6.Turntheeyeletrodintheactuatorrodtoshorten

orlengthentheextendedactuatortothedesired

position(Figure59).

Note:Youmustturntheeyeletrodinhalfor

completerevolutionssothatyoucanassemble

therodtotheboom.

7.Oncethedesiredpositionhasbeenachieved,

tightenthejamnuttosecuretheactuatorand

eyeletrod.

8.Raisetheboomtoalignthepivotwiththe

actuatorrod.

9.Whileholdingtheboom,insertthepinthrough

bothboompivotandactuatorrod(Figure58).

10.Withthepininplace,releasetheboomand

securethepinwiththecotterpreviously

removed.

11.Repeattheprocedureforeachactuatorrod

bearing,ifnecessary.

Cleaning

CleaningtheFlowMeter

ServiceInterval:Every200hours/Yearly(whichever

comesrst)(moreoftenwhenusing

wettablepowders).

1.Thoroughlyrinseanddraintheentirespraying

system.

2.Removetheowmeterfromthesprayerand

ushitwithcleanwater.

3.Removetheretainerringontheupstreamside

(Figure60).

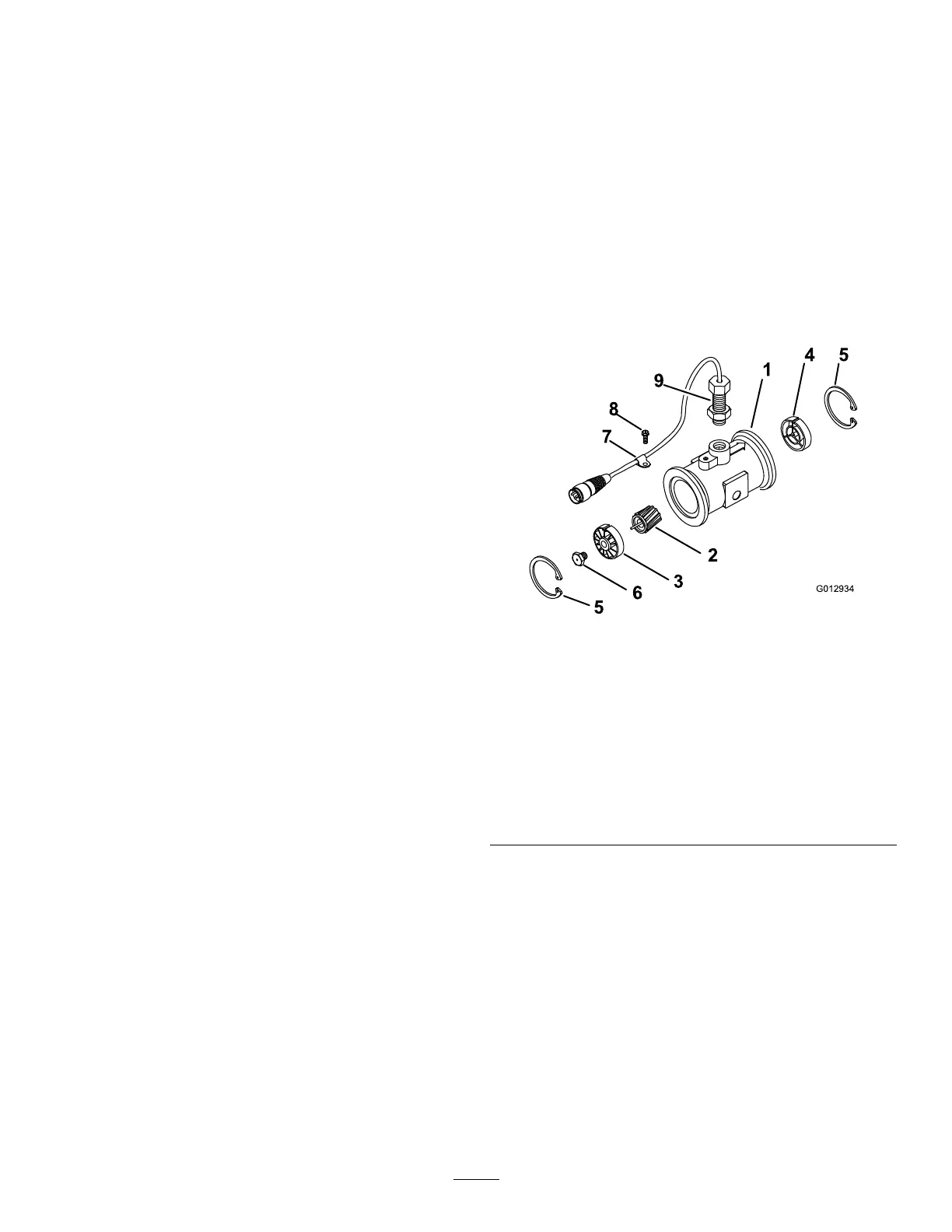

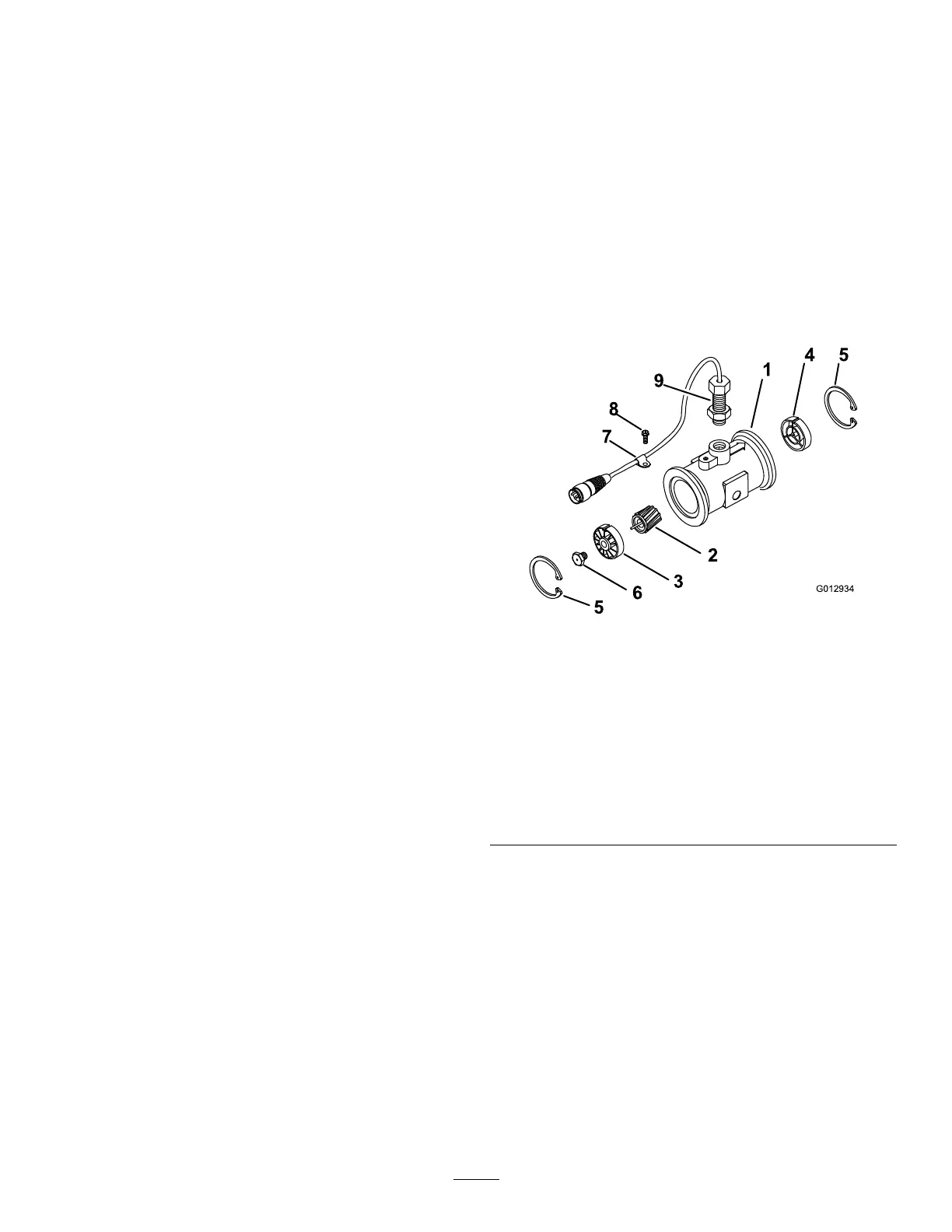

g012934

Figure60

1.Flange(ow-meterbody)

7.Upstreamhubandbearing

(withkeywayup)

2.Downstreamhub(with

keywayup)

8.Turbinestud

3.Retainingring9.Wire-harnessclamp

4.Downstreamarrow

(ow-meterbody)

10.Flange-headscrew

5.Upstream

11.Sensorassembly

6.Rotor/magnet

4.Cleantheturbineandtheturbinehubtoremove

metallingsandanywettablepowders.

5.Inspecttheturbinebladesforwear.

Note:Holdtheturbineinyourhandandspin

it.Itshouldspinfreelywithverylittledrag.Ifit

doesnot,replaceit.

6.Assembletheowmeter.

7.Usealowpressure(50kPaor5psi)airjetto

ensurethattheturbinespinsfreely.

Note:Iftheturbinedoesnotspinfreely,loosen

thehexstudonthebottomoftheturbinehubby

1/16ofaturnuntilitdoesspinsfreely.

57

Loading...

Loading...