32

7 Operation of the power supply EX-TRAFIRE

®

105HD

7.7.1 Table for FHT-EX

®

105TT material removal

1 Use gouging consumables suitable

to the cutting torch being used.

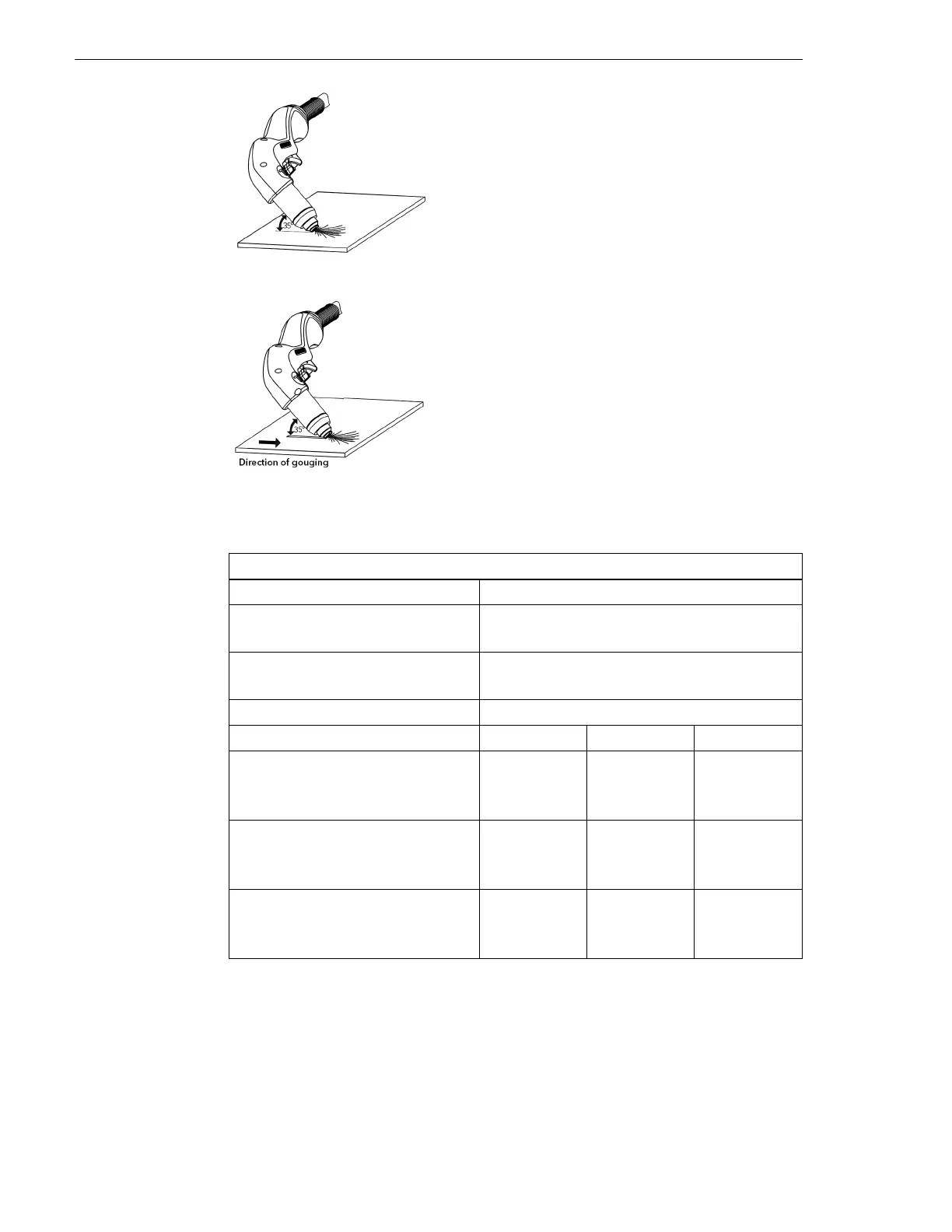

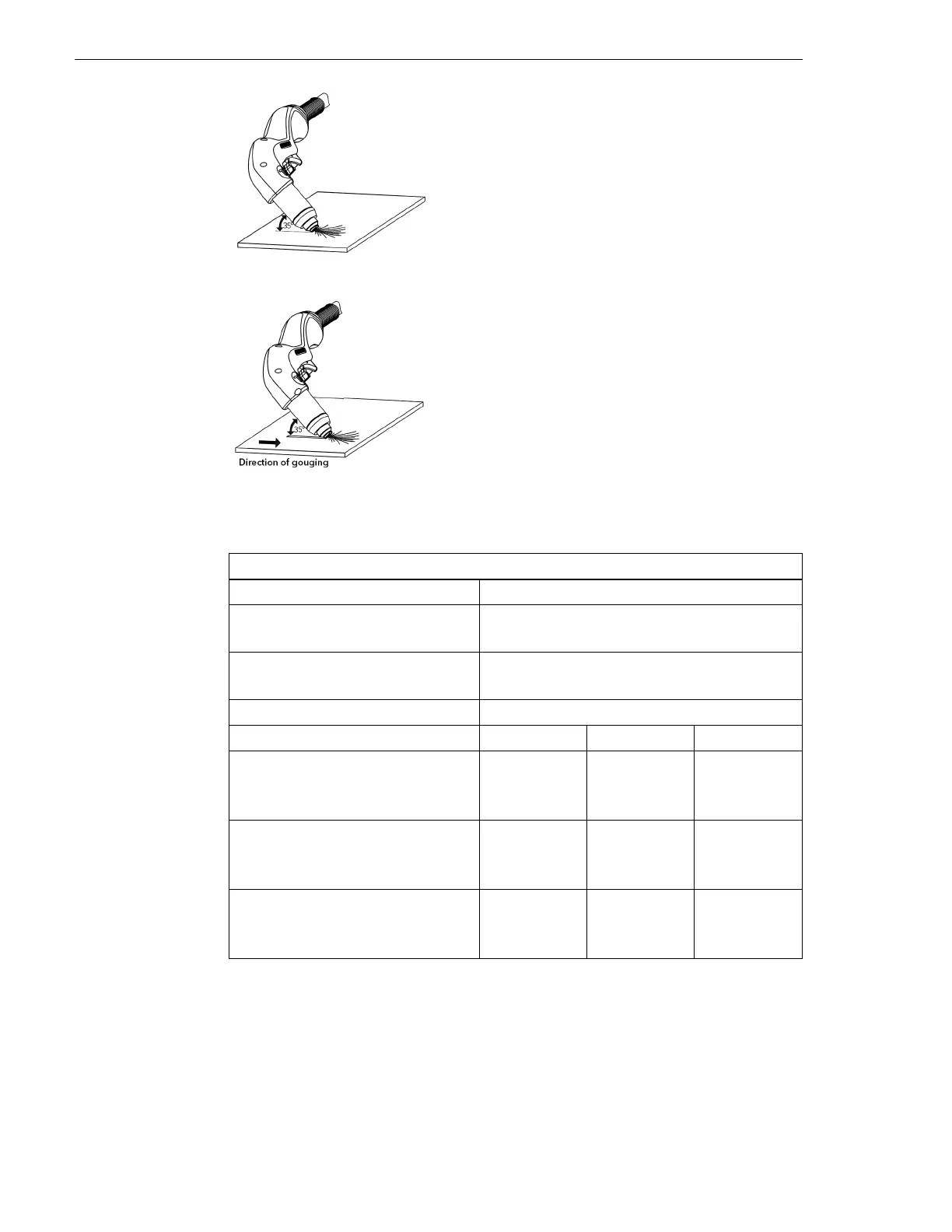

2 Hold the cutting torch at an angle of

30° to 35° inclined to the workpiece.

3 Hold the nozzle close enough to the

workpiece that it touches the

workpiece.

4 Press the torch trigger to ignite the

arc.

5 Continue to hold the cutting torch at

an angle of 30° to 35° to the

workpiece and move it in the

direction of the material to be

removed.

Table 11 Table for FHT-EX

®

105TT material removal

Gouging parameters

(Dynamic) air pressure 75 psi (5.2 bar)

Distance between cutting

torch and workpiece

As close as possible

Angle of cutting torch to

workpiece

30° to 35°

Speed 23 in/min. (0.6 m/min.)

Current 65 A 85 A 105 A

Removal rate for mild steel Approx.

11 lb/hr

(4.8 kg/h)

Approx.

17 lb/hr

(7.74 kg/h)

Approx.

20 lb/hr

(9.0 kg/h)

Width of gouge Approx.

0.21 in

(5.5 mm)

Approx.

0.22 in

(5.7 mm)

Approx.

0.24 in

(6.2 mm)

Depth of gouge Approx.

0.17 in

(4.5 mm)

Approx.

0.18 in

(4.8 mm)

Approx.

0.16 in

(4.1 mm)

Loading...

Loading...