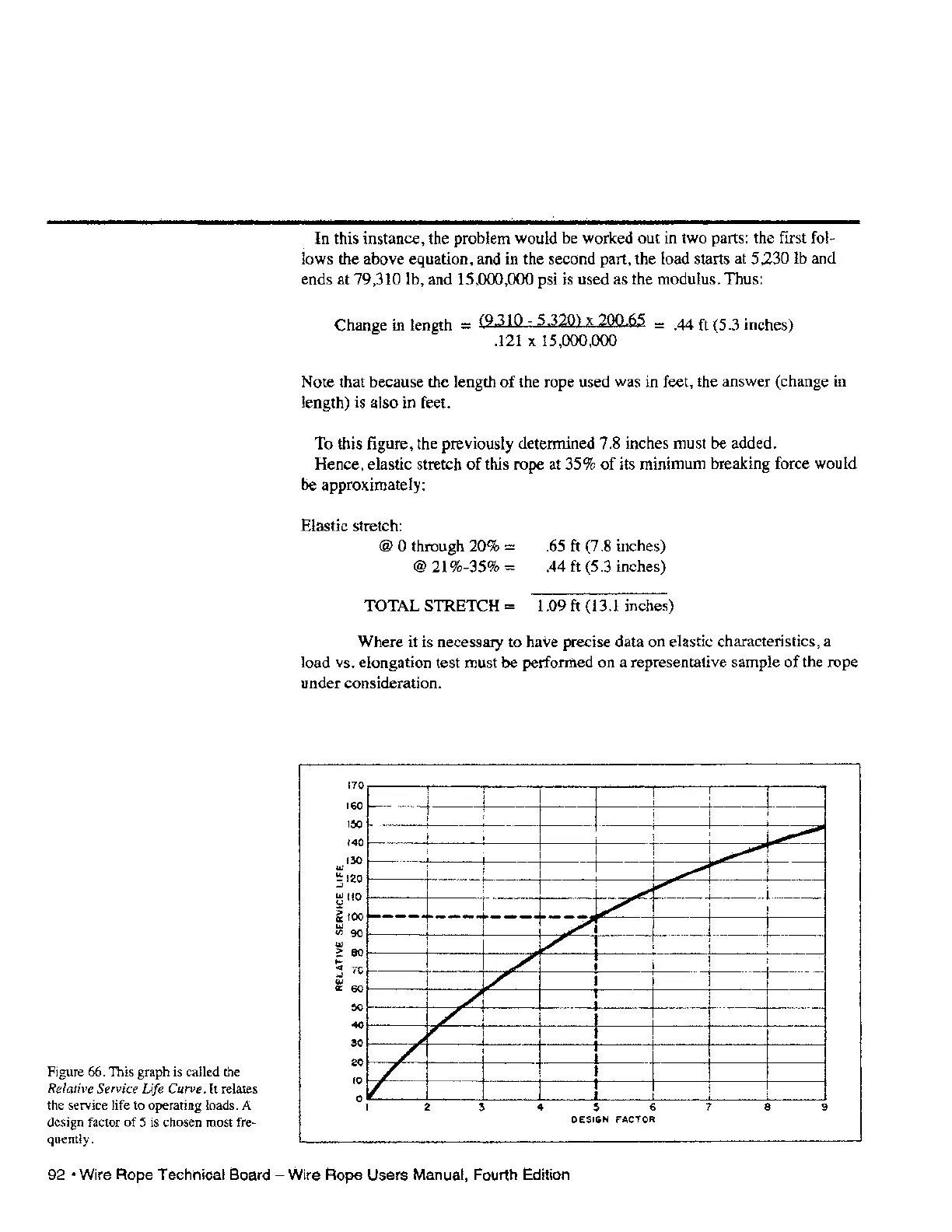

Figure 66. This graph is called the

Relative Service Life Curve. It relates

the service life to operating loads. A

design factor

of

5 is chosen most fre-

quently.

In

this instance, the problem would be worked out in two parts: the first fol-

lows

the above equation, and in the second part, the ioad starts at 5,230

Ib

and

ends at 79,310

lb,

and 15,000,000 psi is used as the modulus. Thus:

Change in length

= (9.310 - 5,320) x 200.65 = .44 ft (5.3 inches)

...

.121 x 15;000,000

Note that because the length

of

the rope used was in feet, the answer (change in

length) is also in feet.

To this

figure

j

the previously determined 7.8 inches must be added.

Hence, elastic stretch

of

this rope at 35%

of

its minimum breaking force would

De

approximately:

Elastic stretch:

@ 0 through 20% =

@ 21%-35% =

TOTAL STRETCH

:::

.65

ft

(7.8 inches)

.44

ft (5.3 inches)

1.09

ft

(13.1 inches)

Where it is necessary

to

have precise data on elastic characteristics, a

load vs. elongation test must be

perforl1led on a representative sample

of

the rope

under consideration.

...,.

170

160

150

140

130

3

120

~IIO

~

100

...,

CI'i

90

!oJ

~80

....

;:\1C

...

11::60

50

40

30

20

10

o

~-

...

-

jo----

/

./'

~~

./

7

1/

1

2

~

I

I

~,

:/

.JII'

~

._

..........

""

............

I7'

7 .

V

./

;

-_.-

-.-.¥.~-.~-

1/

I

I

I

4

~

6

7

8 9

DESIGN FACTOR

92·

Wire

Rope

Technical

Board

-

Wire

Rope

Users

Manual, Fourth Edition

Loading...

Loading...