Maintenance

Note:Downloadafreecopyoftheschematicbyvisitingwww.Toro.comandsearchingforyourmachine

fromtheManualslinkonthehomepage.

Foradditionalinformationaboutthesprayersystem,refertothesprayersystemschematicinSchematics

(page72).

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

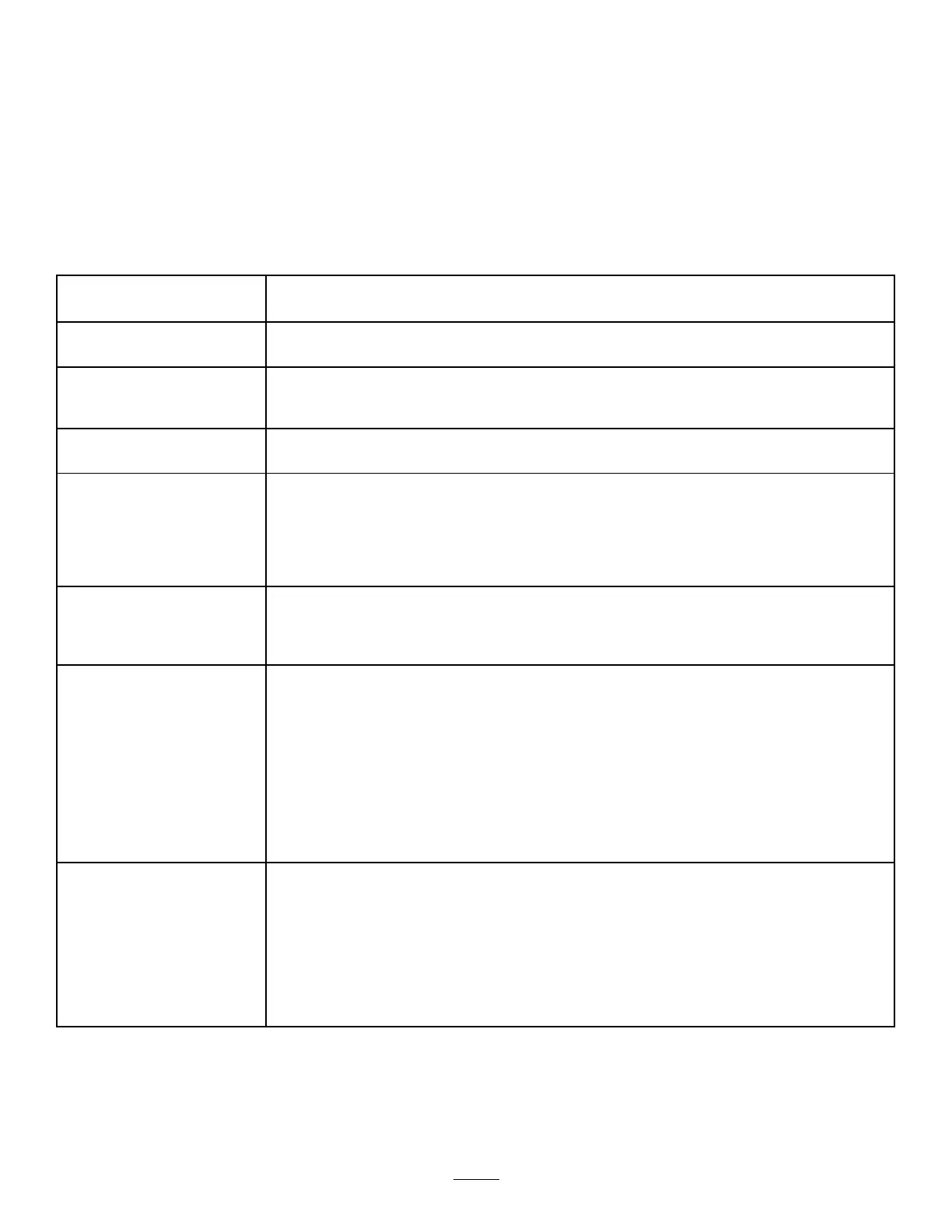

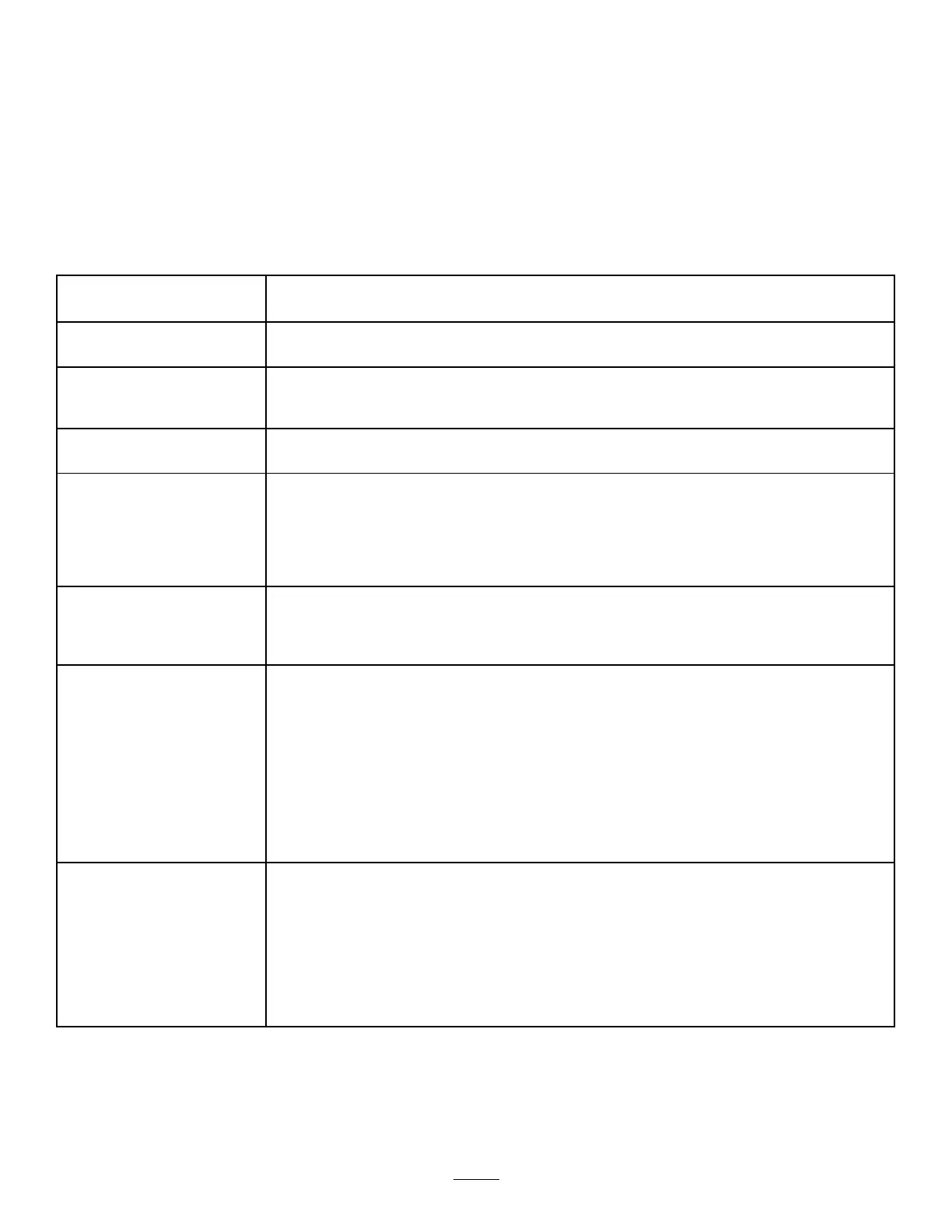

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Aftertherst8hours

•Torquethewheel-lugnuts.

•Replacethehydrauliclter.

Aftertherst50hours

•Changetheengineoil.

•Checktheairlterforthecarboncanister.

•Replacethecarbon-canisterlter.

Aftertherst100hours

•Toprovideproperperformanceandlongsprayerlife,followtheseguidelinesfor

therst100operatinghours:

Beforeeachuseordaily

•Cleanthesuctionlter.

•Cleanthepressurelter.

•Checkthetankstraps.

•Checktheengine-rotatingscreen.

•Checktheengineoil.

•Checkthetirepressure.

Every50hours

•Lubricatethepump.

•Cleanandoiltheair-cleanerfoamelement(moreoftenindusty,dirtyconditions).

•Checkthebattery-cableconnections.

•Checkthebattery-electrolytelevel.

Every100hours

•Lubricateallgreasettings.

•Lubricatethesectionhinges.

•Cleantheengine-rotatingscreen(moreoftenindusty,dirtyconditions).

•Changetheengineoil(moreoftenwhenoperatingunderheavyloadorinhigh

temperature).

•Replacetheengine-oillter.

•Replacethefuellter.

•Torquethewheel-lugnuts.

•Inspecttheconditionandwearofthetires.

•Checkfrontwheeltoe-in.

•Inspectthebrakes.

Every200hours

•Replacetheair-cleanerpaperelement(moreoftenindusty,dirtyconditions).

•Changethesparkplugs.

•Checktheairlterforthecarboncanister.

•Replacethecarbon-canisterlter.

•Checktheadjustmentofthedifferential-lockcable.

•Checktheparkingbrake.

•Checkthetransaxle/hydraulicuid.

•Inspectallhosesandconnectionsfordamageandproperattachment.

•Cleantheowmeter(moreoftenwhenusingwettablepowders).

37

Loading...

Loading...