VISCOSITY: Oils are available in various grades (vis-

cosities). The ISO (International Organization for Stan-

dardization) viscosity classification system is currently

being adopted. The ISO grade applies strictly to vis-

cosity and does NOT imply type of oil. (engine, anti-

wear, hydraulic, gear.etc.). A viscosity grade should be

selected that will meet the minimum start up tempera-

ture requirement and the maximum operating hydrau-

lic oil temperature.

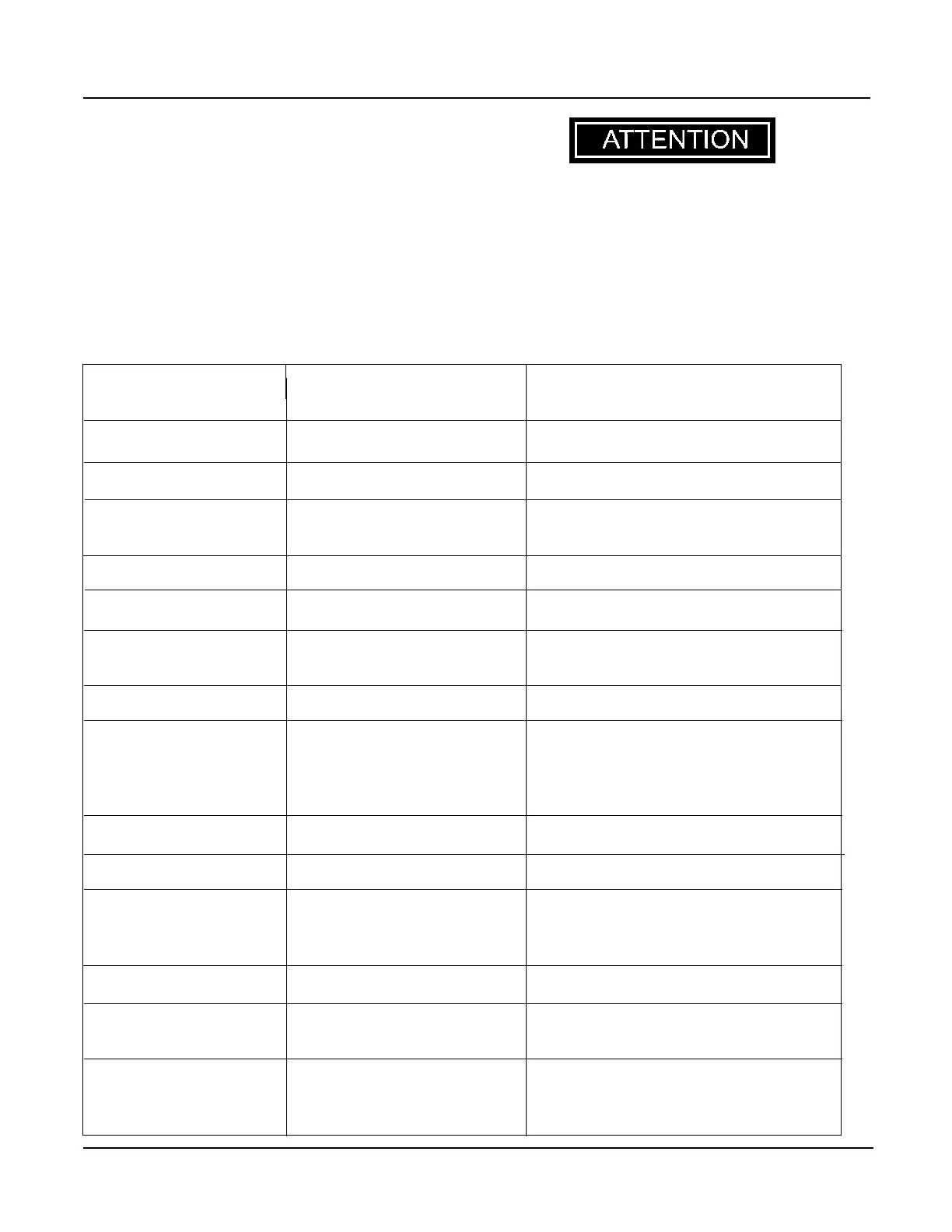

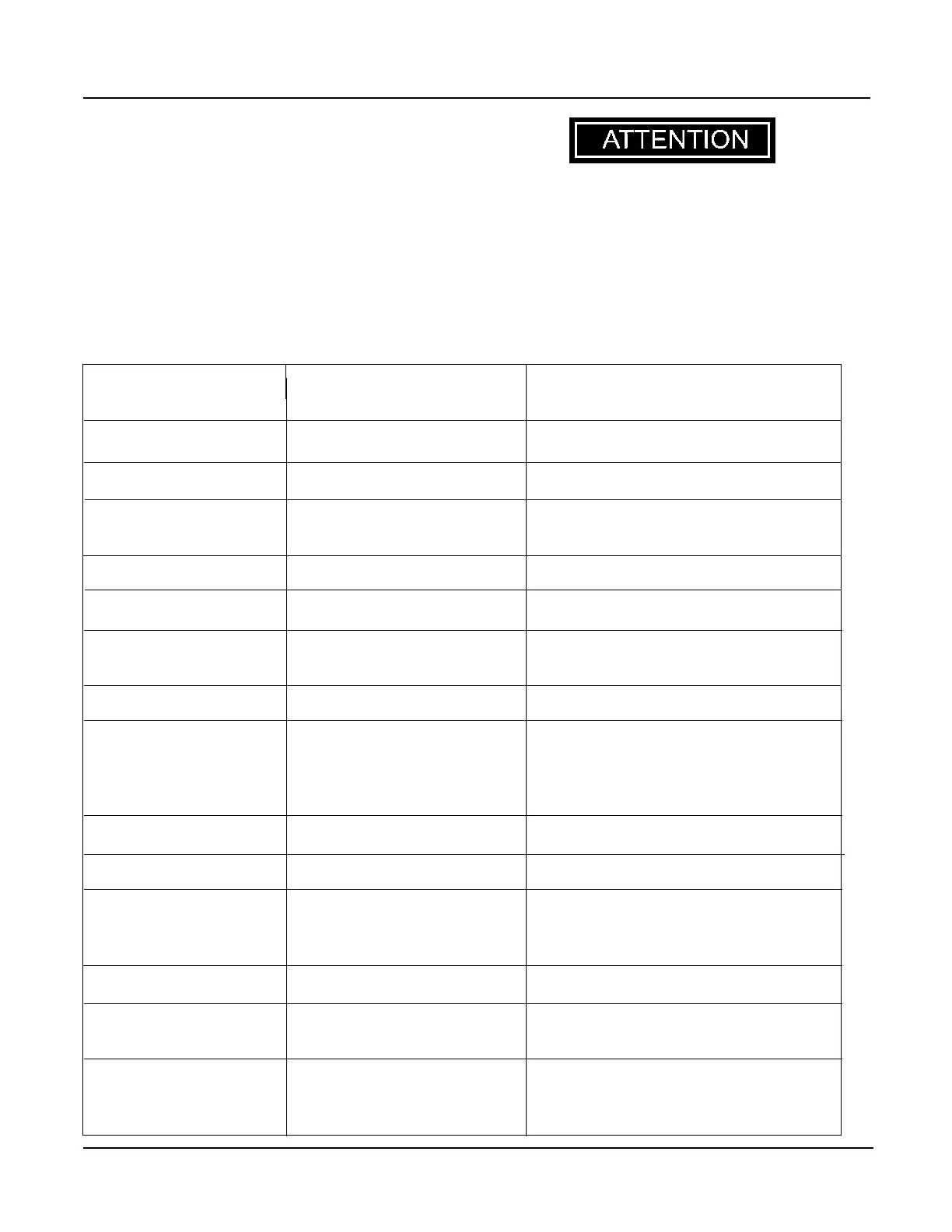

MAINTENANCE AND LUBRICATION

PHYSICAL

PROPERTIES

A. A.P.I. Gravity

B. FLash Point

C. Viscosity Index 100°F

210°F

D. Viscosity Index

E. Pour Point

F. Oxidation Test

to 2.0 Neut. No.

G. Rust Test

H. Foam Test

I. Demulsibility

J. Aniline Point

K. Pump Wear

L. % Zn

M. Filterability

N. Cleanliness

TEST METHOD

ASTM D287

ASTM D92

ASTM D445

ASTM D445

ASTM D2270

ASTM D97

ASTM D943

ASTM D943

ASTM D665 Procedure A

ASTM D892

Sequence l

Sequence 11

Sequence lll

ASTM D1401to 40-37-3 point

ASTM D611

Dennison HFO

or Vickers M2905 (100

Hrs.@150° F)

ASTM D1549

REQUIRMENT

28 Min.

380° F Min.

200-220 SSU

46 SSU MIn.

95 Min.

-25° F Max.

2500 Hours Min.

2500 Hours Min.

Pass

Foam Tendency Foam Stability

25 ml Max.Nil

50 ml Max.10 ml Max.

25 ml Max.Nil

30 Min. Max.

200-230° F

Satisfactory

.07 Min.

Fluid shall show no additive loss when

filtered through 5.0 micron filter.

Fluid shall appear bright and clear

and shall be free of visible contami-

nants or sludge.

HYDRAULIC OIL (Initial Fill)

KOEHRING SPEC 805 DATA

This machine is factory filled with Koehring spec

805 hydraulic fluid that is acceptable for start-up

at ambient temperatures of 20°F and should not

be operated above a hydraulic reservoir temper-

ature of 200°F. If these limits are exceeded dam-

age can result. For operation outside these

ranges, select the proper hydraulic fluid from the

charts on this and the following pages or from a

reputable supplier.

4 - 23 Revised: March 2005RT700 Series

Loading...

Loading...