Theory

of

Operation-2445A/2455A Service

Comparator.

The

comparator will

then

begin

outputting

narrow pulses that

become

progressively wider

as

the

voltage

on

pin

4 settles to zero volts. These pulses drive

switching transistor 01050,

and

their slow progression

from narrow to wide causes the various secondary sup-

plies to gradually build

up

to their final operating levels.

The slow buildup prevents a turn-on current surge that

would cause the current-limit circuitry to shut down the

supply.

During startup, capacitor C1072 acts as a substantial

load,

and

a relatively large current flows

in

the windings of

T1050 for the first few cycles of Preregulator switching.

These strong current pulses ensure that storage capacitor

C1066 becomes charged sufficiently to start the Inverter

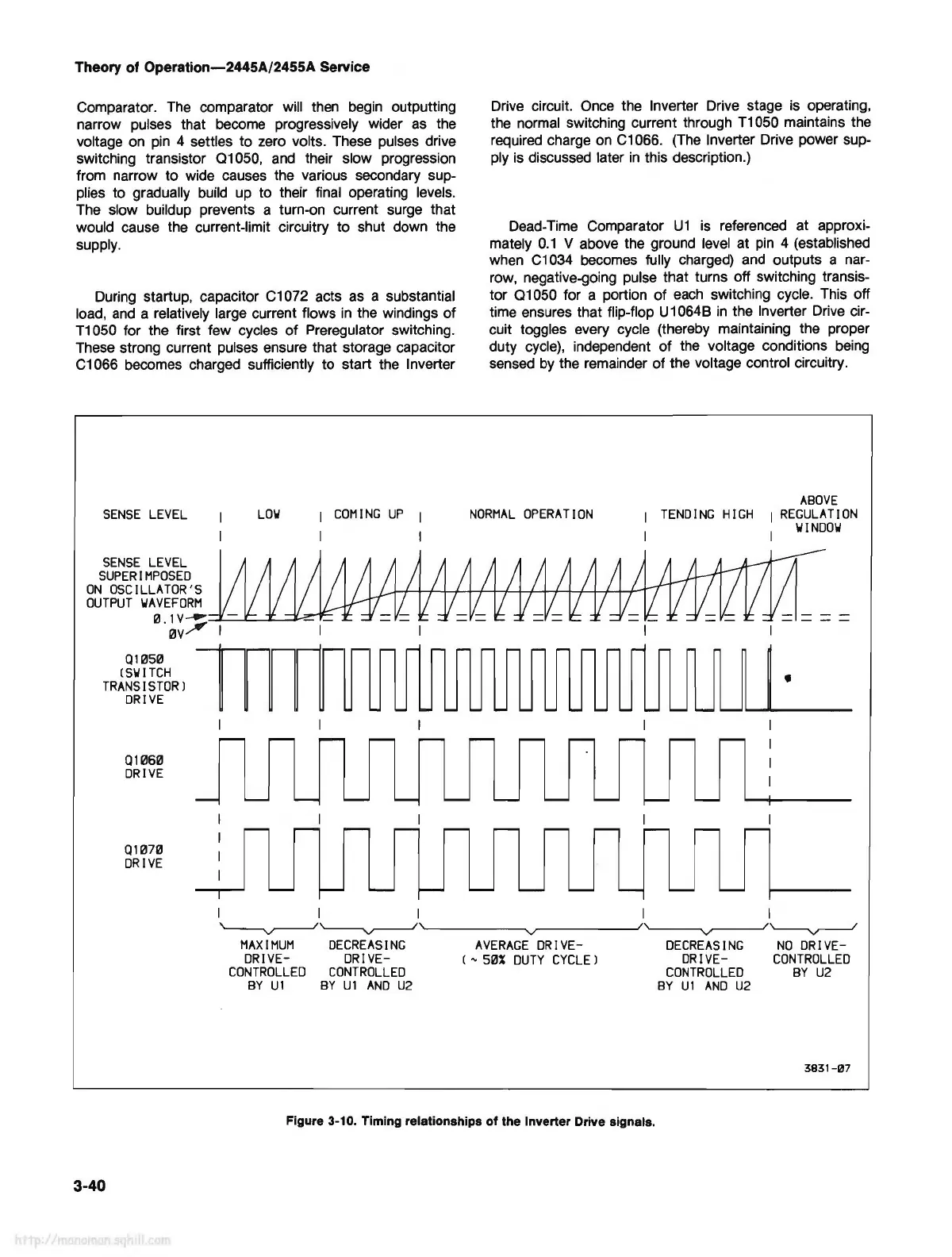

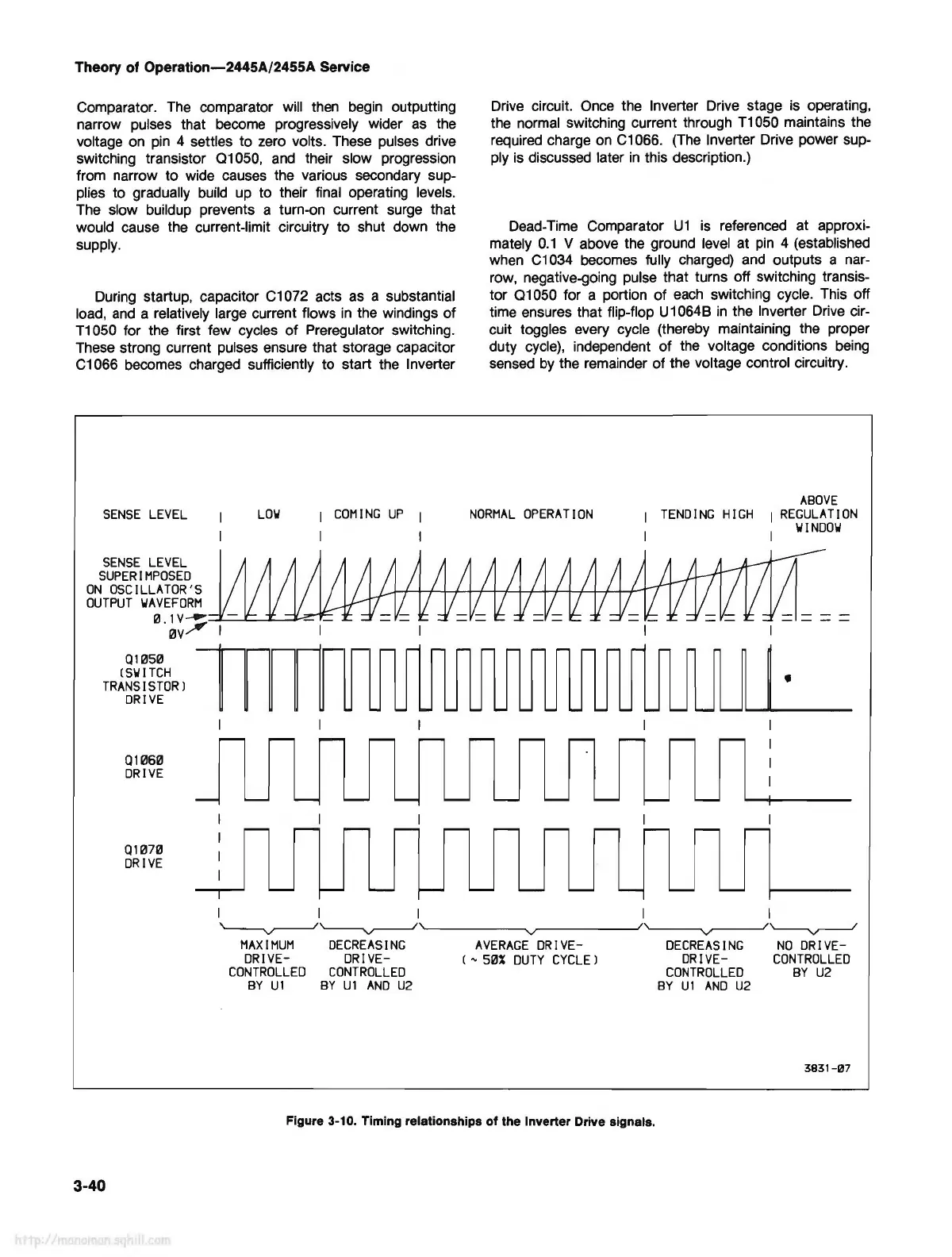

SENSE

LEVEL

SENSE

LEVEL

SUPERIMPOSED

ON

OSCILLATOR'S

OUTPUT

WAVEFORM

0.1V

0V

01050

(SWITCH

TRANSISTOR)

DRIVE

01060

DRIVE

01070

DRIVE

LOW

COMING

UP

Drive circuit.

Once

