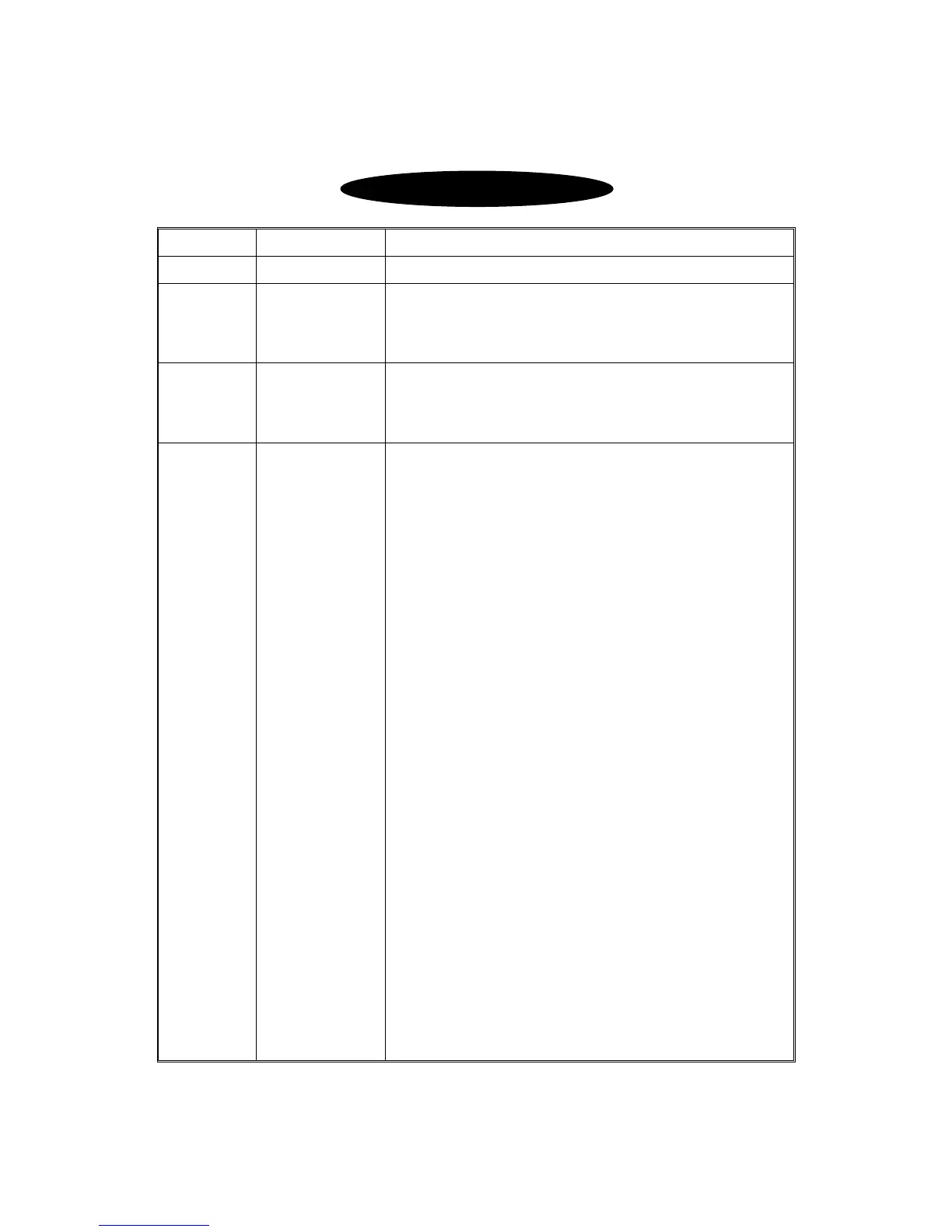

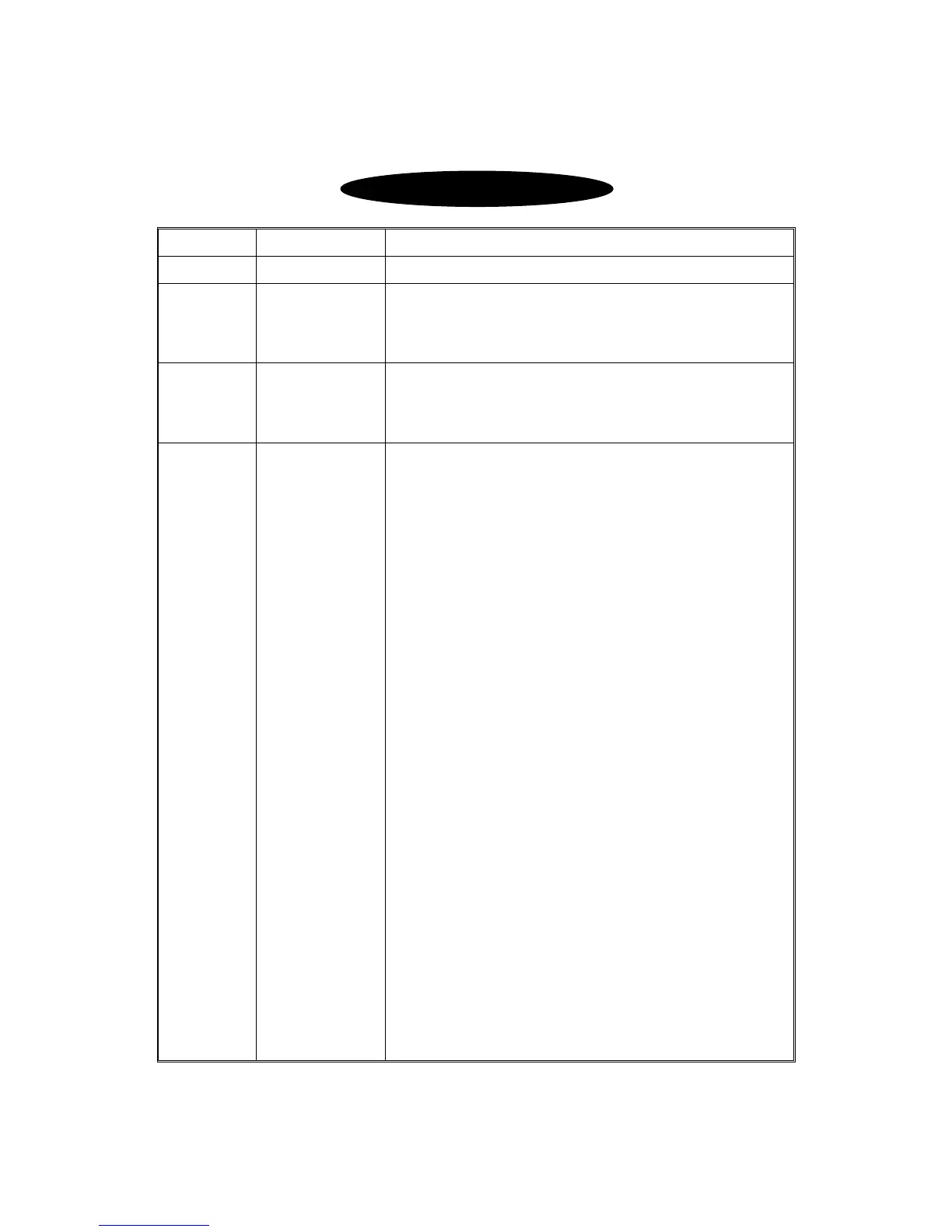

Revision History

Date Code Revision history

2002.7. 10310000380 First edition is published

2003.5. 10310000380 A revised edition is published

– Main unit and expansion modules are added

– Built-in function are upgraded

2003.9 10310000380 A revised edition is published.

- Main units are added

- Built-in functions are upgraded.

Loading...

Loading...