Setup

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

1

InstallingtheAnti-Siphon

FillReceptacle

Partsneededforthisprocedure:

1

90°tting

1

Quickcoupler

1Hoseadapter

1Fill-receptaclebracket

1

Flange-headbolt(5/16x3/4inch)

1Anti-siphonhose

Procedure

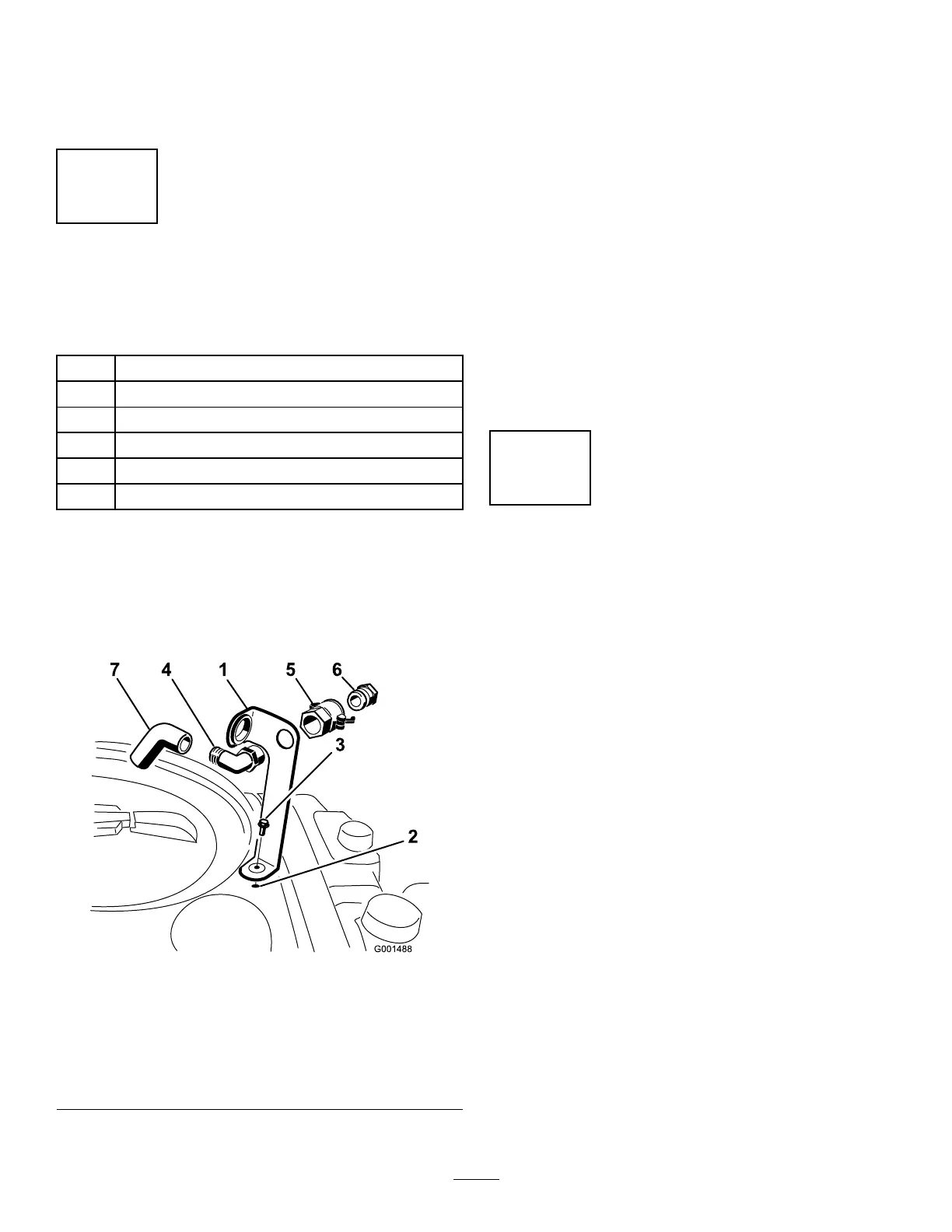

1.Placethell-receptaclebracketoverthe

threadedholeinthetankandsecureitwitha

ange-headbolt(5/16x3/4inch)asshownin

Figure3.

g001488

Figure3

1.Fill-receptaclebracket

5.Quickcoupler

2.Threadedholeinthetank6.Hoseadapter

3.Flangebolt(5/16x3/4

inch)

7.Anti-siphonhose

4.90°elbowtting

2.Placethethreadedendofthe90°elbowtting

throughthebracketandthreadthequickcoupler

ontoit,securingittothebracket(Figure3).

Note:Installthettingwiththeopenend

pointingtowardthelargeopeninginthebracket

andtowardthetankopeningsothatthewater

arcsintothetankwhenyoullit.

3.Installthehoseadapterintothequickcoupler

(Figure3).

4.Locktheadapterintoplacebyswingingthe

leverstowardtheadapterandthensecurethem

withthehairpincotters(Figure3).

5.Installtheanti-siphonhosethroughthelarge

openingonthebracketandontothebarbedend

ofthe90°elbowtting(Figure3).

Important:Donotlengthenthehoseto

allowcontactwiththetankuids.

2

CheckingtheSection-Hinge

Springs

NoPartsRequired

Procedure

Important:Operatingthespraysystemwith

thesection-hingespringsundertheincorrect

compressioncoulddamagetheboomassembly.

Measurethespringsandusethejamnutto

compressthespringsto3.96cm(1.56inches)if

necessary.

Thesprayerisshippedwiththesectionextensions

swungforwardtofacilitateshippingthemachine.

Thespringsarenotfullytightenedatthetimeof

manufacturetoallowthesectionstobeinthisposition

fortransit.Beforeoperatingthemachine,thesprings

mustbeadjustedtothecorrectcompression.

1.Ifnecessary,removethepackingcomponents

thatsecuretherightandleftextensionsections

duringshipping.

2.Supportthesectionswhiletheyareextendedto

thesprayposition.

3.Atthesectionhinge,measurethecompression

oftheupperandlowerspringswhilethesections

areintheirextendedposition(Figure4).

14

Loading...

Loading...