the Inverter Drive stage is operating,

the normal switching current through T1050 maintains the

required charge

on

C1066. (The Inverter Drive power sup-

ply

is

discussed later

in

this description.)

Dead-Time Comparator U 1 is referenced at approxi-

mately

0.1

V above the ground

level

at

pin

4 (established

when C1034 becomes fully charged)

and

outputs a nar-

row, negative-going pulse that turns off switching transis-

tor 01050 for a portion of

each

switching cycle. This off

time ensures that flip-flop U1064B

in

the Inverter Drive cir-

cuit toggles every cycle (thereby maintaining the proper

duty

cycle),

independent of the voltage conditions

being

sensed

by

the remainder of the voltage control circuitry.

NORMAL

OPERATION

ABOVE

TENDING

HIGH

REGULATION

WINDOW

I I I I

MAX

I

MUM

DECREASING

AVERAGE

DR

I

VE-

DECREASING

ND

DR

I

VE

DR

I

VE-

DR

I

VE-

(

DUTY

CYCLE

J

DR

I

VE

CONTROLLED

CONTROLLED

CONTROLLED

CONTROLLED

BY

U2

BY

Ul

BY

Ul

AND

U2

BY

Ul

AND

U2

Figure 3-10. Timing relationships of the Inverter Drive signals.

3-40

Loading...

Loading...