9-1 TA9 & TA10 Dumper 0803-3 December 2010

Maintenance

Maintenance and Lubrication

Before carrying out any service or maintenance work ensure

that the following precautions have been taken.

• Place the machine on firm level ground.

• Stop engine and chock the wheels.

• Remove Start key to prevent accidental starting.

• Place a warning tag on the machine to prevent accidental

start up.

• Only jack or raise the dumper using the correct equipment.

• Refer to the Service Schedule on Page 9 -27

• When checking fluid levels the machine must be placed on a

firm, level surface, in a well ventilated position away from

naked flames, grinding sparks etc.

• Ensure strict cleanliness is observed especially when dealing

with hydraulic systems.

• Isolate electrical system by using the isolator switch or by

disconnecting the battery.

• Ensure all guards and covers removed during maintenance

are replaced before the machine is put back into work.

Safety Signs

All safety signs fitted to the machine must be legible.Use mild

soap and water to clean safety signs -DO NOT use solvent based

cleaners because they may damage the safety sign material. All

safety signs MUST be replaced immediately they become

damaged or unreadable.

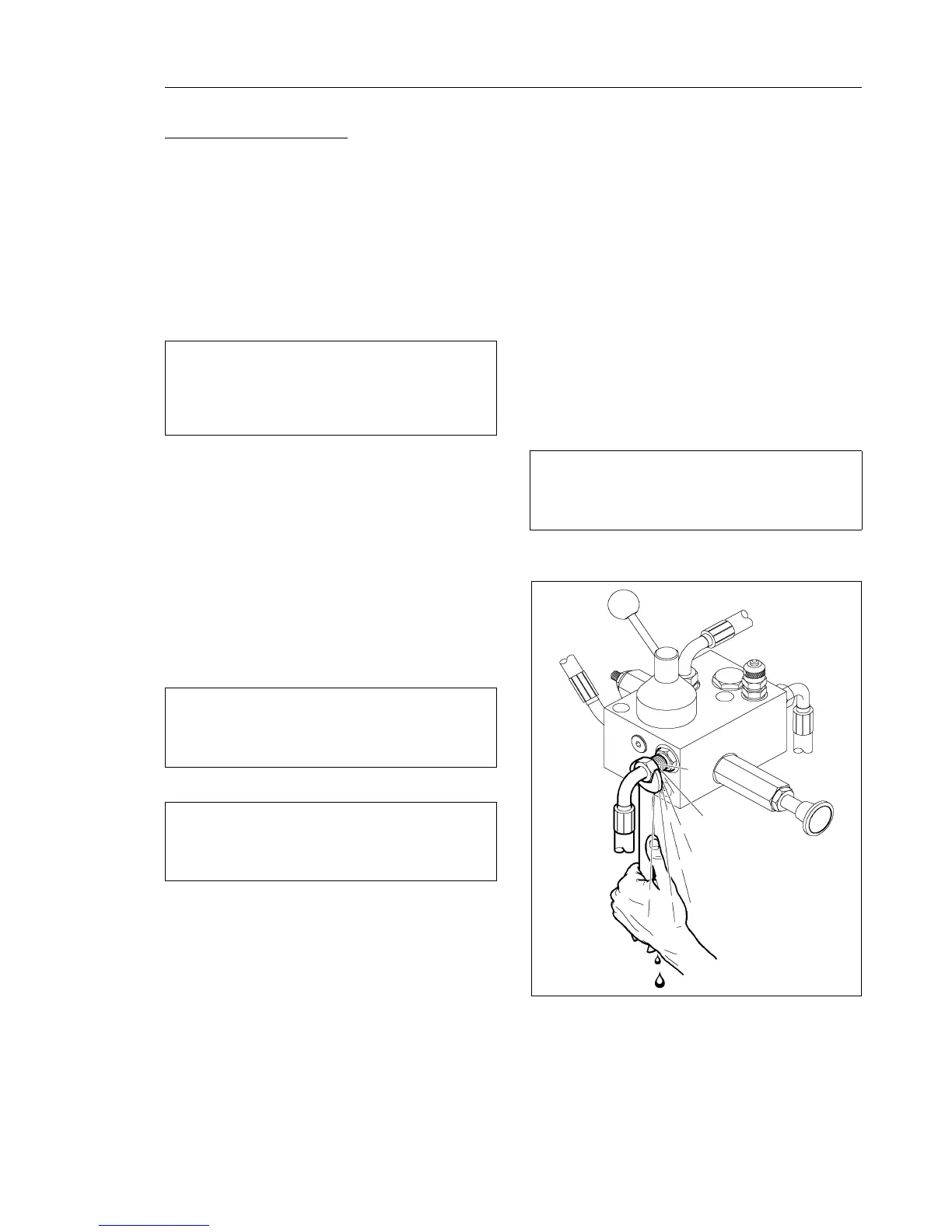

Hydraulic Oil Under Pressure

• Release any pressure in the hydraulic circuit before carrying

out any repairs to the hydraulic system or components.

• Fine jets of hydraulic fluid under pressure can penetrate the

skin.

• Do not use your fingers to check for small leaks or expose

uncovered areas of your body to leaks.

• Check for leaks using a piece of cardboard.

b

Always use Axle Stands or other acceptable rigid support

of ample capacity to support the dumper when raised

clear of the floor.

b

Refer to the SAFETY Section of this manual before

performing any maintenance tasks on this machine.

b

Never work under a raised skip unless the skip props are

LOCKED in position.

b

If skin is penetrated with Hydraulic Fluid, Get Immediate

Medical Help

Loading...

Loading...