5-55

5

TROUBLESHOOTING

SLEW MOTOR

SLEW MOTOR

If you notice that the noise or heat becomes unusually high, it is likely that there is a fault in the machine. If it occurs, stop

the machine immediately and try to locate the faulty section.

The table below shows the cause of the general problem and action to be taken when such problem occurs in the hydraulic

circuits.

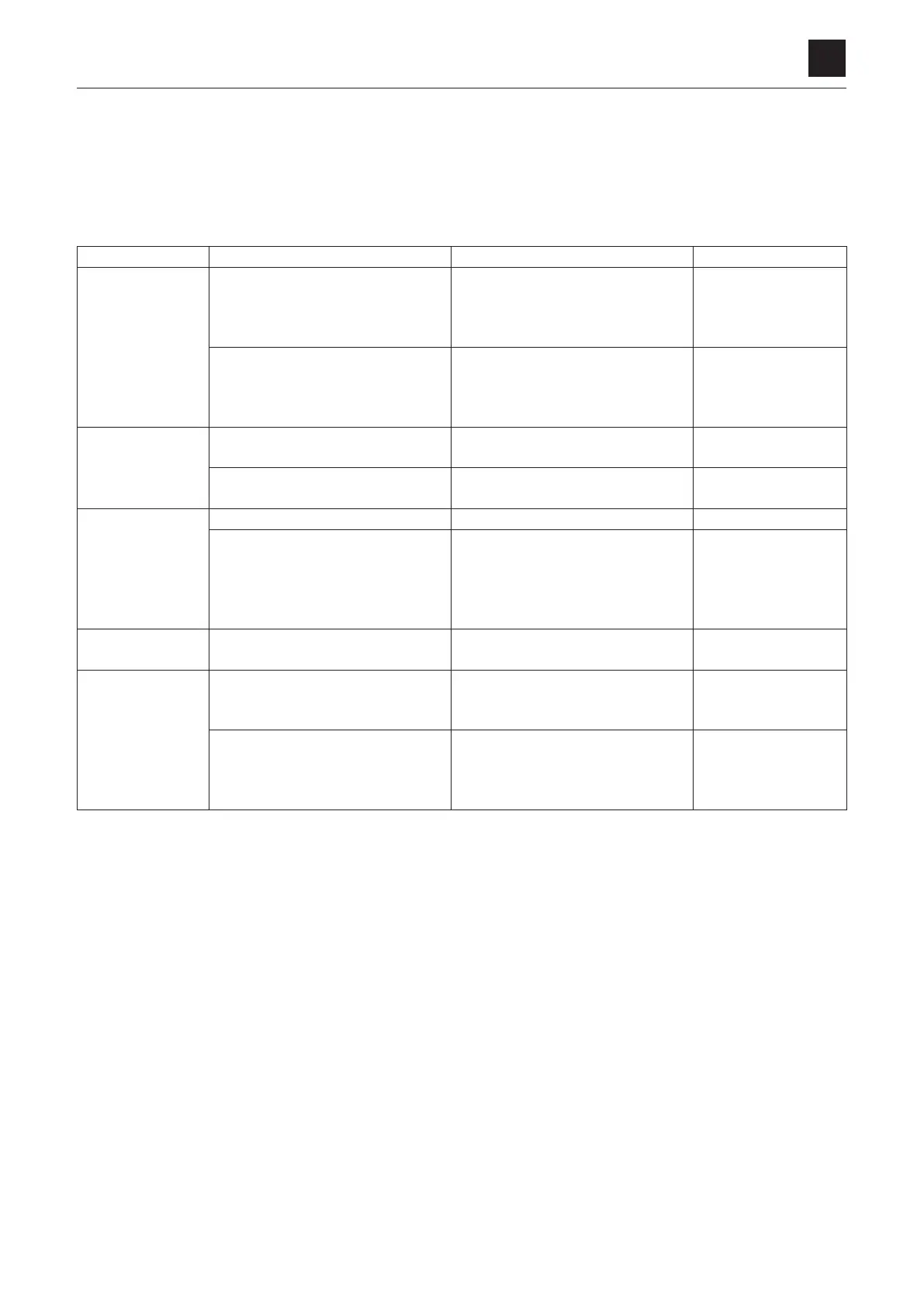

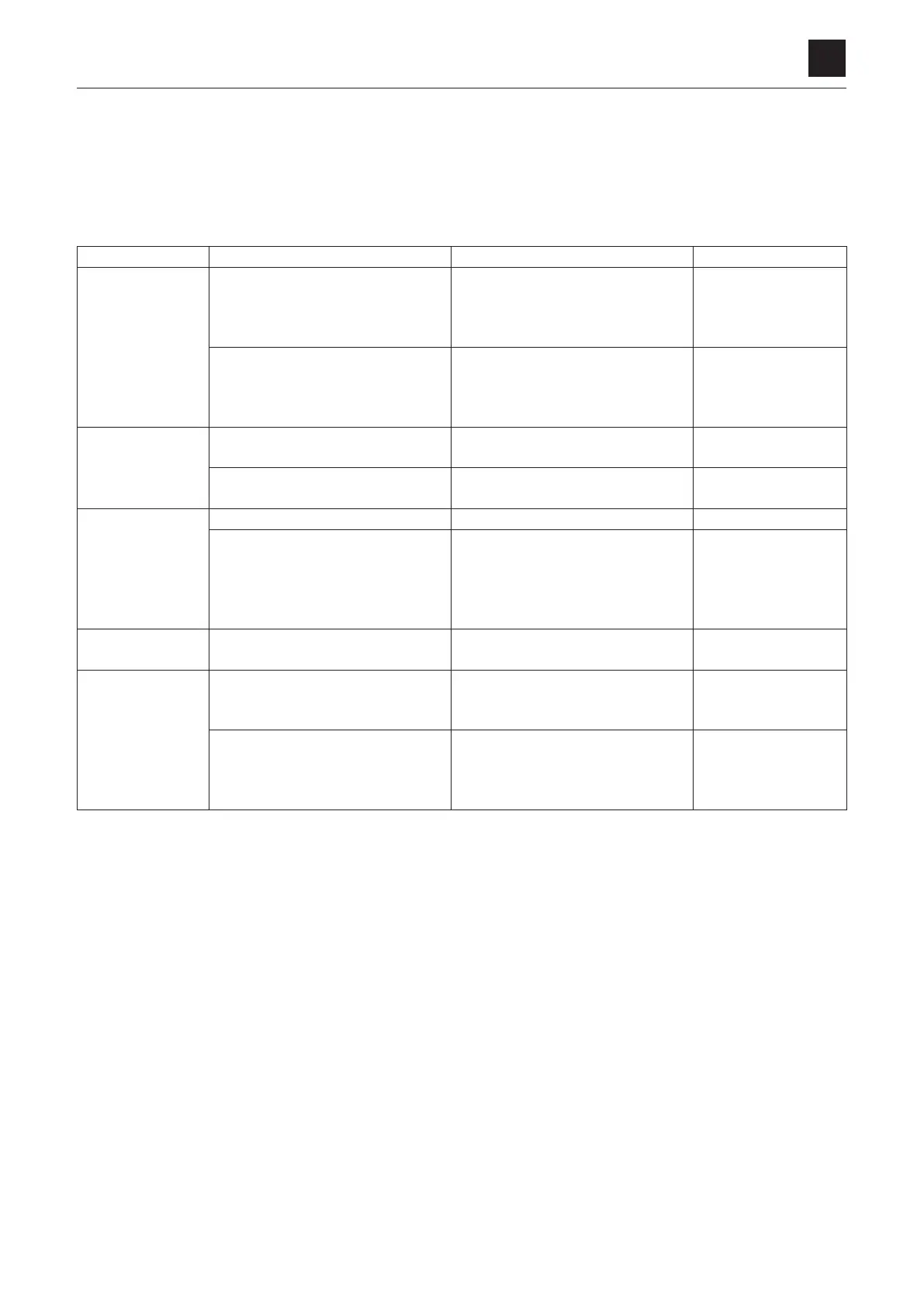

Hydraulic motor, brake valve

Symptoms How/Where? Major causes Remedies

Motor fails to start •

No pressure at the motor’s inlet

port

•

Set pressure of relief valve is too

low

• Pump faulty

• Control valve faulty

• Set correctly

• Repair or replace

• Repair or replace

• There is pressure at the motor’s

inlet port

•

Load is too heavy

• Hydraulic motor is faulty

• Reduction gears are faulty

• Reduce the load

• Repair or replace

• Replace the reduc-

tion gears

Motor

does not

speed up

•

Pump discharge is insufficient • Too much drain from the pump • Repair or replace

the pump

• Functional problem of the motor • Drop in the motor’s volumetric ef-

ficiency

•

Replace the motor

Oil is leaking •

Leaking from an oil seal • Lip is faulty • Replace the oil seal

• Leaking from the mating surface • Bolts are loose

• O-ring is faulty

• Mating surface is scratched

• Retighten the bolts

• Replace

• Repair the surface

with a grindstone or

sand paper

Motor

produces

abnormal noise

•

Noise in the piping • Piping support is faulty • Clamp the piping

Temperature in-

cr

ease at the re-

duction gears

•

Lubricating oil • Oil level is low

• Hydraulic oil is entered

• Add oil

• Replace the reduc-

tion gears

• Gear unit • Bearings are damaged

• Gear surfaces are damaged

• Replace the reduc-

tion gears

•

Replace the reduc-

tion gears

Loading...

Loading...