Installation, Operation and Maintenance 2 - 25

Water Pressure Gauges and

Thermometers

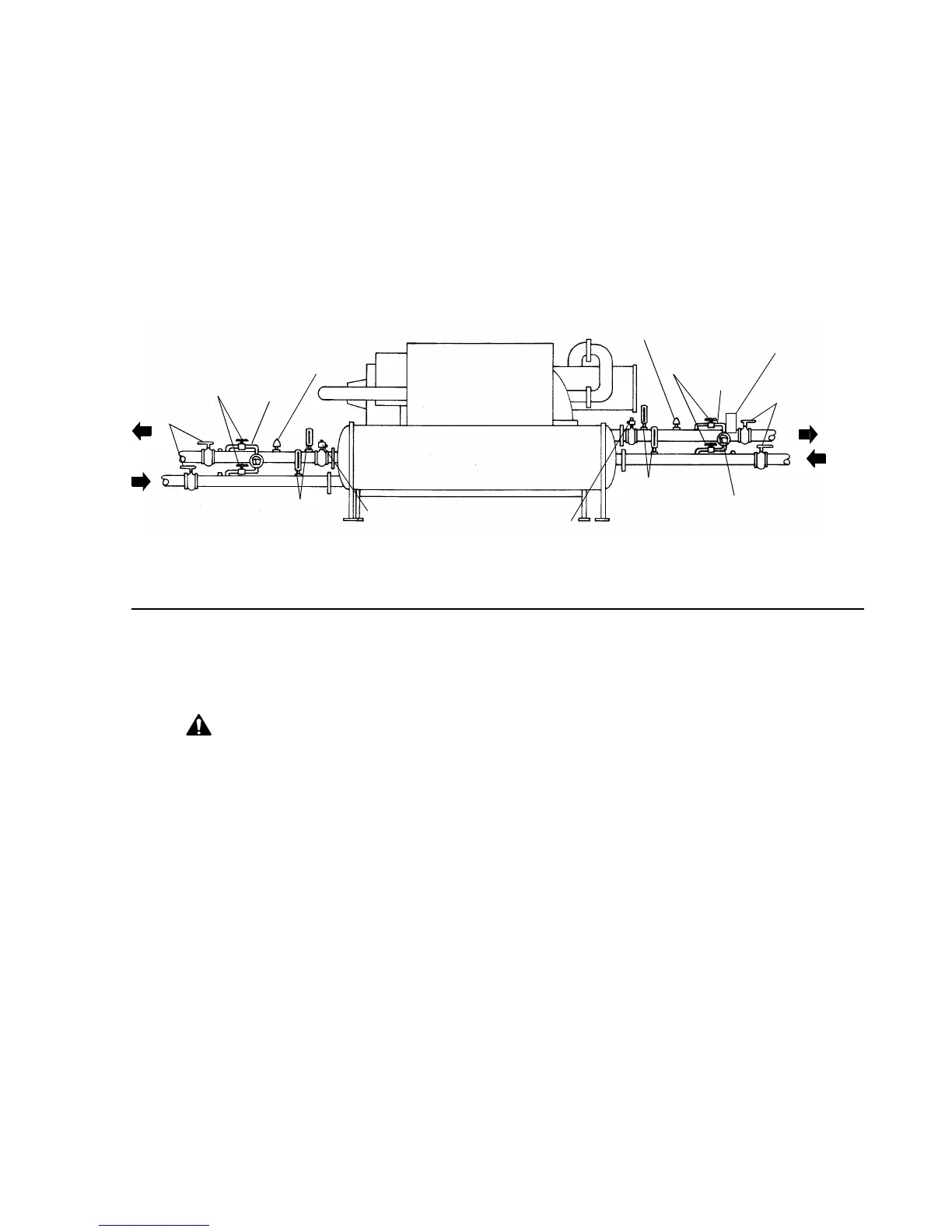

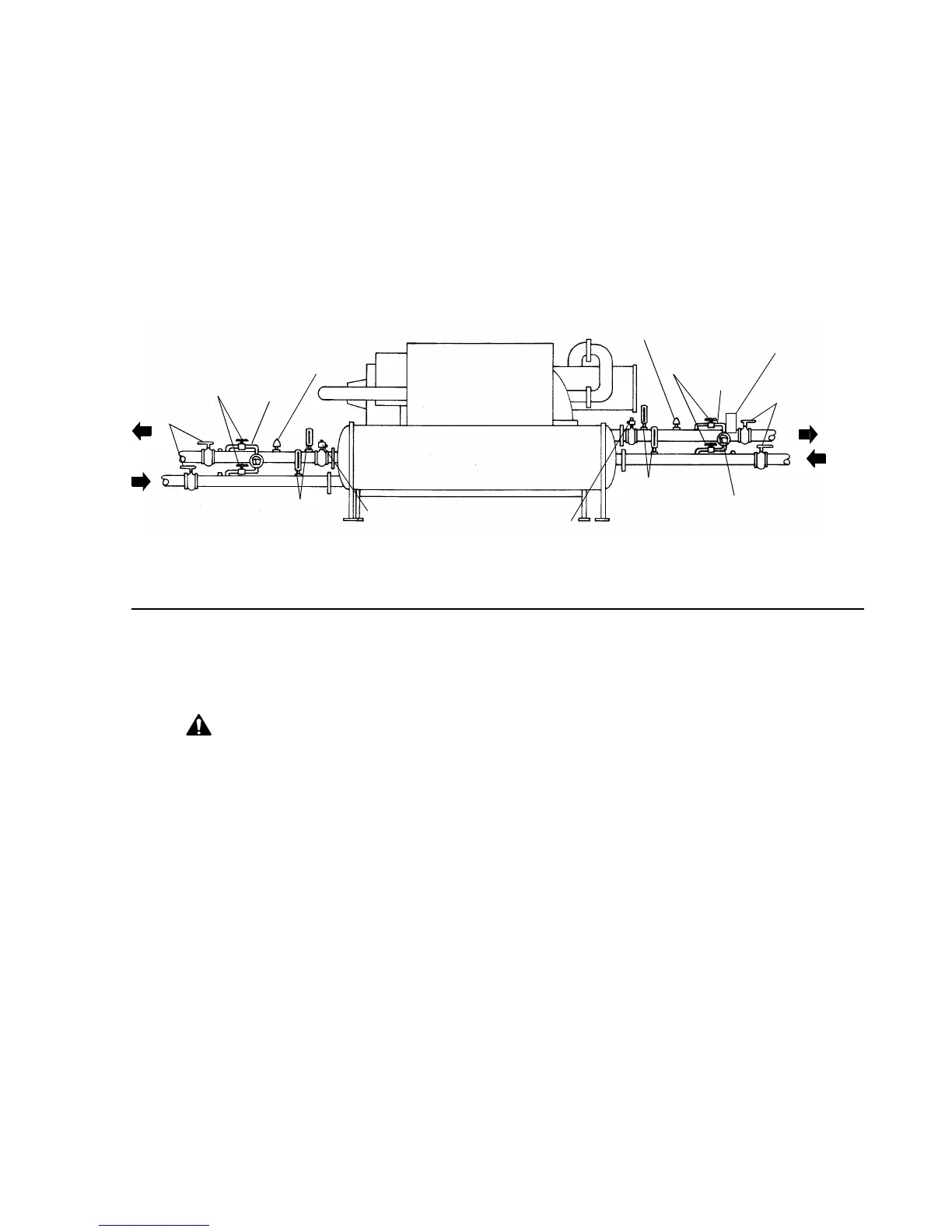

Install field-supplied thermometers and pressure

gauges (with manifolds, whenever practical) as

shown in

Figure 16

. Locate pressure gauges or taps

in a straight run of pipe; avoid placement near

elbows, etc. Be sure to install the gauges at the same

elevation on each shell if the shells have opposite-

end water connections.

To read manifolded water pressure gauges, open

one valve and close the other (depending upon the

reading desired). This eliminates errors resulting

from differently calibrated gauges installed at

unmatched elevations.

Figure 16

Typical Thermometer, Valving, and Manifold Pressure Gauge Set-up

Water Pressure Relief Valves

CAUTION

CAUTION: Install a pressure relief

valve in both evaporator and con-

denser water systems. Failure to do

so could result in shell damage.

Install a water pressure relief valve in one of the

condenser and one of the evaporator water box drain

connections or on the shell side of any shutoff valve.

Water vessels with close-coupled shutoff valves have

a high potential for hydrostatic pressure buildup on a

water temperature increase. Refer to applicable

codes for relief valve installation guidelines.

Flow Sensing Devices

Use field-provided flow switches or differential

