getting started

114

Synrad Firestar f-Series operator’s manual

Mounting

2

Assemble three spherical washer sets as detailed in the outline and mounting drawing.

3

Place the spherical washer sets over the thru holes in your mounting surface.

4

Carefully position the laser so that each threaded hole in the baseplate (labeled “M” or “S” in Figure

1-10) aligns with a spherical washer and thru hole in the mounting surface.

5

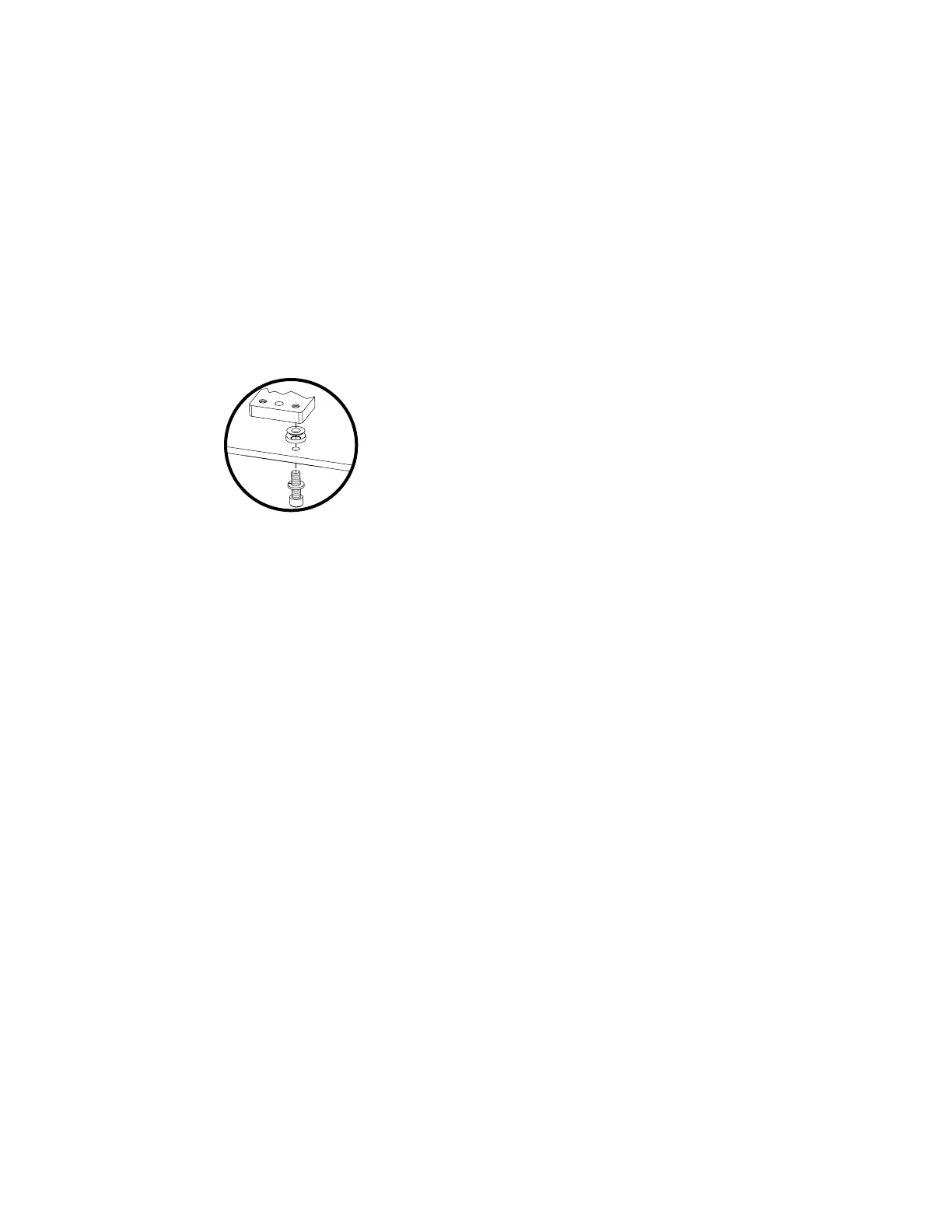

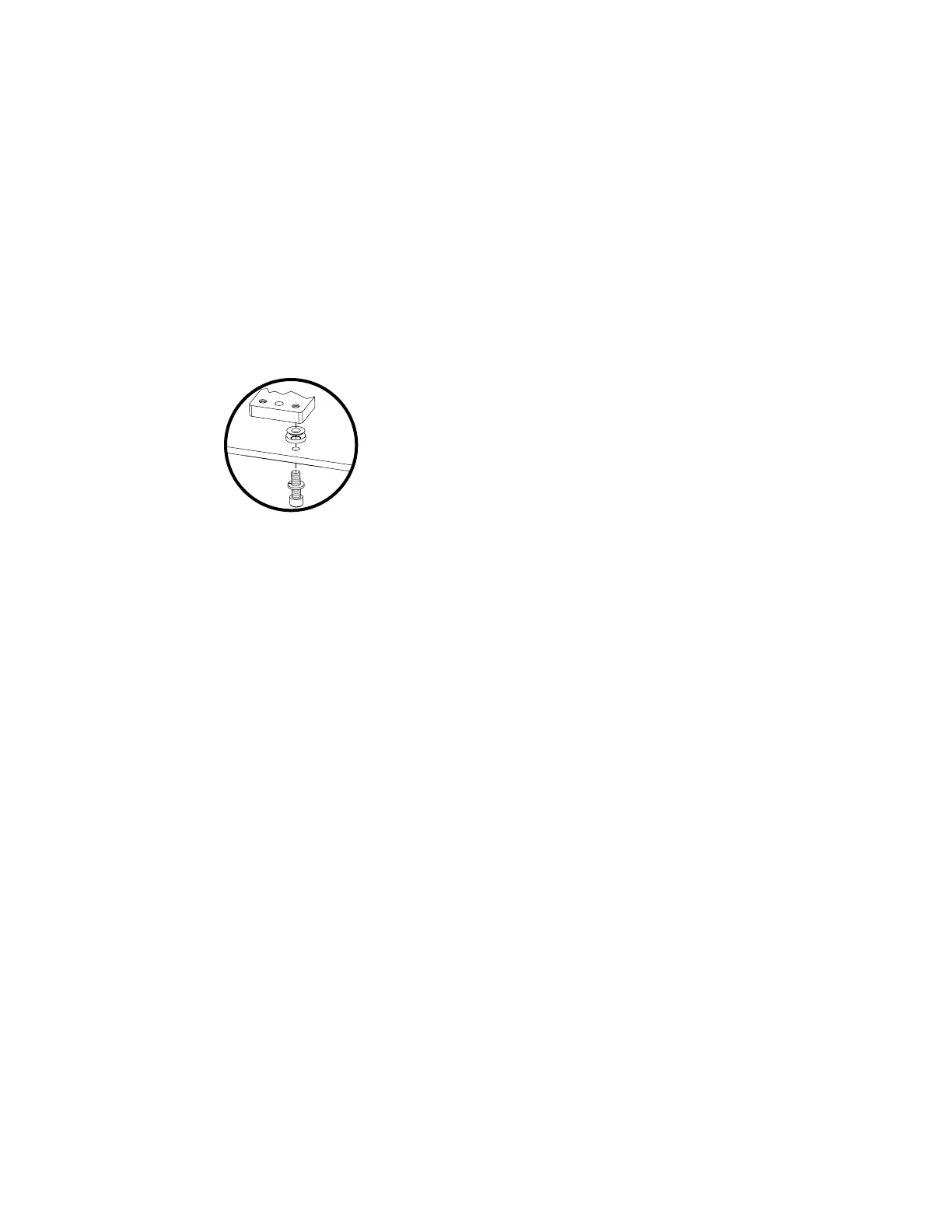

Insert the appropriate metric or standard capscrews, included in the laser’s ship kit, through the

mounting surface and spherical washers into the threaded holes of Firestar’s baseplate (see Figure

1-11). Turn the screws by hand until the threads engage.

Figure 1-11 Detail of fastening into laser

6

Evenly tighten all three capscrews. For M8 capscrews, torque to 12 N m; for M10 capscrews, tighten

to 24 N m. When using 5/16" capscrews, torque to a value of 13 ft lb; for 3/8" capscrews, tighten to

23 ft lb.

Insert metric or SAE

fastener thru mounting

plate and spherical washer

set into threaded metric

or SAE hole in laser mount

Loading...

Loading...