Troubleshooting

Motorgrader System Five Operator’s Manual

7-14

NOTICE

NOTICE

If you go past the chisel mark, repeat the procedure

beginning with the blade rotated 1 foot clockwise beyond

the chisel mark.

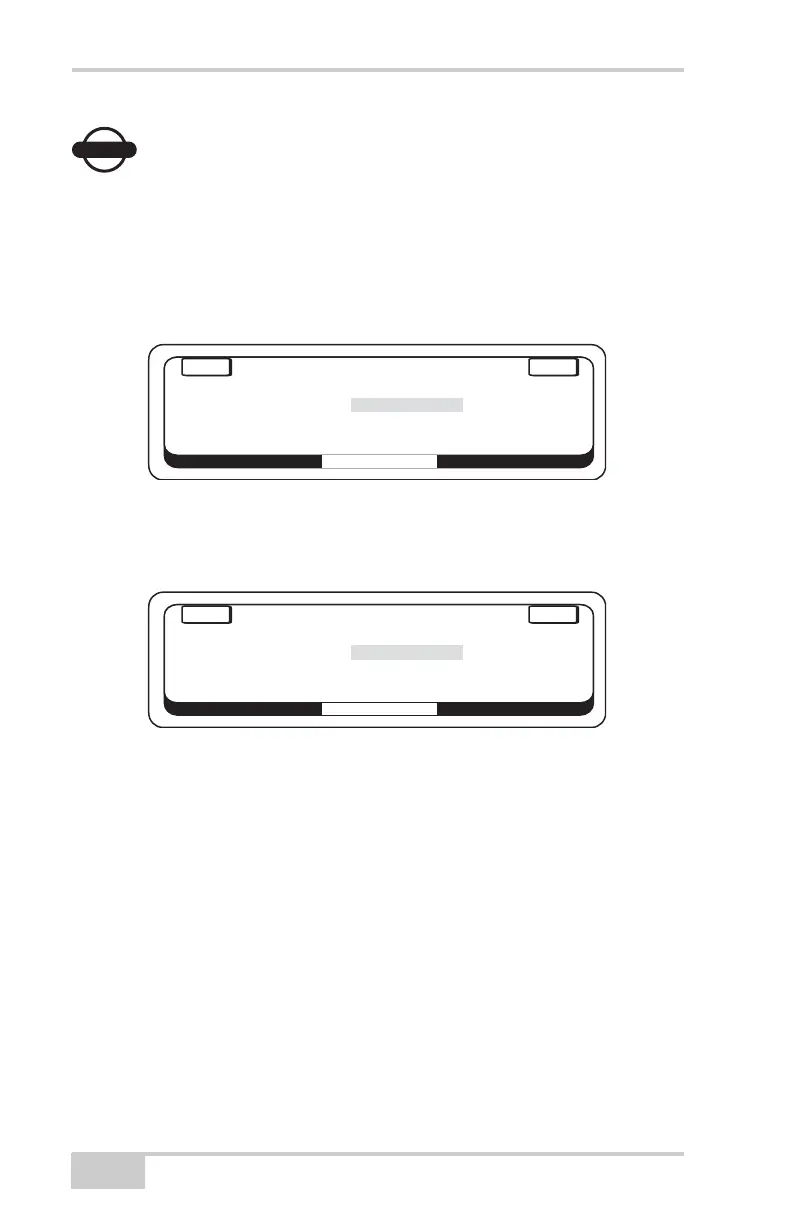

If the value is within 1 or 2 degrees of 0, then rotation is accurately

compensated and no repairs are needed!

Figure 7-18.

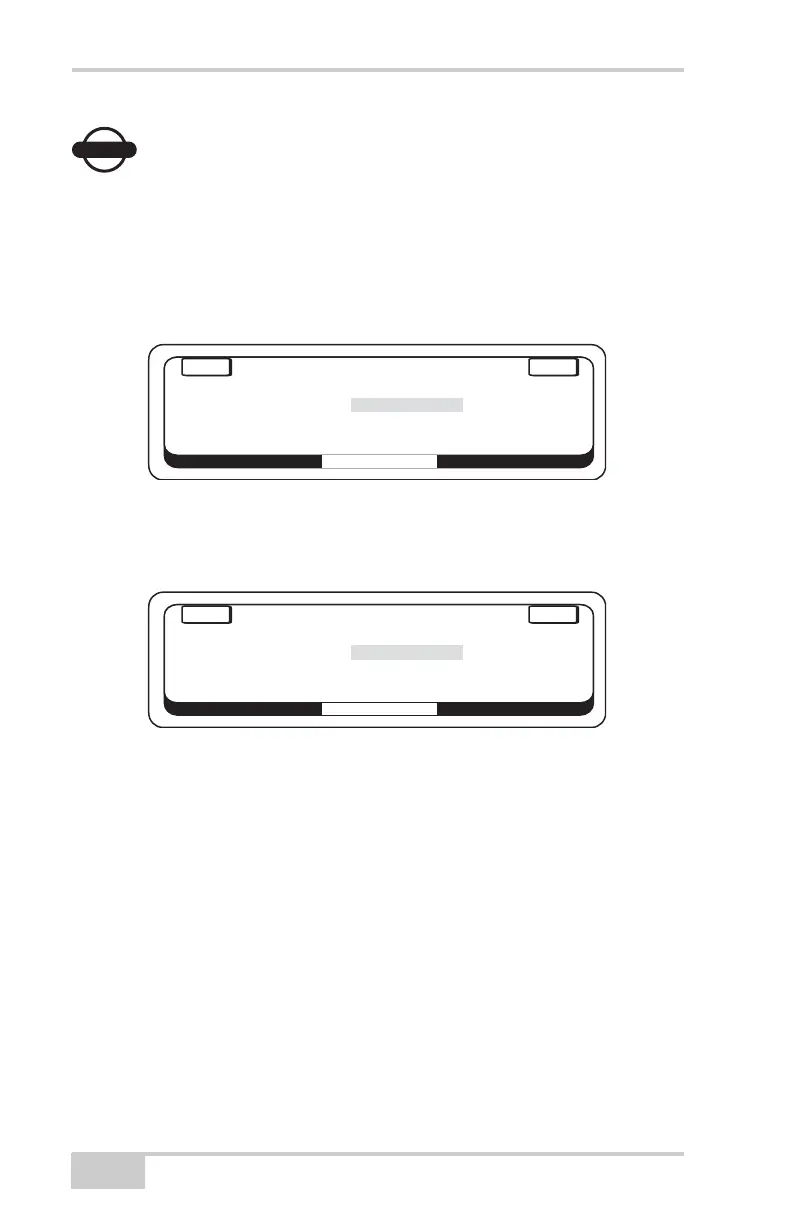

If the value is more than beyond 2 degrees, then the problem is one or

more of the following:

Figure 7-19.

• Excess "slop" in the pin between the grader's hydraulic swivel

and the hose tray.

• Hose tray is bent and the guide rods are no longer attached to the

circle.

• The hole where guide rod is attached to circle is worn so the

guide rod is no longer held tight.

• Guide rods are weak and have too much flex.

These are physical wear areas that must be repaired for System Five

to cut accurate cross slope.

E

NT

E

R

E

XIT

KNOB

VALVE

LASER

SONIC

KNOB

VALVE

LASER

SONIC

SYSTEM TEST

MAINFALL

ROTATION 2°

SLOPE

E

NT

E

R

E

XIT

KNOB

VALVE

LASER

SONIC

KNOB

VALVE

LASER

SONIC

SYSTEM TEST

MAINFALL

ROTATION 5°

SLOPE

Loading...

Loading...