3-8

3

CONTROL VALVE

FUNCTION

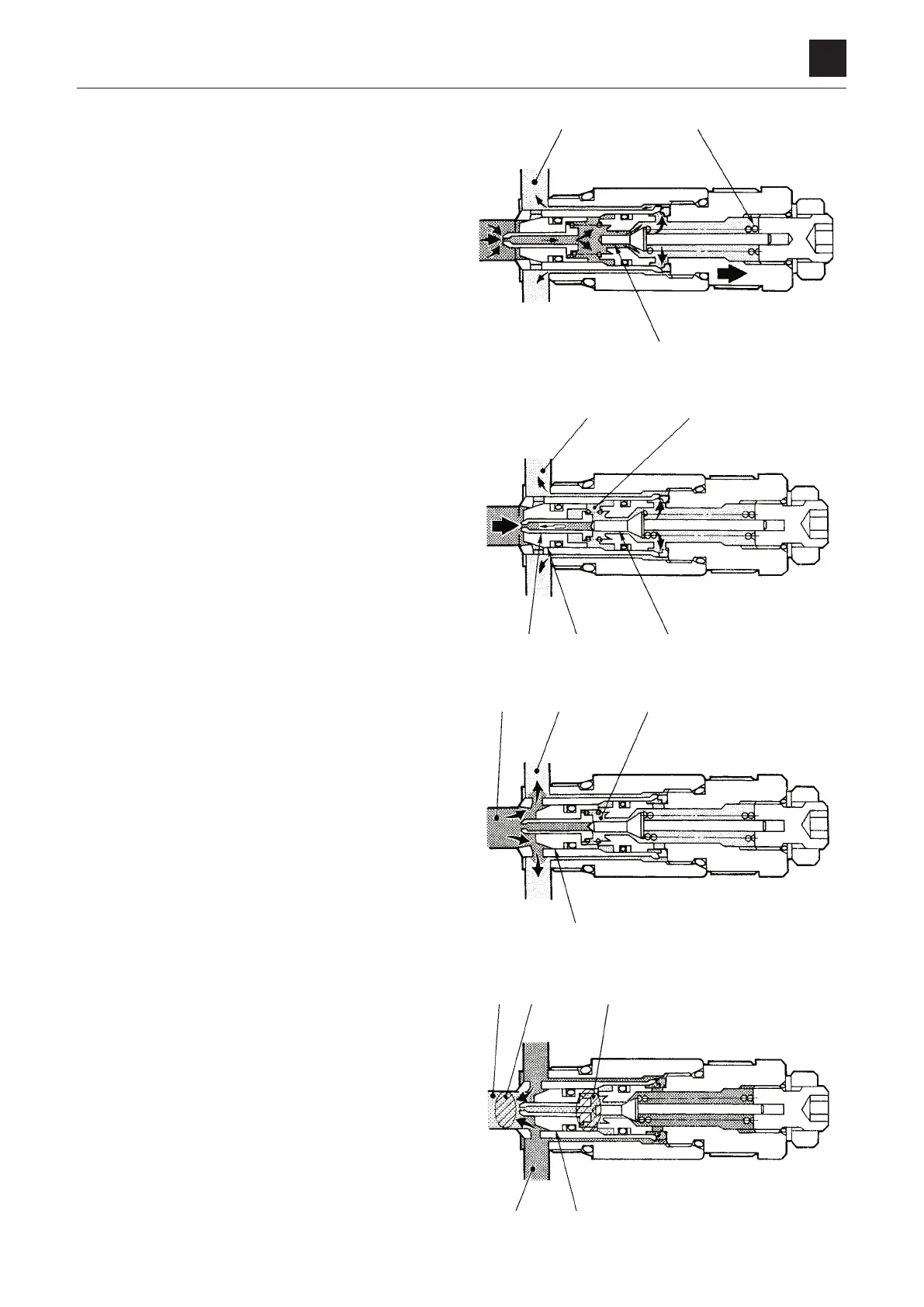

If the pressure in the circuit becomes higher than the force

of the spring (7), the needle valve (5) is pushed to the right

by hydraulic pressure, connecting the high-pressure area

with the tank passage T. The oil then flows around the cir-

cumfer

ence of the needle valve (5) and passes through the

slits, flowing into the tank passage T.

When the needle valve (5) is pushed to the right to con-

nect

the high-pressure area with the tank passage T, the

pressure on the back side of the piston (4) drops and the

piston (4) is pushed to the right against the needle valve

(5).This shuts off the flow of hydraulic oil flowing from the

chamber B to the chamber C, resulting in a low pressure in

the chamber C.

