Installation, Operation and Maintenance 8 - 1

3HULRGLF0DLQWHQDQFH

Overview

This section describes preventive maintenance

procedures and intervals for the Series R unit. Use a

periodic maintenance program to ensure maximum

performance and efficiency of the Series R units.

An important aspect of the chiller maintenance

program is the regular completion of the “Series R

Operating Log”; an example of this log is provided in

this manual. When filled out properly the completed

logs can be reviewed to identify any developing

trends in the chiller's operating conditions.

For example, if the machine operator notices a

gradual increase in condensing pressure during a

month's time, he can systematically check--then

correct--the possible cause(s) of this condition (e.g.,

fouled condenser tubes, non-condensables in the

system).

Weekly Maintenance and Checks

After the unit has operated for approximately 30

minutes and the system has stabilized, check the

operating conditions and complete the procedures

below:

q Log the chiller.

q Check evaporator and condenser pressures with

gauges and compare to the reading on the Clear

Language Display. Pressure readings should fall

within the following ranges specified in the

Operating Conditions table:

NOTE: Optimum condenser pressure is dependent

on condenser water temperature, and should equal

the saturation pressure of the refrigerant at a

temperature 2 to 5

°

F above that of leaving condenser

water at full load.

M o n t h l y M a i nt e n a n c e a n d C h e c k s

q Review operating log.

q Clean all water strainers in both the chilled and

condensing water piping systems.

q Measure the oil filter pressure drop. Replace oil

filter if required. Refer to “Service Procedures”.

q Measure and log the subcooling and superheat.

Refer to

Table 26

q If operating conditions indicate a refrigerant

shortage, leak check the unit using soap bubbles.

q Repair all leaks.

q Trim refrigerant charge until the unit operates in

the conditions listed in

Table 26

at full load, ARI

conditions.

