9-19 TA9 & TA10 Dumper 0803-3 December 2010

Maintenance

Gearbox and Transfer Box

General

NO adjustments are necessary to any of these units, all that is

required is adherence to the lubrication schedule on page 9-28.

Oil Changes

An initial oil change and flush is recommended after the

transmission is placed in actual service. This change should be

made at any time following 50 hours in service, but should not

exceed 100 hours. An oil change and flush should be scheduled

for every subsequent 500 hours of operation. When changing

the oil it is essential to renew the oil filter and clean out the

suction strainer. The object in draining the oil is to eliminate

possible bearing surface abrasion and attendant wear. Minute

particles of metal, the result of normal wear in service are

deposited in and circulated with the oil. Oil changes are best

carried out when the transmission is thoroughly warm - NOT

HOT!

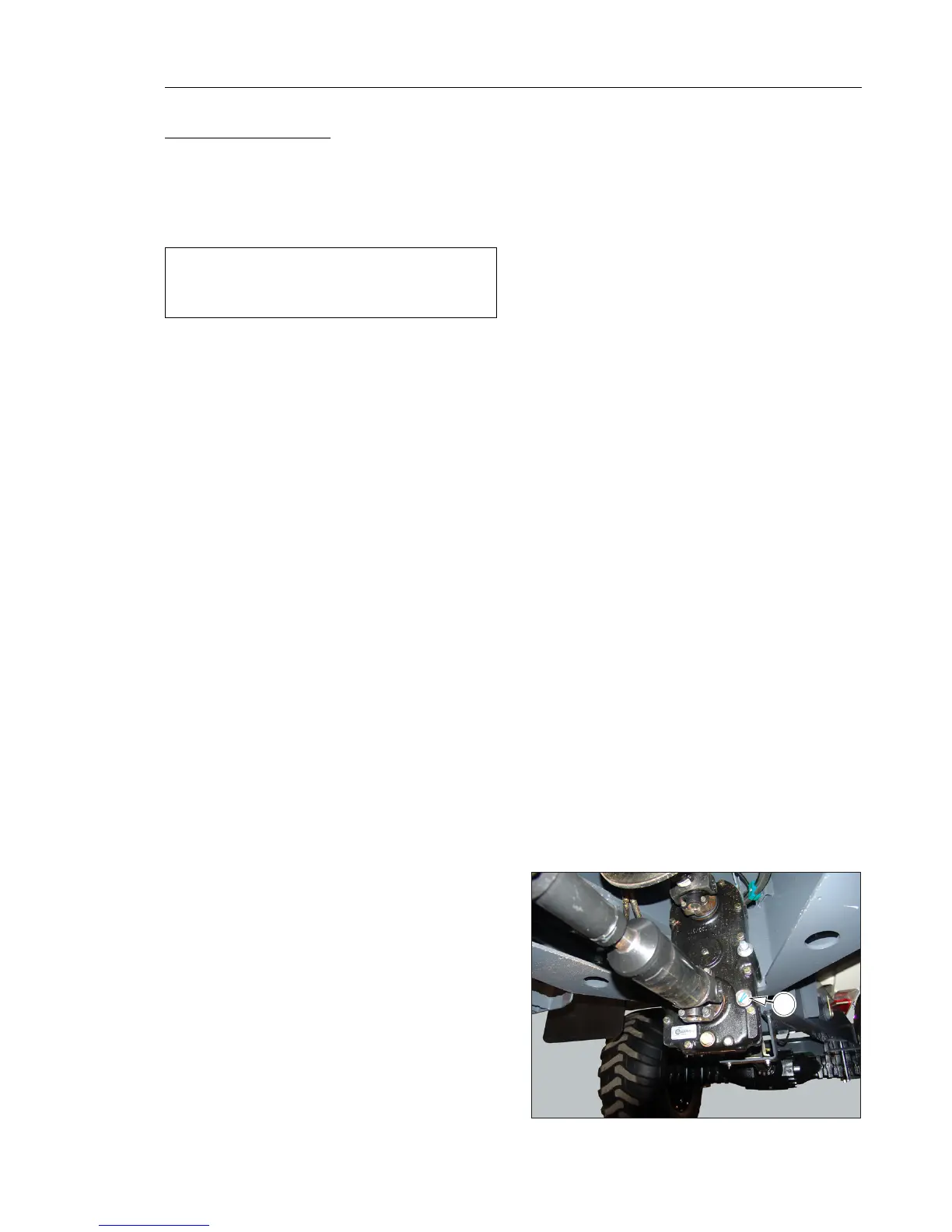

Transfer Box

• Position the machine on firm, level ground.

• Clean dirt from around filler plug (A).

• Fill the transfer box through the filler/level hole (A), with the

correct grade of oil, until the oil begins to flow from the

level/filler hole (A).

• Replace the plug (A) and tighten.

Refer to Lubrication Schedule for correct grade of oil.

NOTICE

Always Position Machine on Firm, Level Ground when

Checking Fluid Levels

Loading...

Loading...