INSTALLATION PROCEDURES 20 Manual 0-2568

NOTE

A typical 50 lb. CO2 cylinder can deliver a con-

tinuous flow rate of 35 scfh (16.5 lpm). To obtain

the required flow rate for the torch, it may be nec-

essary to manifold several CO2 cylinders. Con-

tinuous flow requirements will depend on the spe-

cific application and duty cycle.

C. Using Water Secondary

NOTES

Tap water should only be used as a secondary gas

on machine torches.

The tap water source does not need to be deionized,

but in water systems with extremely high mineral

content a water softener is recommended.

Tap water can be used instead of a secondary gas and is

connected to the Power Supply as follows:

1. The tap water source must be capable of delivering a

minimum water pressure of 50 psi (3.5 BAR) and flow

of 8 gph (35.2 lph).

2. Connect the tap water supply hose to the input of a

Water Pressure Regulator.

3. Connect the output of the water regulator to the fitting

marked SEC. WATER on the rear panel of the Power

Supply.

NOTE

The water source does not need to be deionized,

but in water systems with extremely high mineral

content a water softener is recommended.

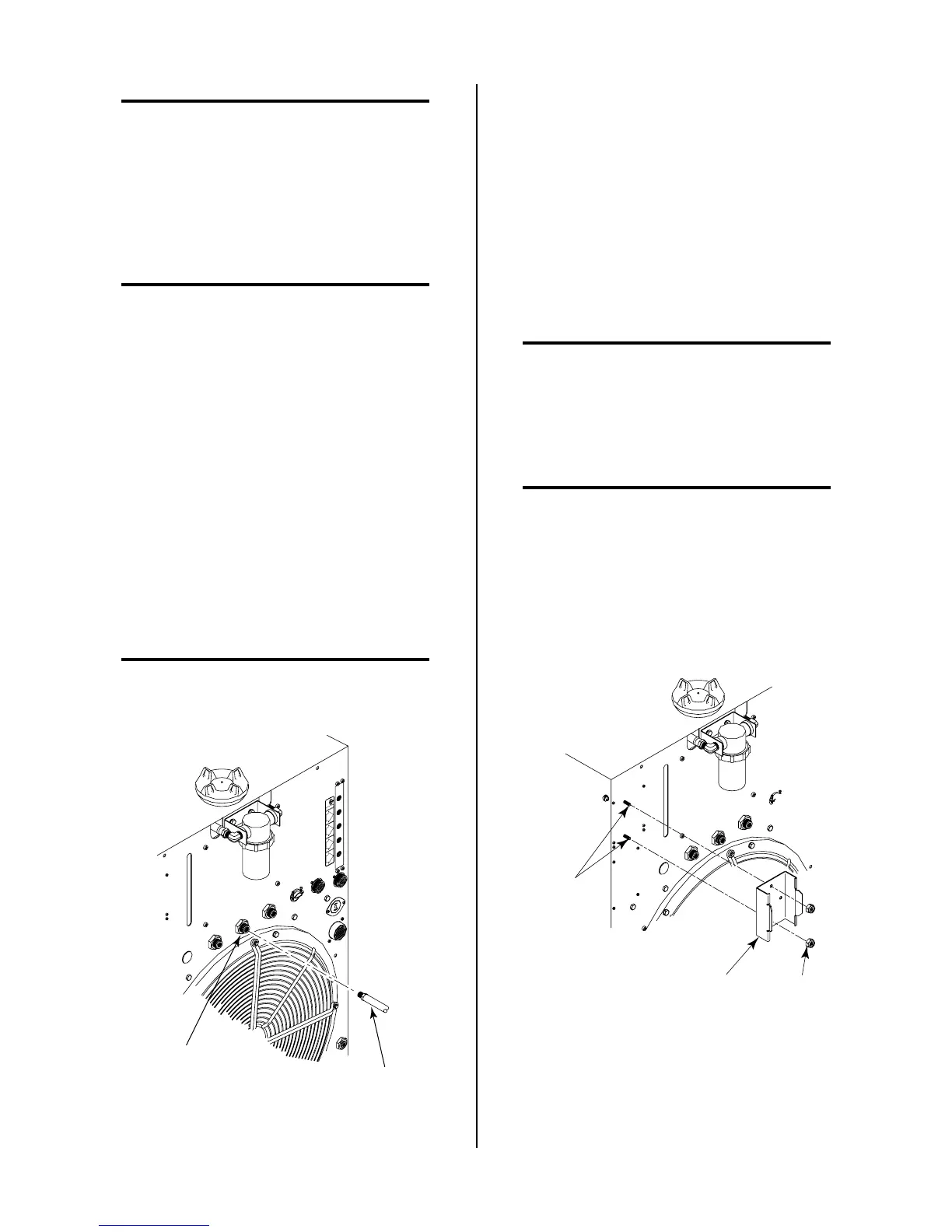

OUTPUT

TO

CONTROL

MODULEMODULE

AIR

PLASMAPLASMA

INPUTINPUT

N

2

PLASMAPLASMA

INPUTINPUT

O

2

PLASMAPLASMA

INPUTINPUT

PLASMA GASPLASMA GAS

Ar/H

2

PLASMAPLASMA

INPUTINPUT

Water Secondary

Hose From Supply

Secondary Water

Fitting

A-01504

Figure 3-11 Secondary Water Connection

4. Set the SECONDARY selector switch on the front

panel of the Power Supply to the WATER posi-

tion.