NOTE: ARI conditions are: condenser water: 85

°

F

and 3 GPM/XXX tons and evaporator water: 54-44

°

F

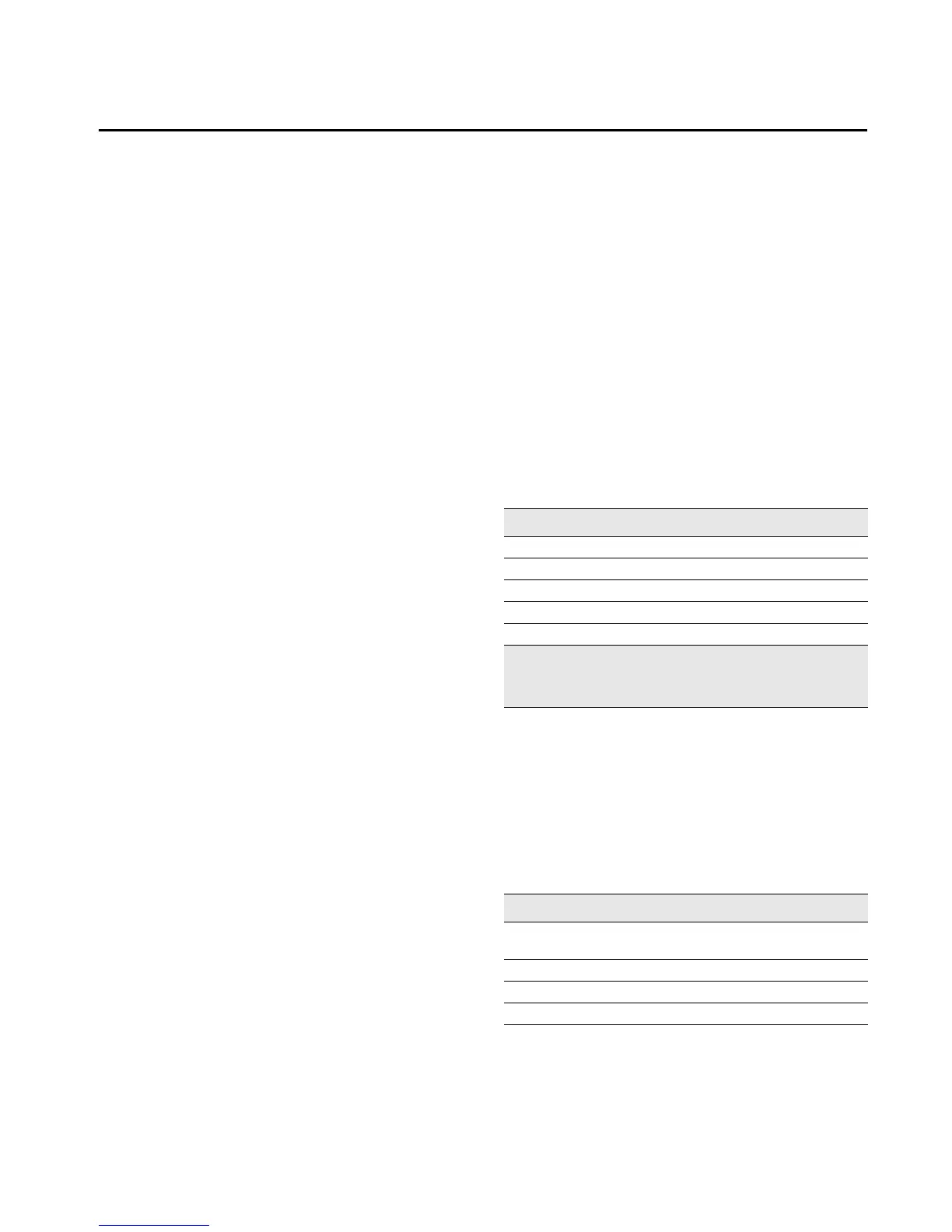

Table 26

Operating Conditions at Full Load

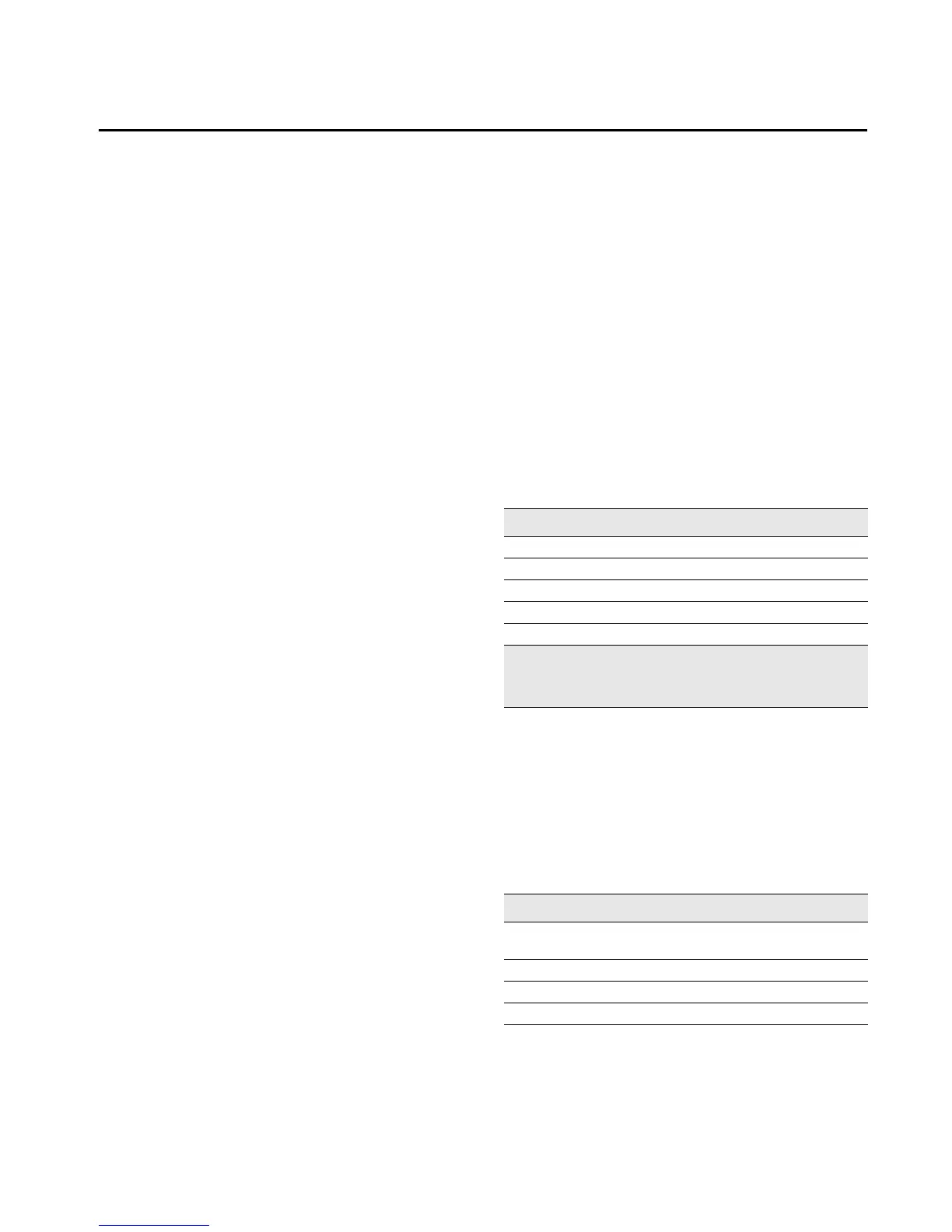

q If full load conditions can not be met, use

Table 27

, to trim the refrigerant charge

NOTE: Conditions at minimum must be: entering

condenser water: 85

°

F and entering evaporator

water: 55

°

F

Table 27

Operating Conditions at Minimum Load

NOTE: * 1.0

°

F for new unit.

Description Condition

Evaporator pressure 40-55 psig

Condensing pressure 85-120 psig

Discharge superheat 17

°

F

Subcooling 5-10

°

F

EXV percent open 40-50% open in Auto mode

NOTE: All conditions stated above are based on

the unit running fully loaded, running at ARI

conditions.

Description Condition

Evaporator approach *less than 7

°

F (non-glycol

applications)

Condensing approach *less than 7

°

F

Subcooling 2-3

°

F

EXV percent open 10-20 % open

Loading...

Loading...