pressure switches with pump interlocks to sense

system water flow. Flow switch locations are

schematically shown in

Figure 16

.

To provide chiller protection, install and wire flow

switches in series with the water pump interlocks, for

both chilled water and condenser water circuits (refer

to the Installation Electrical section). Specific

connections and schematic wiring diagrams are

shipped with the unit.

Flow switches must stop or prevent compressor

operation if either system water flow drops off below

the required minimum shown on the pressure drop

curves. Follow the manufacturer’s recommendations

for selection and installation procedures. General

guidelines for flow switch installation are outlined

below.

q Mount the switch upright, with a minimum of 5

pipe diameters straight, horizontal run on each

side.

q Do not install close to elbows, orifices or valves.

NOTE: The arrow on the switch must point in the

direction of the water flow.

q To prevent switch fluttering, remove all air from

the water system

Pressure Differential

Gauge

Pressure Differential

Gauge

Isolation

Valves

Isolation

Valves

Manifold

Manifold

Flow Switch

Flow Switch

Shutoff

Valves

Shutoff

Valves

Thermometers

Thermometers

Relief

Valve

Relief

Valve

Cond

Evap

Water

Flow

Water

Flow

Cond Water

Reg. Valve (Opt.)

NOTE: Refer to Trane Engineering Bulletin RLC-EB-3 for sound-sensitive applications.

Loading...

Loading...