5.Removethedrainplugfromthedrainportby

rotatingtheplugcounterclockwiseandremoving

itfromthetransmission(Figure59).

Note:Allowthetransmissionuidtodrain

completely.

6.Installthedrainplug(Figure59).

7.Add700ml(23.7oz)ofDexronVItransmission

uidintothetransmissionthroughthellport

(Figure58).

Note:Useafunnelwithaexiblehosewhen

llingthetransmission.

Note:Whenthetransmissionuidlevelis

correct,theuidshouldbelevelwiththebottom

ofthethreadsinthellport.

8.Installthellplug(Figure58).

ServicingtheReservoirofthe

Speed-ControlCylinder

ServiceInterval:Every200hours

Reservoir-uidtype:DOT3brakeuid

1.Removetheknobsfromthehydraulic-liftlever

andthespeed-rangelever(Figure60).

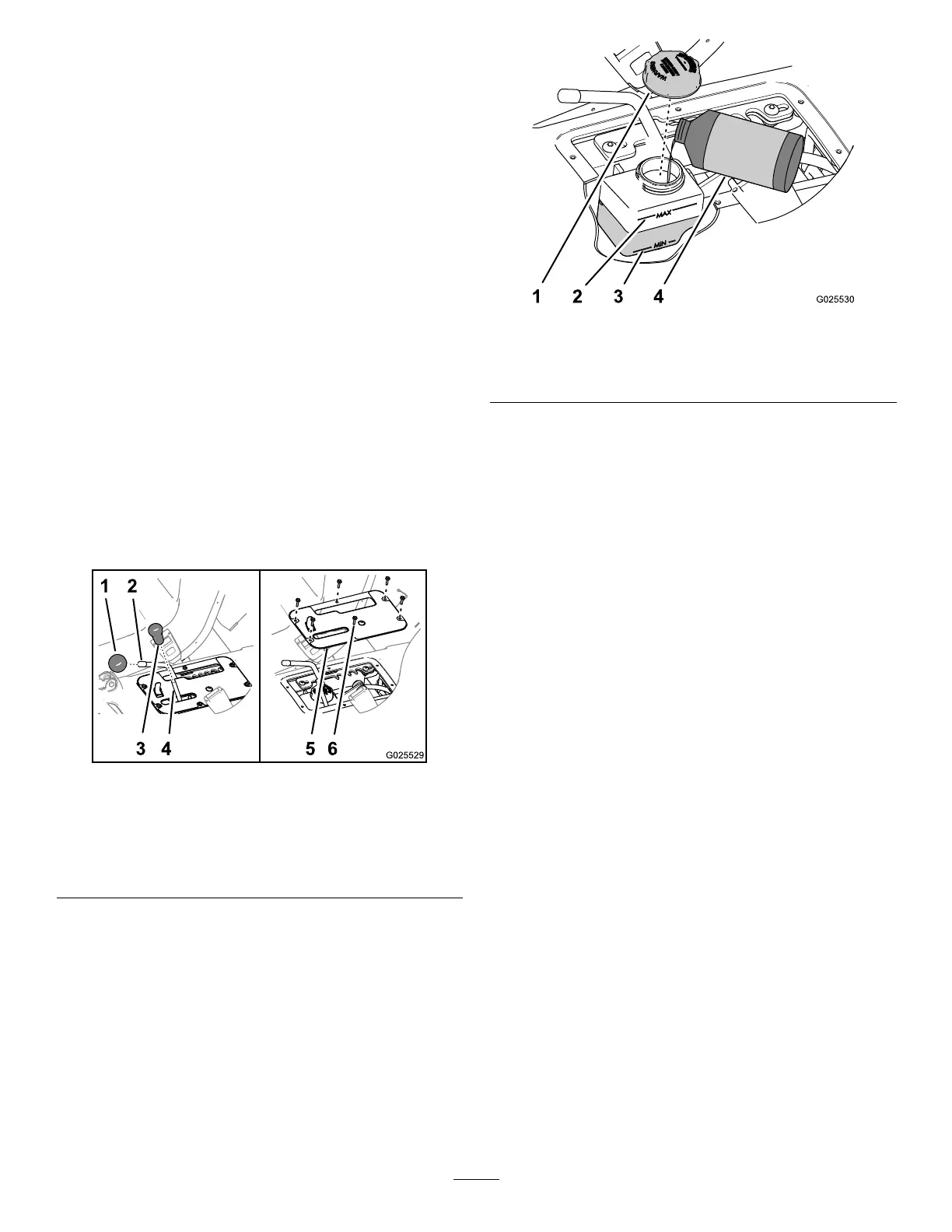

g025529

Figure60

1.Knob(speed-rangelever)4.Rod(hydraulic-liftlever)

2.Rod(speed-rangelever)5.Control-coverplate

3.Knob(hydraulic-liftlever)6.Hex-washerscrews(#10

x3/4inch)

2.Removethe6hex-washerscrews(#10x3/4

inch)thatsecurethecontrol-coverplatetothe

seatbase,andremovethecoverplate(Figure

60).

3.Movethespeed-rangelevertotheTRANSPORT

position;refertoUsingtheSpeed-Range

Control(page27).

