Pre-Maintenance

Procedures

RaisingtheSprayer

Whenevertheengineisrunforroutinemaintenance

and/orenginediagnostics,therearwheelsofthe

sprayershouldbe2.5cm(1inch)offthegroundwith

therearaxlesupportedonjackstands.

DANGER

Asprayeronajackmaybeunstableandslip

offthejack,injuringanyonebeneathit.

•Donotstarttheenginewhilethesprayer

isonajack.

•Alwaysremovethekeyfromtheignition

beforegettingoffthesprayer.

•Blockthetireswhenthesprayerisona

jack.

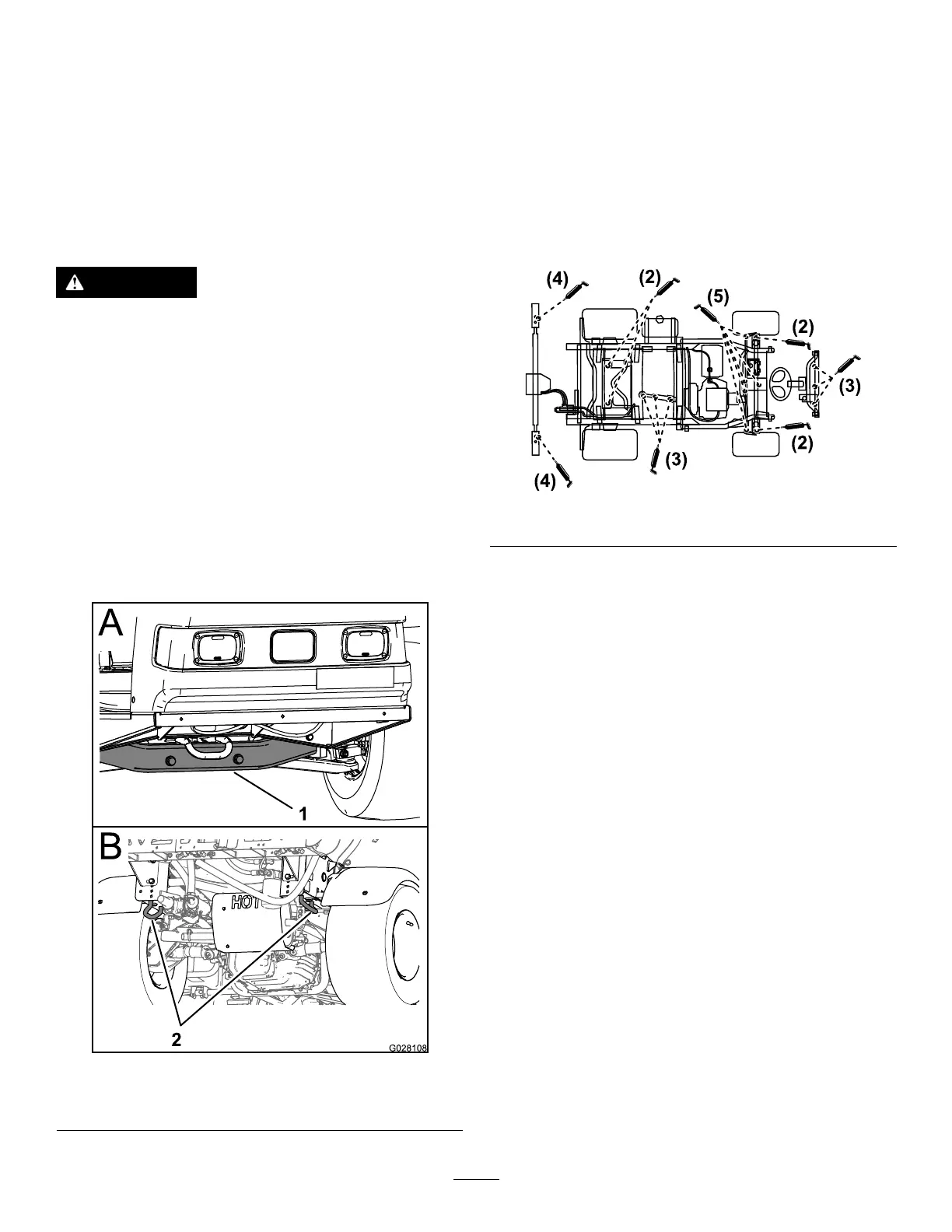

Thejackingpointatthefrontofthesprayerisunder

thefrontcrossbar(Figure30A).Thejackingpointat

therearofthesprayerisontherearframesupport,

behindthereartie-downloops(Figure30B).

g028108

Figure30

1.Frontjackingpoint2.Reartie-downloops

Lubrication

GreasingtheMachine

ServiceInterval:Every100hours/Yearly(whichever

comesrst)—Lubricateallgrease

ttings.