If

the pressure of the chamber C becomes lower than that

of the chamber B, equilibrium cannot be maintained. As a

result, the main poppet (6) opens to allow the hydraulic oil

to flow into the tank passage T.

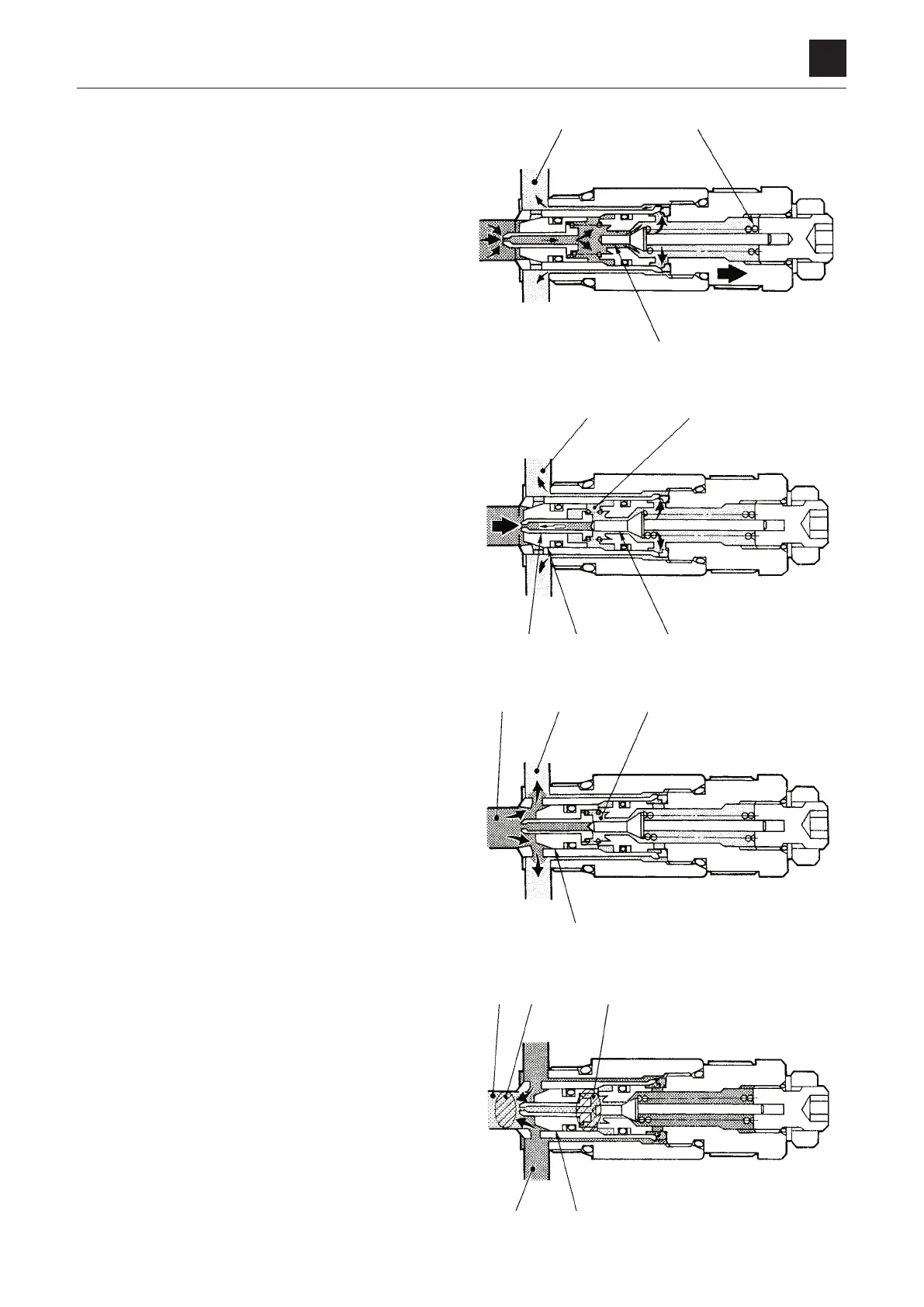

Suction operation:

If

the cylinder is operated at a speed too fast for the oil

supply to keep up, and thus the pressure of the chamber B

becomes almost negative, the oil from the tank is supplied

to prevent cavitation.

When the pressure in chamber B is lower than the pressure

in the tank passage T, the difference in the sectional areas

of A and A1 causes the main poppet (6) to open. Then,

oil to fill the space in the chamber B enters from the tank

passage T.

Loading...

Loading...