Maintenance

TA9 & TA10 Dumper 0803-3 December 2010 9-24

b Seat Belts

Important Facts about Seat Belts

The potential exposure of this seat belt to severe environmental

conditions make it crucial to inspect the seat belt system

regularly.

It is recommended that the seat belt system is inspected at least

once a year or more often if the vehicle is exposed to severe

environmental or vocational conditions,

Any seat belt system that shows cuts, fraying, extreme or

unusual wear, significant discoloration due to UV exposure,

dusty-dirty conditions, abrasion to the seat belt webbing, or

damage to the buckle, latch plate, retractor, hardware or any

other obvious problem should be replaced immediately.

Once replacement of the seat belt has been determined, be

certain that it is only replaced with the original equipment

manufacturer recommended replacement seat belt. See your

authorized spares and service centre for replacement. Your

restraint system has been developed and tested specifically for

your machine.

If the inspection indicates that any part of the seat belt requires

replacement, the entire belt must be replaced. It is vitally

important that all components be mounted back in the same

position as the original components which were removed. This

will maintain the design integrity of the mounting points for the

seat belt assembly.

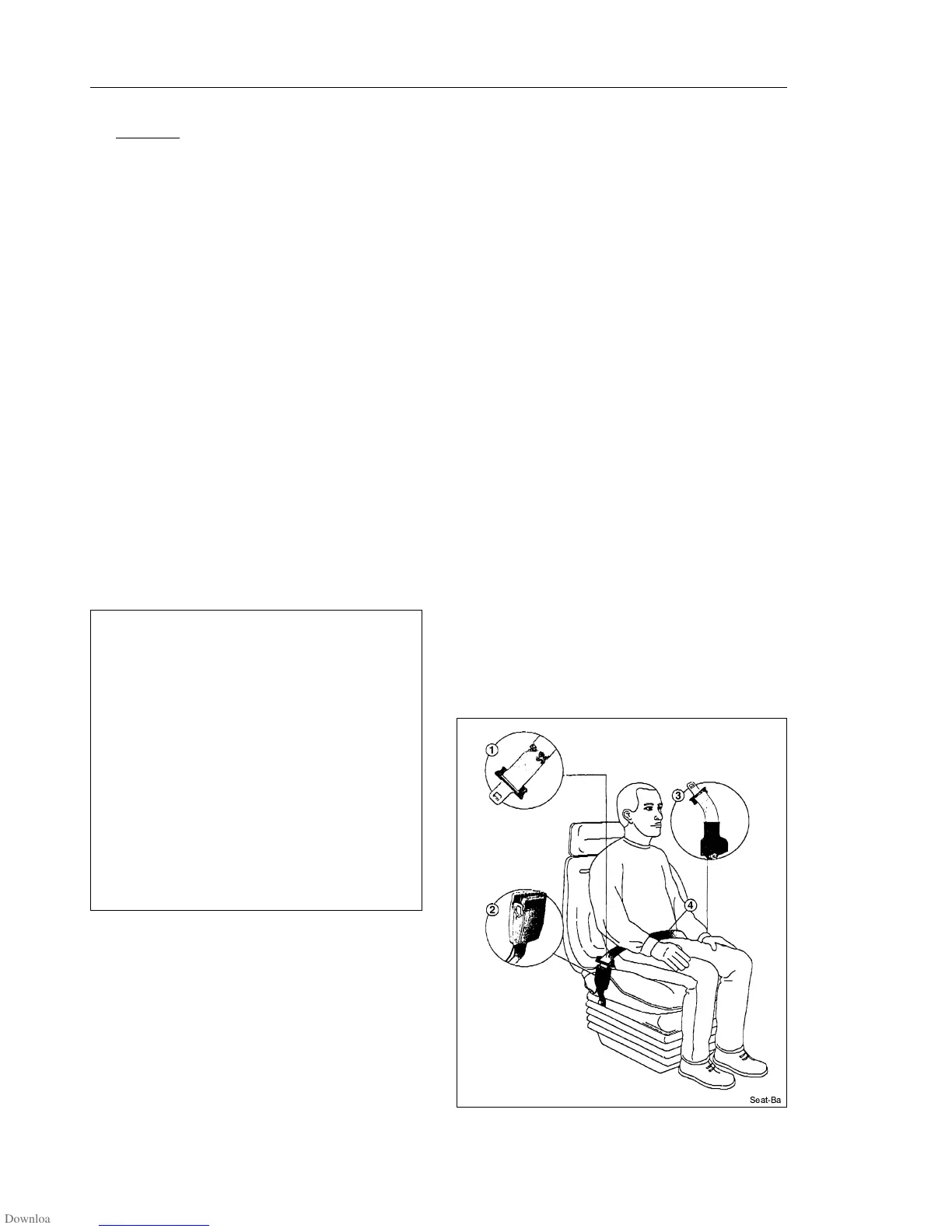

Seat Belt Maintenance Guidelines

Follow Maintenance Guidelines 1-4 to properly inspect seat belt

and tethers to determine if replacement is necessary.

The following maintenance guidelines detail how to Inspect

seat belt for “cuts, fraying, extreme or unusual wear of the

webbing, etc., and damage to the buckle, retractor, hardware or

other factors” which indicate that seat belt replacement is

necessary,

• Check the webbing. Pull the webbing completely out of the

belt retractor and inspect the full length of the webbing for

cuts, wear, fraying, dirt and stiffness. If a belt shows any

cuts, fraying, extreme or unusual wear, the system should be

replaced.

• Check the buckle and latch for proper operation and to

determine if latch plate is excessively worn, deformed or

buckle is damaged or casing broken.

• Check retractor web storage device operation by extending

webbing to determine it locks properly and that it spools out

and retracts webbing properly - fitted.

Check web in areas exposed to ultraviolet rays from the sun or

extreme dust or dirt. If the original colour of the web in these

areas is extremely faded and/or the web is packed with dirt, the

physical strength of this web may have deteriorated. If this

condition exists replace the system.

b

Failure to properly inspect and maintain a seat belt can

cause serious injury or loss of life in the event of an

accident.

It is critical that any time the machine is involved in an

accident, the entire seat belt system must be replaced.

The seat belt should be considered to have a finite life

and must be replaced as required throughout the life of

the machine.

The seat belt must be inspected daily for required

maintenance.

If replacement of any part of the seat belt is indicated

through maintenance guidelines below, the entire belt

must be replaced, both retractor and buckle sides.

Loading...

Loading...