Note:Ensurethatthelterelementisrmly

seatedintothelterhead.

8.Installthebowlontothelterheadandtighten

byhand(Figure55).

9.Installtheplugintothebowlandtightenbyhand

(Figure55).

ChangingtheNozzleFilter

Note:Determinetheappropriatenozzleltermesh

sizethatyouneedforyourjob;refertoSelectinga

Nozzle-TipFilter(Optional)(page36).

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,shutoffthesprayerpump,shut

offtheengine,andremovethekey.

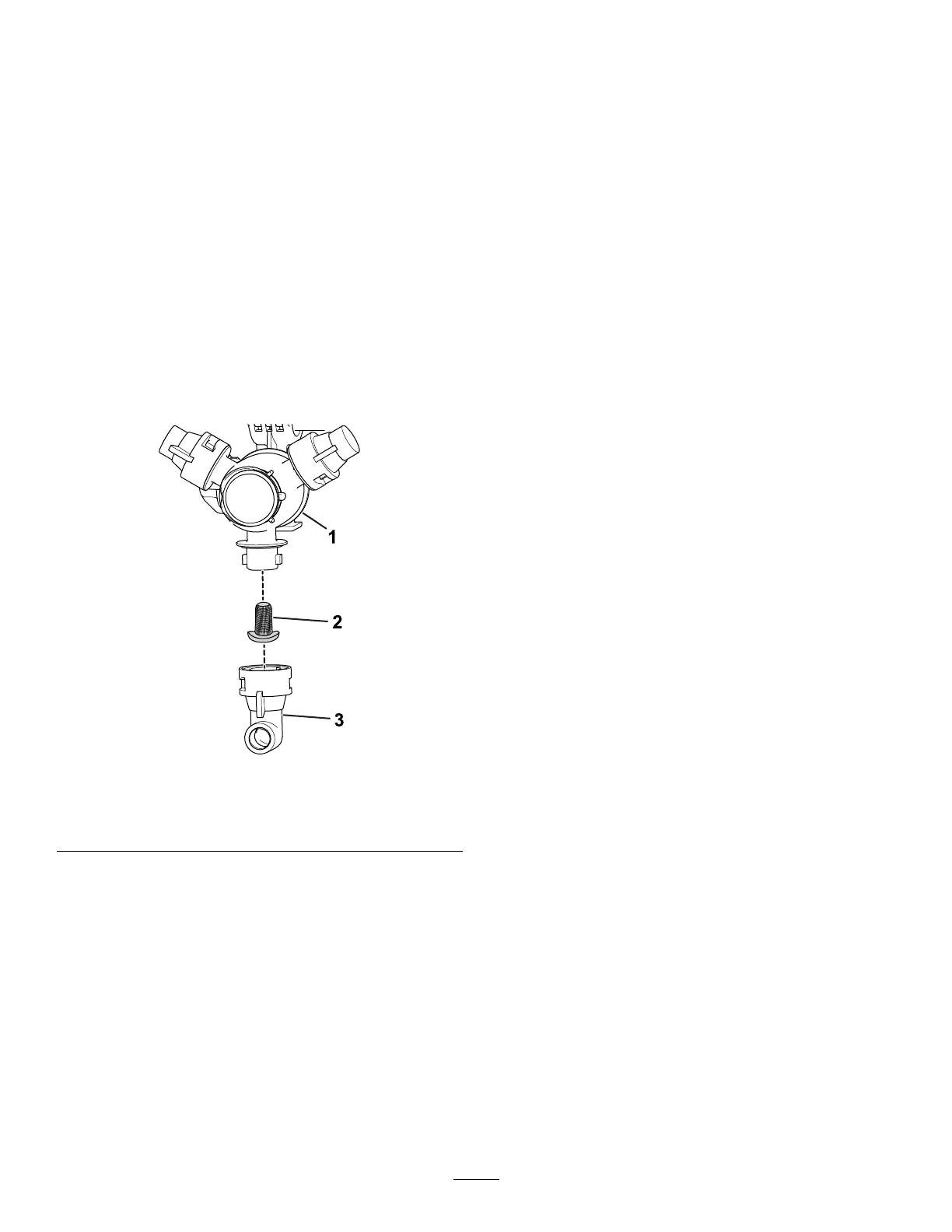

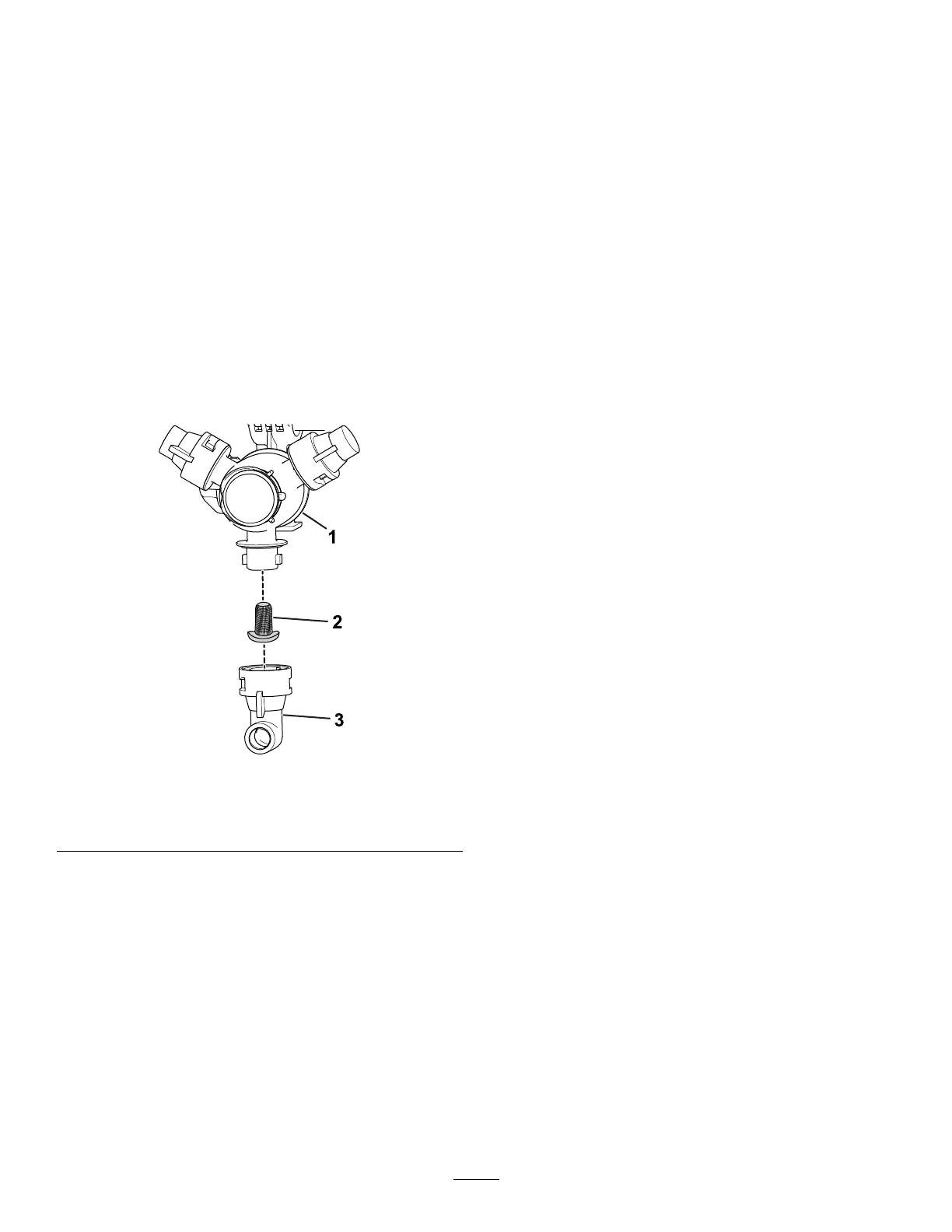

2.Removethenozzlefromthesprayturret(Figure

56).

g209504

Figure56

1.Sprayturret

3.Nozzle

2.Nozzlelter

3.Removetheoldnozzlelter(Figure56).

Note:Discardtheoldlter.

4.Installthenewnozzlelter(Figure56).

Note:Ensurethatthelterisfullyseated.

5.Installthenozzleontothesprayturret(Figure

56).

InspectingthePump

ServiceInterval:Every400hours/Yearly(whichever

comesrst)—Inspectthepump

diaphragmsandreplaceif

necessary(seeanAuthorized

ToroServiceDistributor).

Every400hours/Yearly(whichevercomes

rst)—Inspectthepumpcheckvalvesand

replaceifnecessary(seeanAuthorizedT oro

ServiceDistributor).

Note:Thefollowingmachinecomponentsare

consideredpartssubjecttoconsumptionthroughuse

unlessfounddefectiveandarenotcoveredbythe

warrantyassociatedwiththismachine.

HaveanAuthorizedT oroServiceDistributorcheck

followinginternalpumpcomponentsfordamage:

•Pumpdiaphragms

•Pumpcheckvalvesassemblies

Replaceanycomponents,ifnecessary.

InspectingtheNylonPivot

Bushings

ServiceInterval:Every400hours/Yearly(whichever

comesrst)

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,shutoffthepump,shutoffthe

engine,andremovethekey.

2.Extendtheouter-boomsectionstothespray

positionandsupporttheboomsusingstandsor

strapsandliftingequipment.

3.Withtheweightoftheboomsupported,remove

theboltandnutsecuringthepivotpintothe

boomassembly(Figure57).

55

Loading...

Loading...