D. Plasma and Secondary Gases With

Optional Gas Control

The required plasma and secondary gases are connected

to the rear of the Power Supply. The secondary selection

switch on the front panel of the Power Supply must al-

ways be set to GAS for all secondary gases when the Gas

Control Option is installed. The type of gas to be used

will be selected at the Gas Control Option front panel.

NOTE

If compressor shop air is to be used as the plasma

gas the line must be filtered.

If using shop air as one of the plasma gases then install

the optional Two Stage Air Line Filter per the following

procedure:

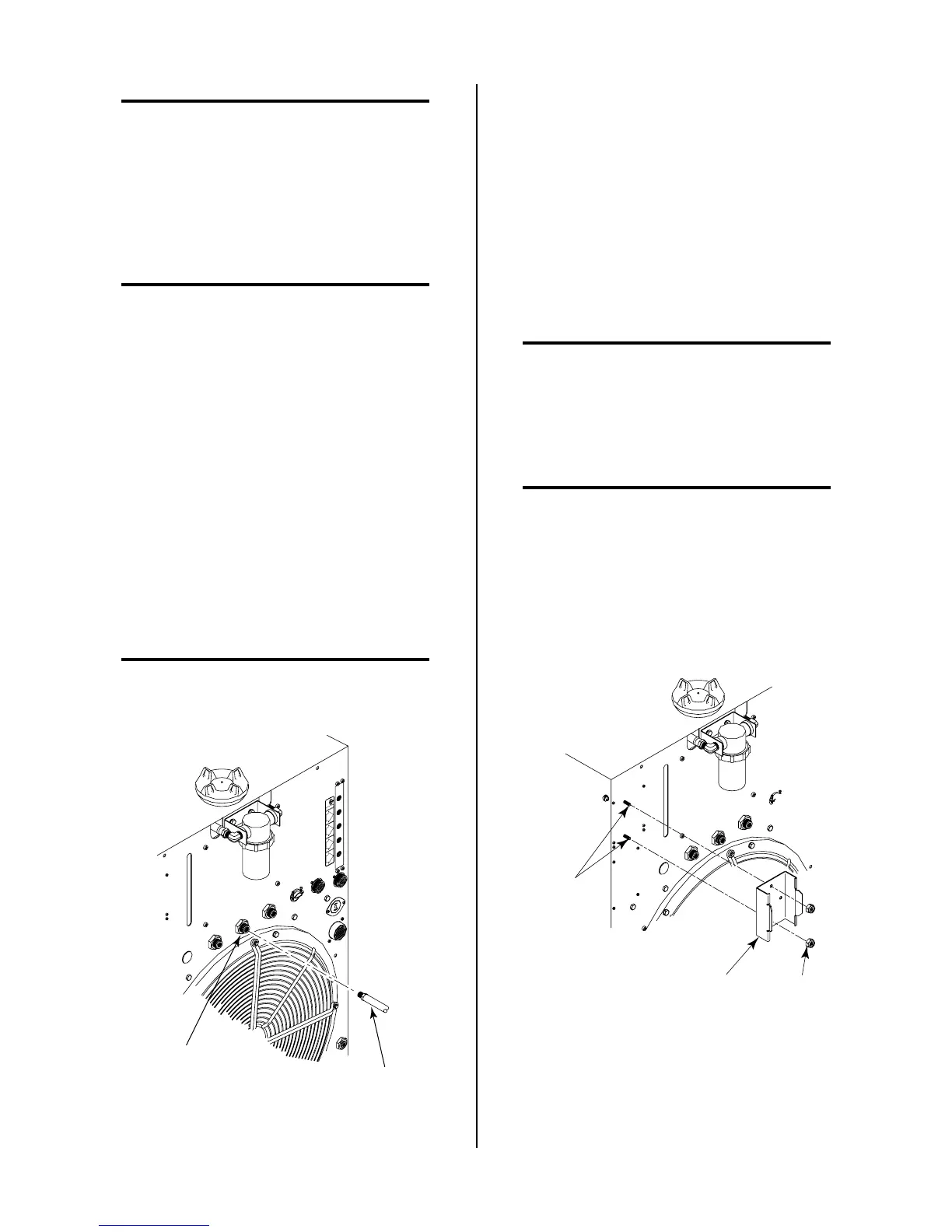

NOTE

Use these instructions only for Power Supplies that

HAVE the Gas Control Option installed.

1. Remove the air supply input hose from the Plasma

Gas (Air) Input Fitting at the rear of the power sup-

ply, if already installed.

2. Locate the two mounting studs on the rear of the unit

and secure the Air Filter Mounting Bracket to the panel

using the two 10-32 Nylon Locking Nuts provided.

Air Filter

Mounting Bracket

Mounting

Nuts

Mounting

Studs

A-01336

Figure 3-12 Air Filter Mounting Bracket Installation

3. Place thread sealer on the threads of the 1/4 NPT Street

Elbow (see NOTE).

Loading...

Loading...