2 - 6 RTHC-IOM-1C

Do not use the threaded holes in

the compressor to lift or assist in

lifting the unit. They are not

intended for that purpose and

could create a dangerous situa-

tion.

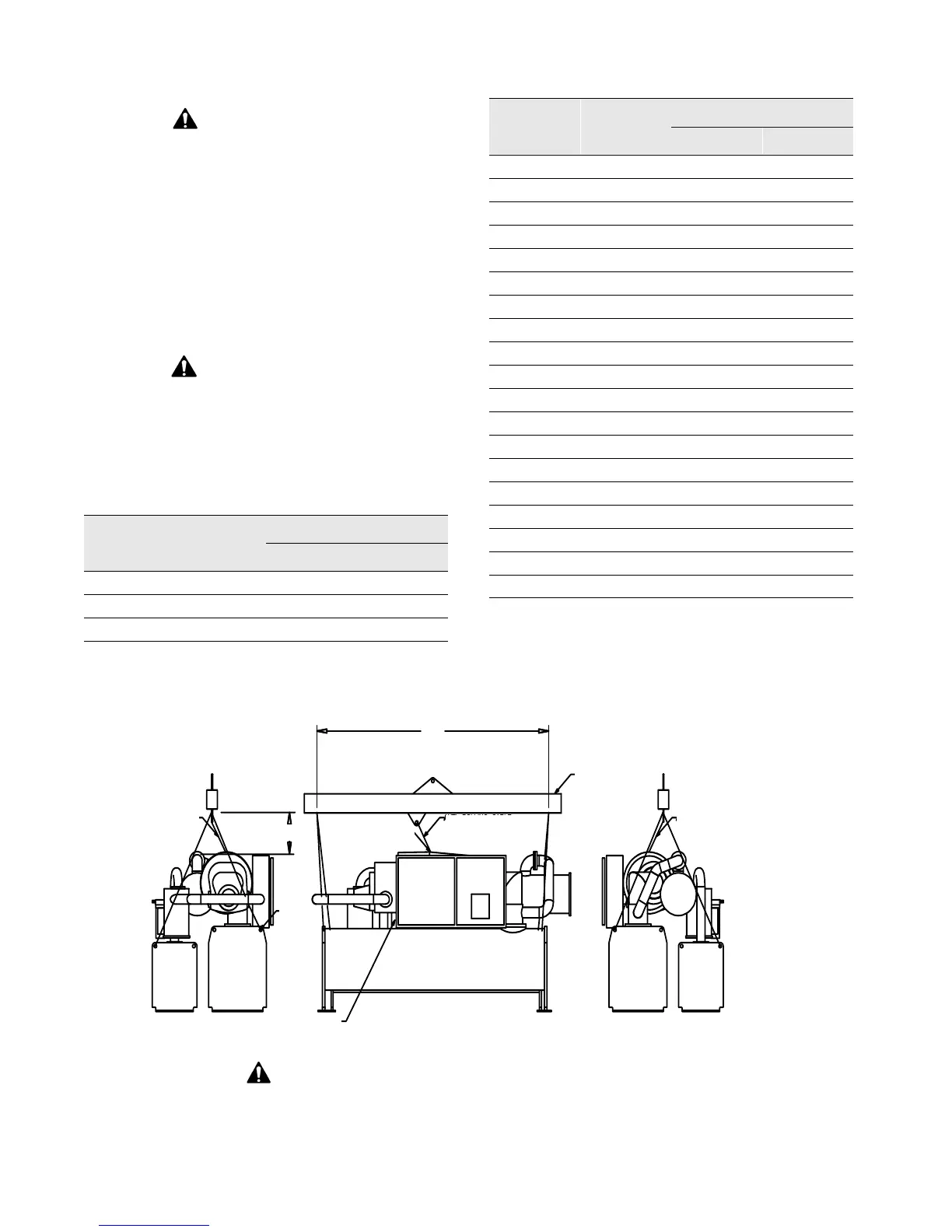

3 Install clevis connectors in lifting holes provided

on the unit. Attach lifting chains or cables to clevis

connectors as shown in

Figure 6

. Each cable

alone must be strong enough to lift the chiller.

CAUTION: Lifting Beam Location!

Always position the lifting beam so

that cables do not contact the unit.

Failure to do so may result in unit

damage.

Table 10

Weights and Rigging (Use with Figure 6 )

*

Designator corresponds to digits 6, 7, 12, 13, 16, 17 of model

number

Figure 6

Lifting the Unit

Unit Model

Number

*

Lifting

Weight (lb)

Dimension (ft) (Fig. 6)

A B

E3G3G3

20400 12 11

E3F2F3

17700 12 11

E3D2E2

15300 10 9

D3G3G3

20100 12 11

D3F2F3

17400 12 11

D3D2E2

15000 10 9

D2G3G3

20100 12 11

D2F2F3

17400 12 11

D2D2E2

15000 10 9

D1G2G2

19600 12 11

D1F1F2

16700 12 11

D1D1E1

15000 10 9

C2G1G1

18500 12 11

C2D3E3

14600 10 9

C2B3C2

13500 10 9

C1E1F1

15600 12 11

C1B3C2

13600 10 9

C1B2C1

13300 10 9

B2C2D2

10500 12 11

B2B2B2

9800 10 9

B1C1D1

10300 12 11

B1B1B1

9700 10 9

Unit Model

Number

*

Lifting

Weight (lb)

Dimension (ft) (Fig. 6)

A B

WARNING

To prevent personal injury or equipment damage, refer to Trane RTHC-SB-2

for units that must be disassembled due to limited access.

Lifting Cable

positioned

inside

discharge pipe -

No Contact

Attach

Eyebolt

to one

of three compressor

housing mounting holes

Note: Refer to specific unit

submittals or Figure 5 for

weight distribution

Evap

Cond

location

Unit Model Number

holes

Lifting

Starter

Controls

Cable

Anti-rolling

Anti-rolling

Cable

A Beam

Eyelet

Cable

Anti-rolling

B

24”

Loading...

Loading...