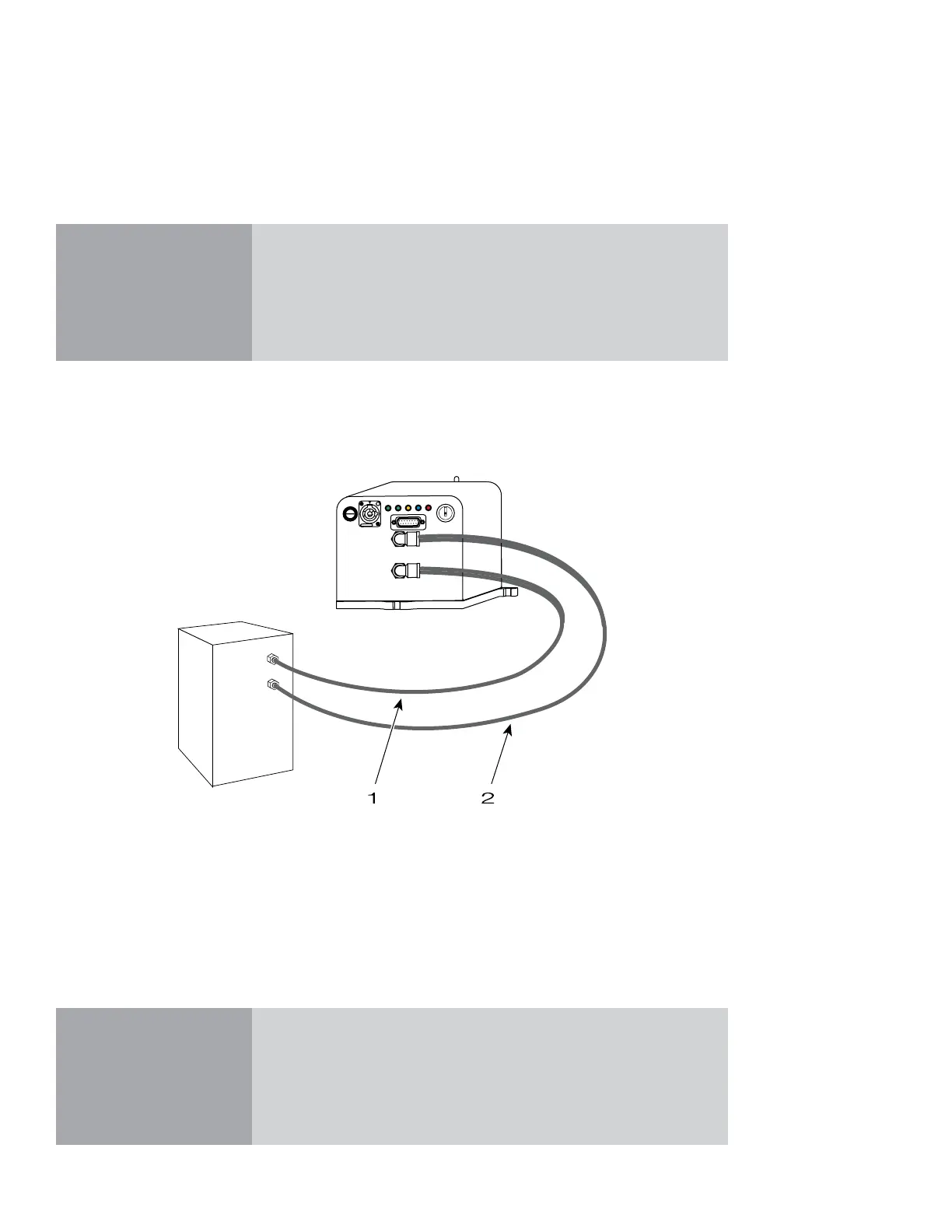

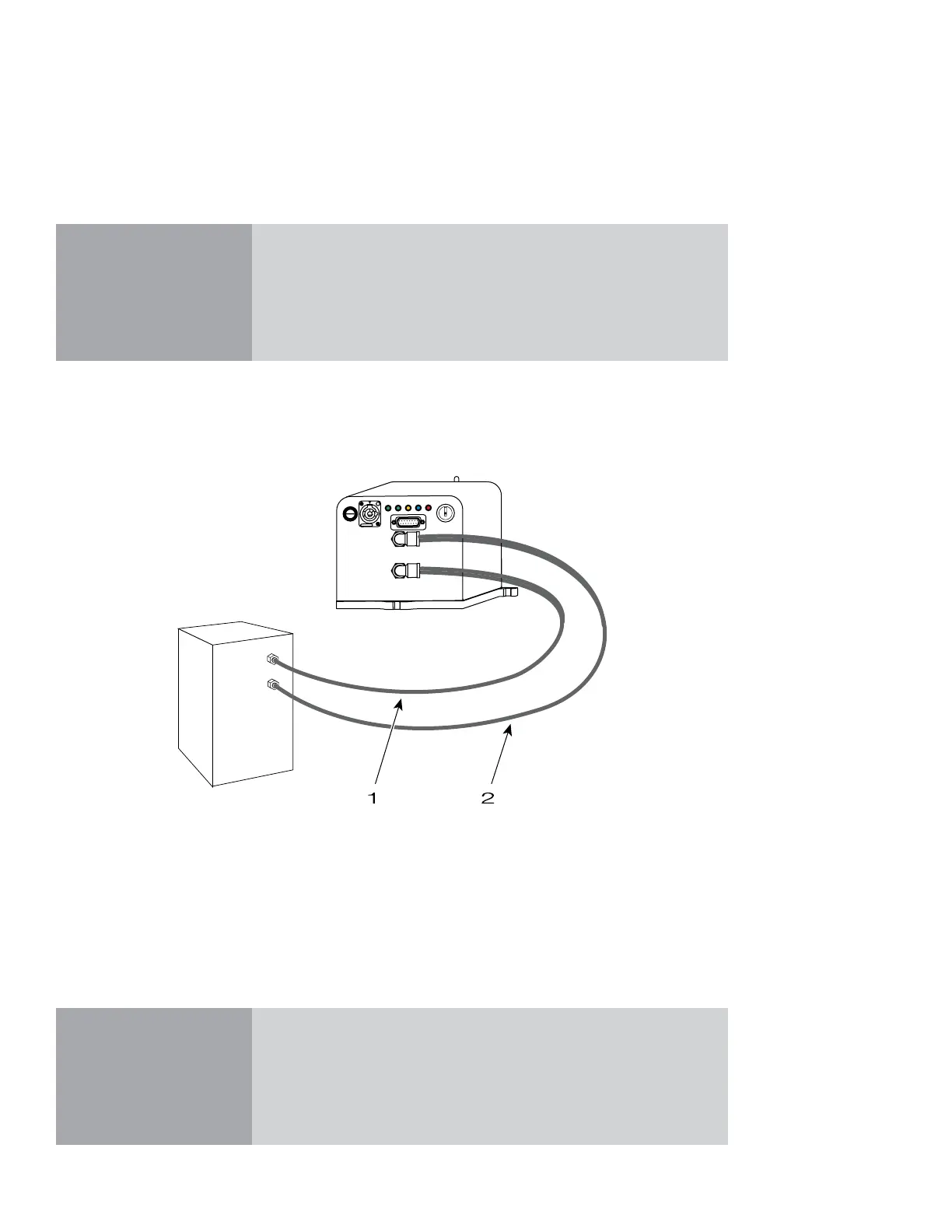

To connect cooling tubing to your f100 or f201 laser, refer to Figure 1-12 and perform the following steps.

The numbered items in Figure 1-12 correspond to the step numbers in the following procedure.

Figure 1-12 Firestar f100/f201 cooling connections

1

Cut and connect a length of cooling tubing to t between the chiller’s Outlet port and the

WATER IN port on the rear of your f100/f201 laser.

2

Cut and connect a length of cooling tubing to t between the WATER OUT port on the rear of the

laser and the chiller’s Inlet port.

OUTLET

INLET

Chiller

WATER IN

WATER OUT

USER I/O

DC POWER

96 VDC 18A MAX

20A FAST

FUSE

ON

OFF/RESET

Lase

Shutter

Ready

Temp

Remote

Interlock

Loading...

Loading...