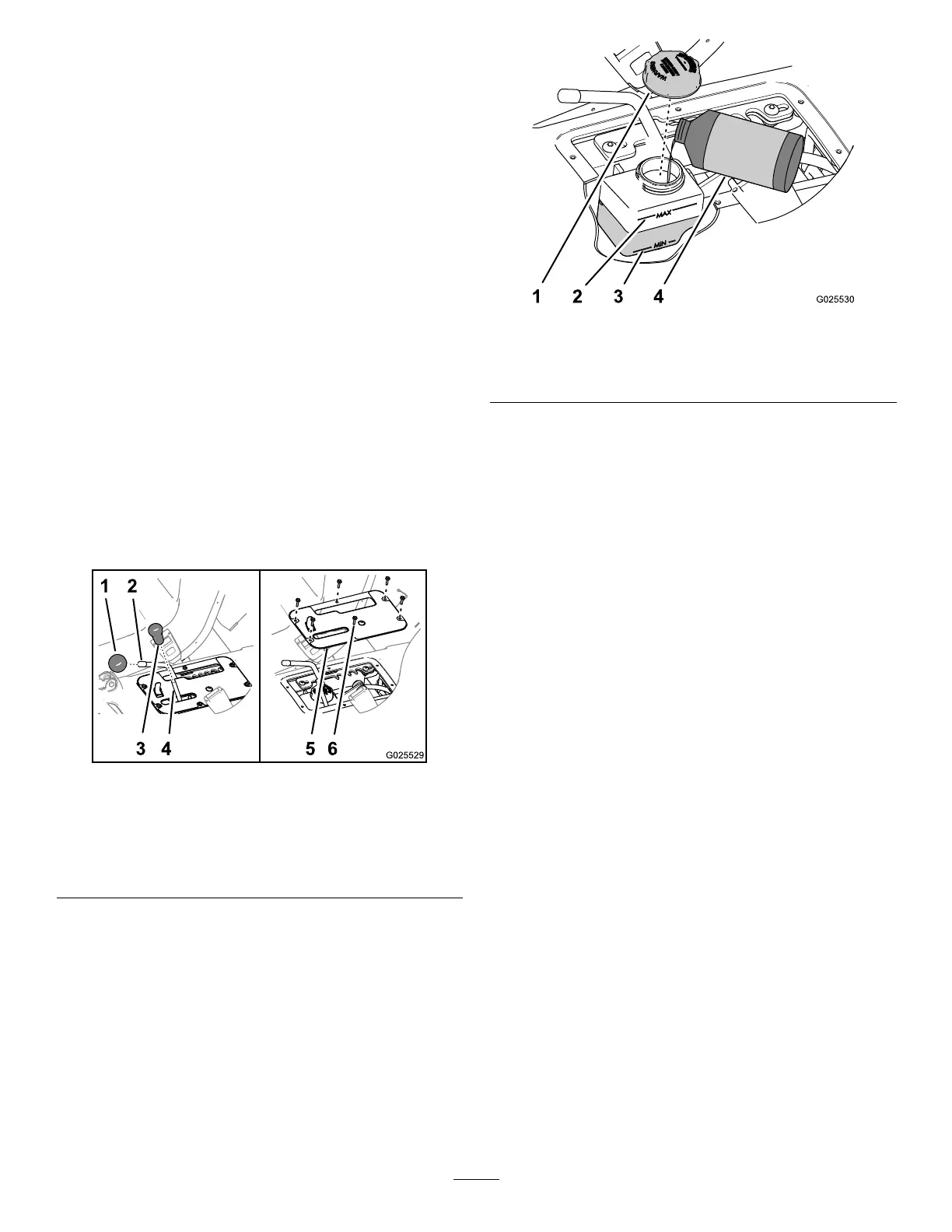

4.Checktheuidlevelinthereservoirforthe

speed-controlcylinder(Figure61).

Note:ThenormaluidlevelisbetweentheMin

andMaxmarksonthesideofthereservoir.

g025530

Figure61

1.Cap3.Minmark(reservoir)

2.Maxmark(reservoir)4.DOT3brakeuid

5.Iftheuidlevelislow,performthefollowing:

A.Wipecleantheareaaroundthecapforthe

reservoir(Figure61).

B.Removethecapfromthereservoir(Figure

61).

C.Addthespecieduidtoraisethelevel

midwaybetweentheMinandMaxmarkson

thesideofthereservoir(Figure61).

D.Installthecaphandtight(Figure61).

6.Aligntheholesinthecontrol-coverplatetothe

holesintheseatbase(Figure60).

7.Securetheplatetothebasewiththe6

hex-washerscrews(Figure60)thatyou

removedinstep2.

8.Threadtheknobsontotherodsforthe

hydraulic-liftleverandthespeed-rangelever

(Figure60).

AdjustingtheSpeedControl

Important:Theminimumcontrolledspeedfor

themachineis4.0kph(2.5mph)atfullengine

speed.Controllingthemachinespeedslowerthat

4.0kph(2.5mph)resultsinexcessivebeltand

clutchwear.

1.DrivethemachineinspeedrangeA(lowrange),

B(mid-lowrange),C(mid-highrange),orD

(highrange)inordertodeterminewhichspeed

rangeincludesthemaximumgroundspeedthat

youwanttoset;refertoUsingtheSpeed-Range

Control(page27).

Note:Usethespeedometertodeterminethe

speedthatthemachineistraveling.

2.Removetheknobsfromthehydraulic-liftlever

andthespeed-rangelever(Figure60).

50

Loading...

Loading...