GreaseType:No.2lithiumgrease

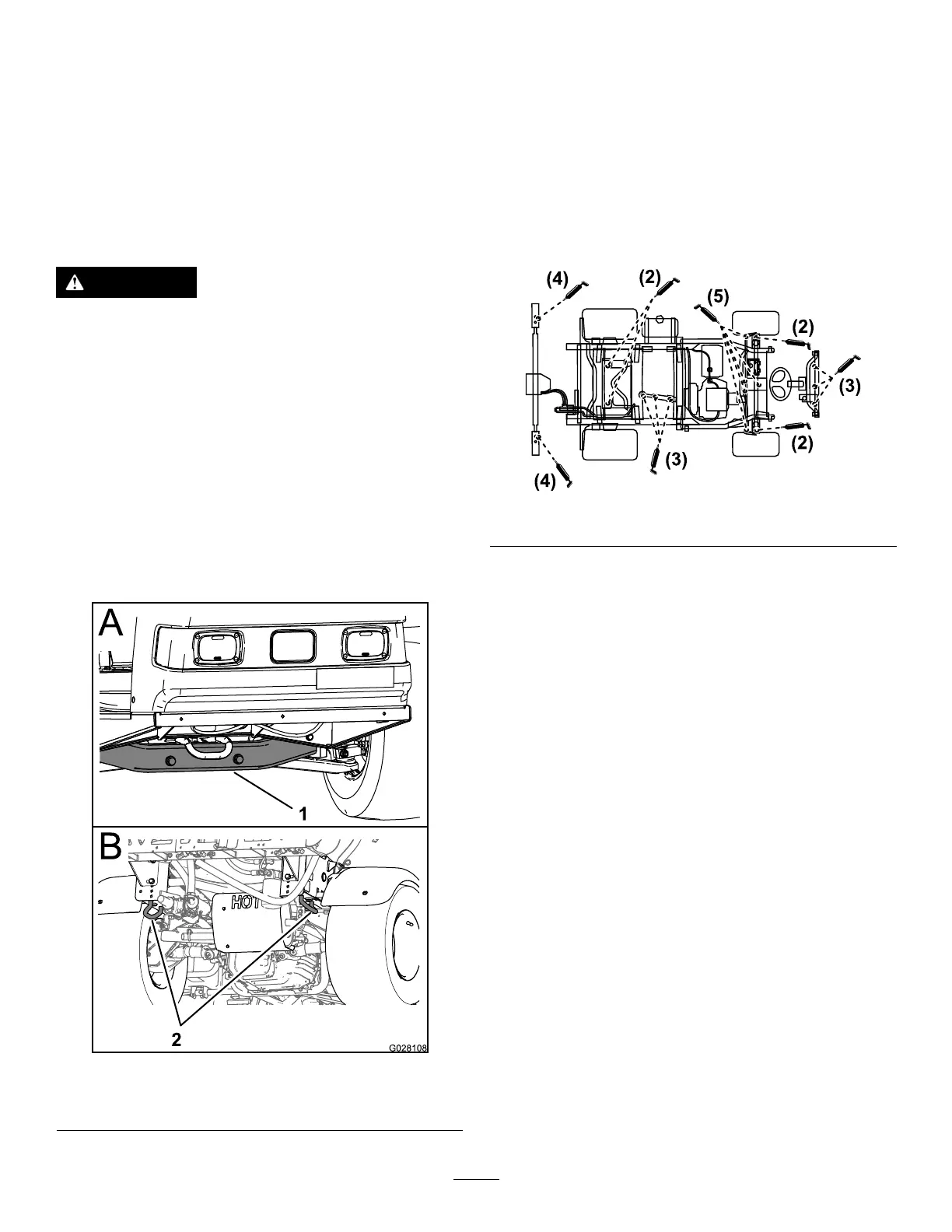

ReferFigure31forthegrease-pointlocations.

g216476

Figure31

1.Wipethegreasettingcleansothatyoudonot

forcedirtordebrisintothebearingorbushing.

2.Pumpgreaseintothebearingorbushing.

3.Wipeofftheexcessgrease.

GreasingtheSprayerPump

ServiceInterval:Every50hours—Lubricatethe

pump.

GreaseType:MobilXHP461

1.Raisethesprayer;refertoRaisingtheSprayer

(page40).

2.Locatethesprayerpump.

Note:Thepumpislocatedbelowtheseat;refer

toLocatingtheSprayPump(page33).

3.Wipethe2remotegreasettingsclean(Figure

32AandFigure32B).

40

Loading...

Loading...