4-142

4

CYLINDERS

DISASSEMBLY AND ASSEMBLY

Inspection and adjustment

Inspection after disassembly

Clean each part thoroughly with cleaning oil, then carry out

the following checks. When a cylinder has been disassem-

bled, r

eplace all the seals with new ones.

1. Piston rod

• Replace the rod if there are cracks.

• If the threads are damaged, repair them or replace

the rod.

• If the plating layer of the plated portion is broken,

rusted or scratched, replace the rod.

• If the rod is bent more than the limit of 1 mm in 1 m,

replace it. (For the measurement method, refer to

the figure on the right.)

• If the inner diameter of the clevis bushing is worn,

replace the bushing.

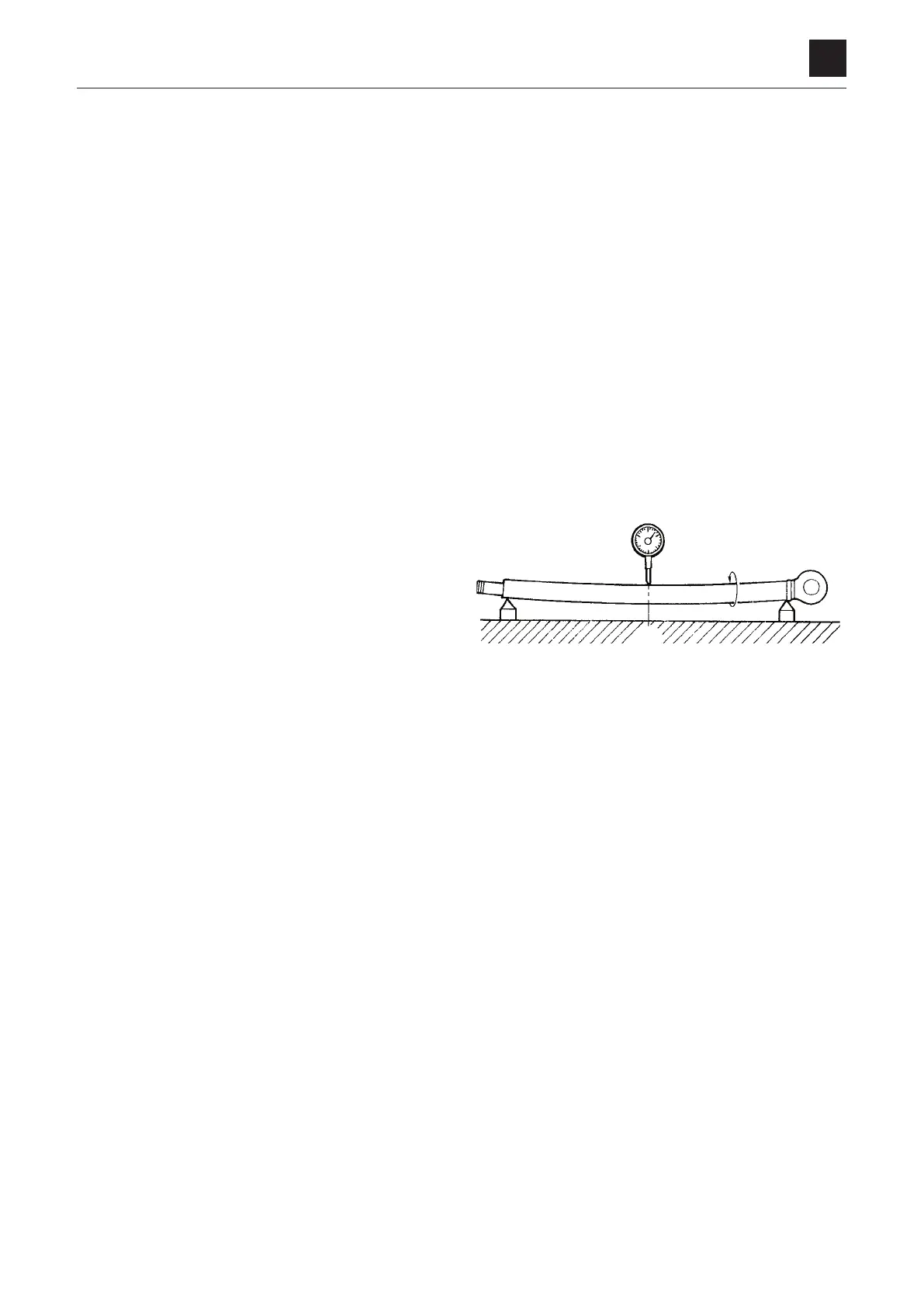

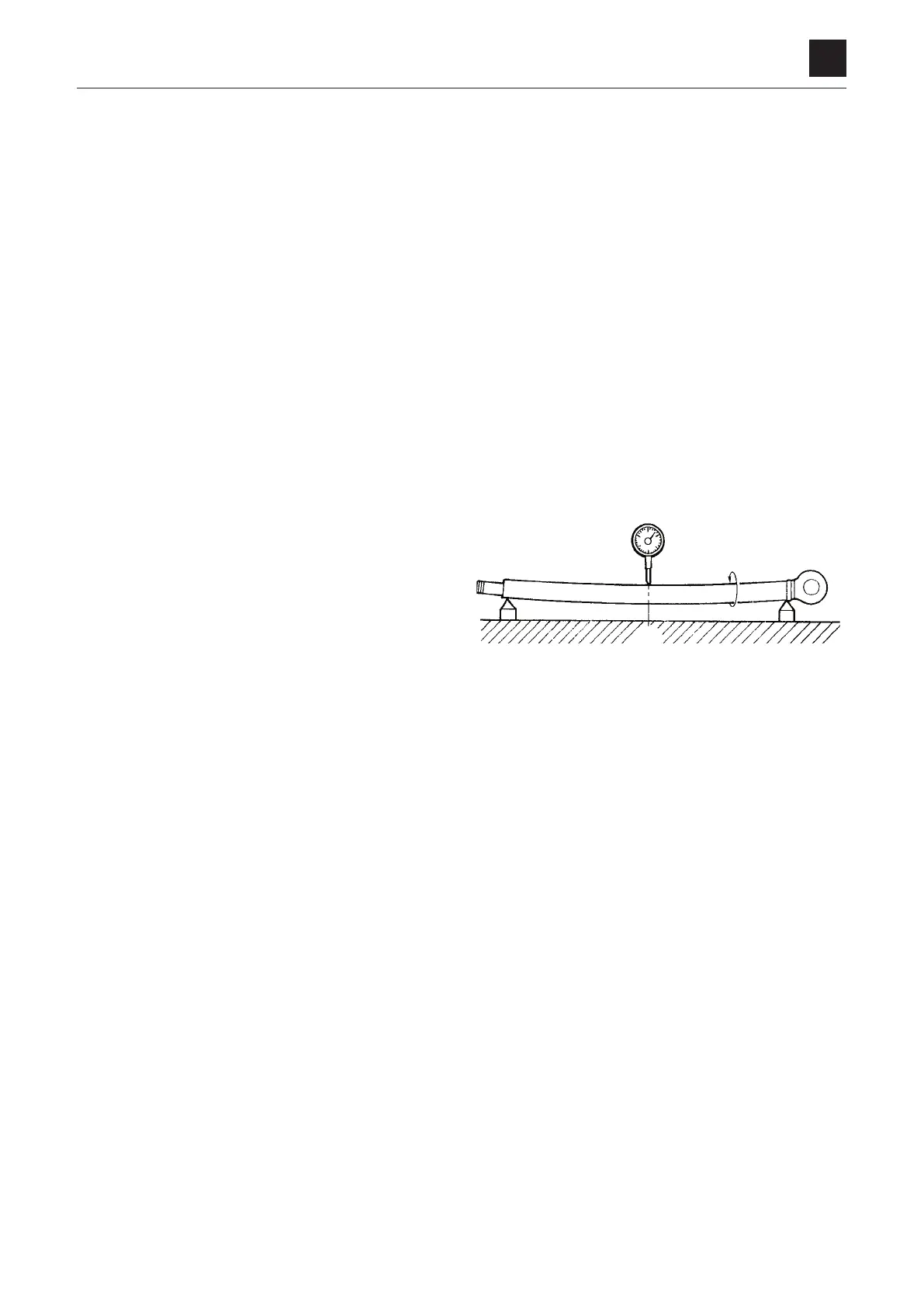

Measuring the bend

a. Support the portion of the rod with the same diam-

eter at both ends on V

-blocks.

b. Set a dial gauge at the center between the two

blocks.

c.

Rotate the rod and take a reading of the maximum

and minimum run-out indicated by the dial gauge. If

the bending of the rod is within the above limit, yet is

bent a lot in a small distance so that it will not move

smoothly, replace the rod if it makes a squeaking

sound in the operation test after reassembly or if it

catches during movement.

2. Tube

• If there are cracks in the welded portion, replace the

tube.

• Replace the tube if the inside surface is scratched or

if it leaks hydraulic oil.

• If the inner diameter of the clevis bushing is worn,

replace the bushing.

3. Rod cover

• If the bushing inner diameter is worn and the clear-

ance

with the piston rod is greater than 0.25 mm,

replace the bushing.

• If the inside surface of the bushing is scratched, and

the scratches are deeper than the depth of the coat-

ing layer

, replace the bushing.

Loading...

Loading...