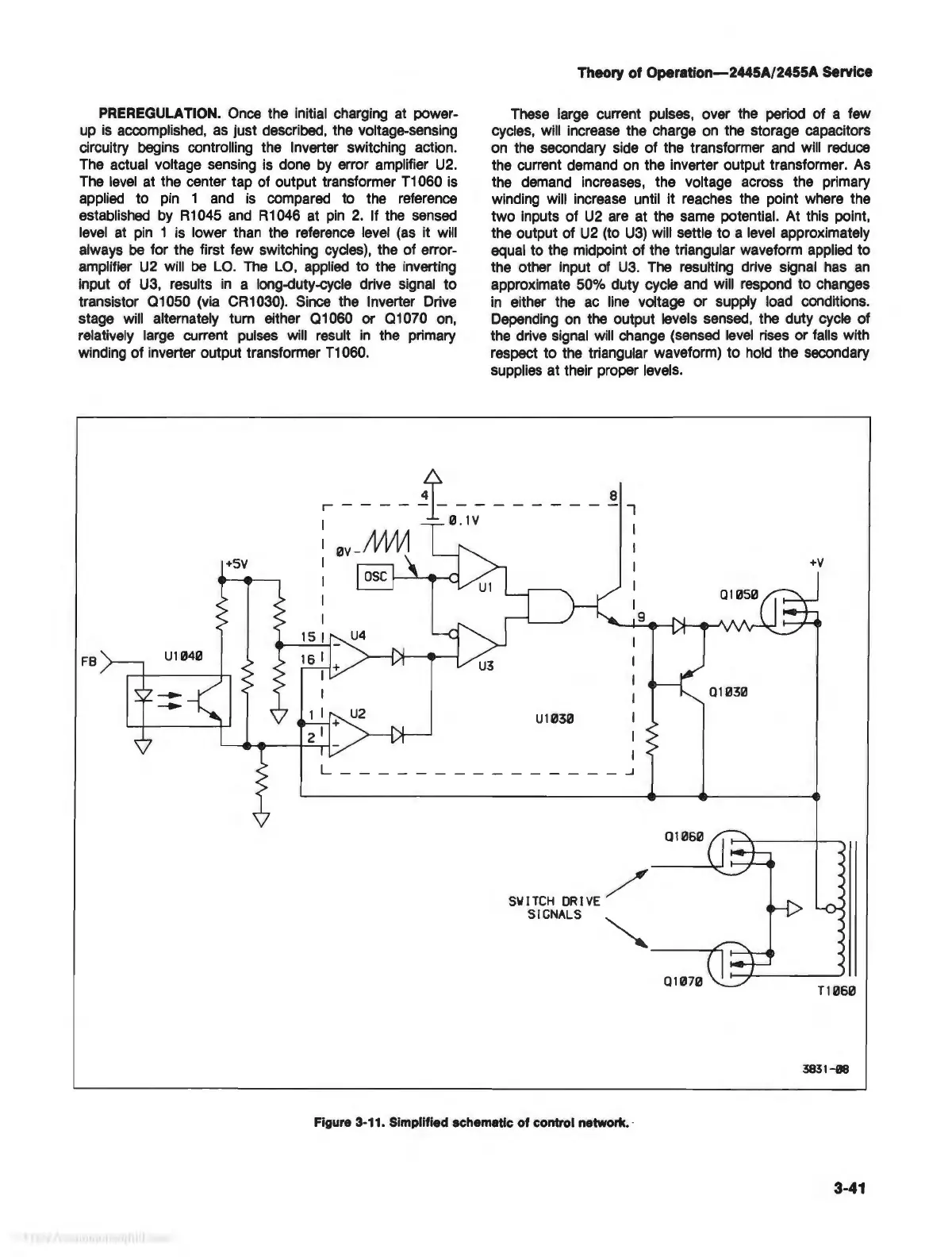

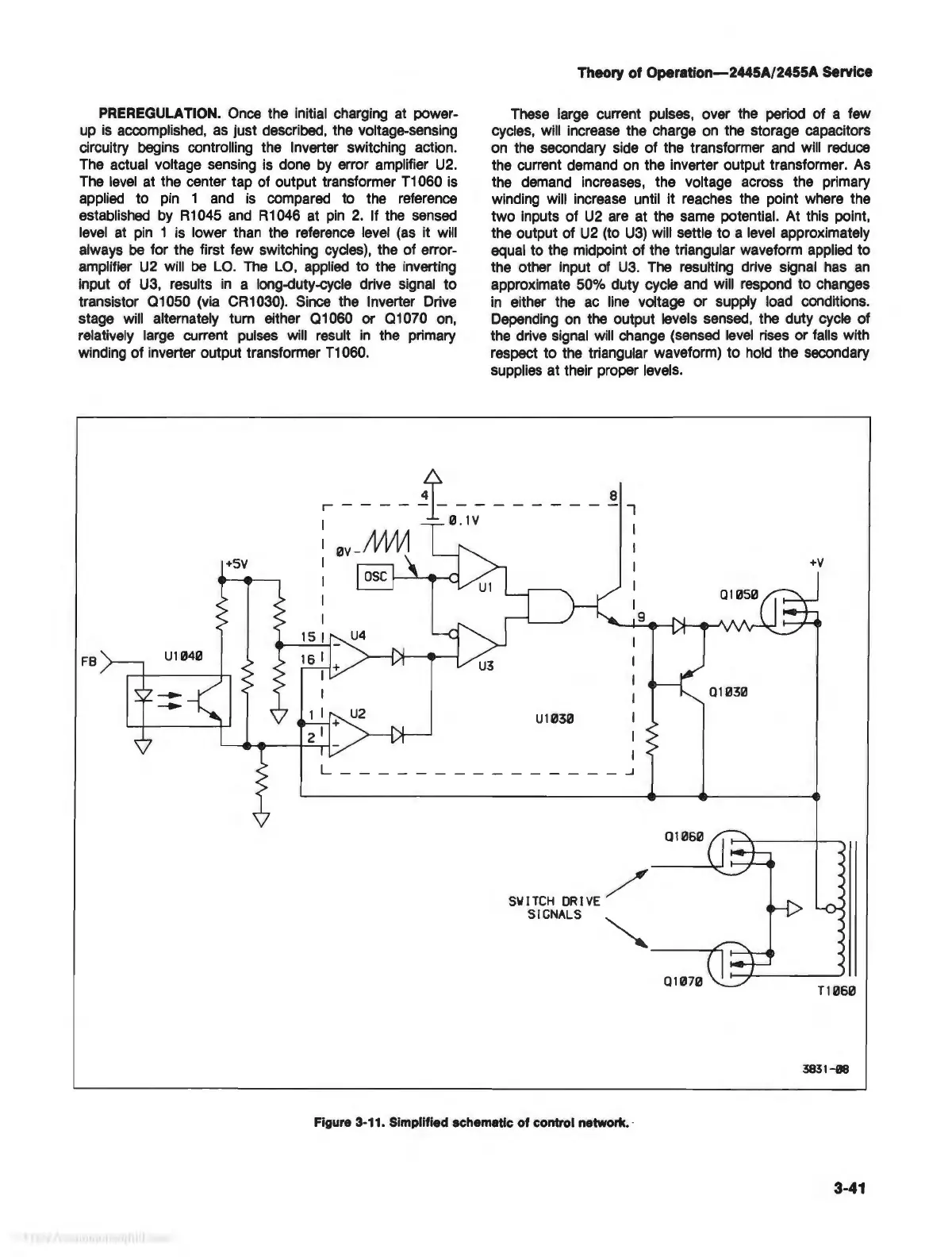

PREREGULATION.

Once

the initial charging

at

power-

up

is

accomplished,

as

just described, the voltage-sensing

circuitry begins controlling the Inverter switching action.

The

actual voltage sensing is done

by

error amplifier

U2.

The

level

at the center tap of output transformer

T1

060 is

applied to

pin

1

and

is

compared to the reference

established

by

R1045

and

R1046

at

pin

2.

If

the

sensed

level

at

pin

1 is lower than the reference level

(as

it will

always

be

for the first few switching cycles), the of error-

amplifier

U2

will

be

LO.

The

LO,

applied to the inverting

input of

U3,

results

in

a long-duty-eycle drive signal to

transistor 01050

(via

CR1030).

Since

the Inverter Drive

stage will alternately turn either 01060 or 01070

on,

relatively large current pulses will result

in

the primary

winding of inverter output transformer

T1060.

1 0 .

1V

FB

Theory of

Operation-2445A/2455A

Service

These

large current pulses, over the period of a few

cycles, will increase the charge

on

the storage capacitors

on

the secondary side of the transformer

and

will reduce

the current demand

on

the inverter output transformer.

As

the

demand

increases, the voltage across the primary

winding will increase until it reaches the point where the

two inputs of

U2

are

at the same potential. At this point,

the output of

U2

(to

U3)

will settle to a

level

approximately

equal to the midpoint of the triangular waveform applied to

the other input of

U3

.

The

resulting drive signal

has

an

approximate 50% duty cycle

and

will respond to changes

in

either the

ac

line

voltage or supply load conditions.

Depending

on

the output levels sensed, the duty cycle of

the drive signal

will

change (sensed

level

rises or falls with

respect to the triangular waveform) to

hold

the secondary

supplies at their proper levels.

8

I

01060

SWITCH

SIGNALS

___

11060

Figure 3-11. Simplified schematic of control

3-41

Loading...

Loading...