Installation, Operation and Maintenance 2 - 27

.

* Only used with isolation valve option

Thermal Insulation

All RTHC units are available with optional factory

installed thermal insulation. If the unit is not factory

insulated, install insulation over the areas shaded in

Figure 18

. Refer to

Table 13

for types and quantities

of insulation required.

NOTES: Liquid line filter, refrigerant charging valves,

water temperature sensors, drain and vent

connections when insulated must remain accessible

for service.

Use only water-base latex paint on factory-applied

insulation. Failure to do so may result in insulation

shrinkage.

More (thicker insulation may be required in areas

with high humidity.

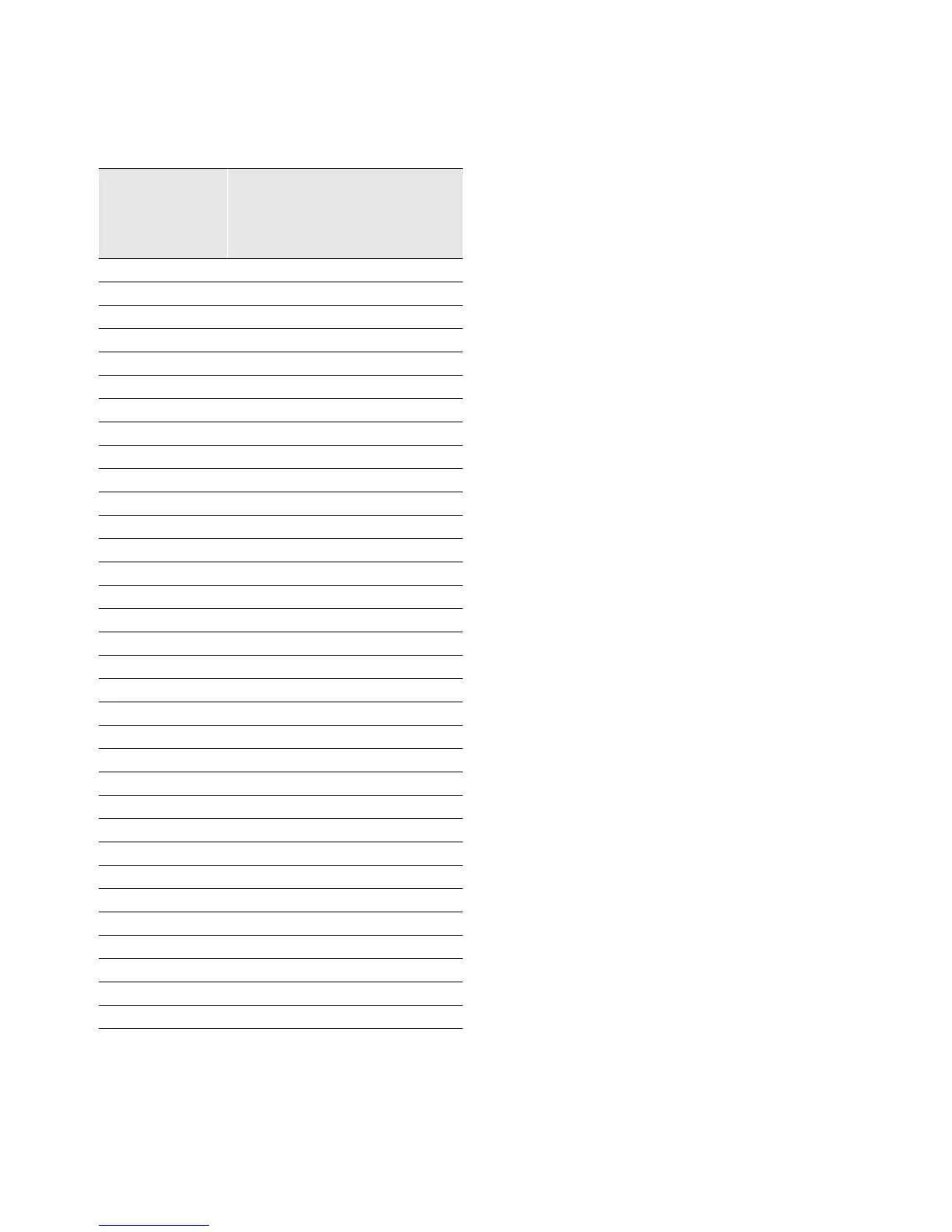

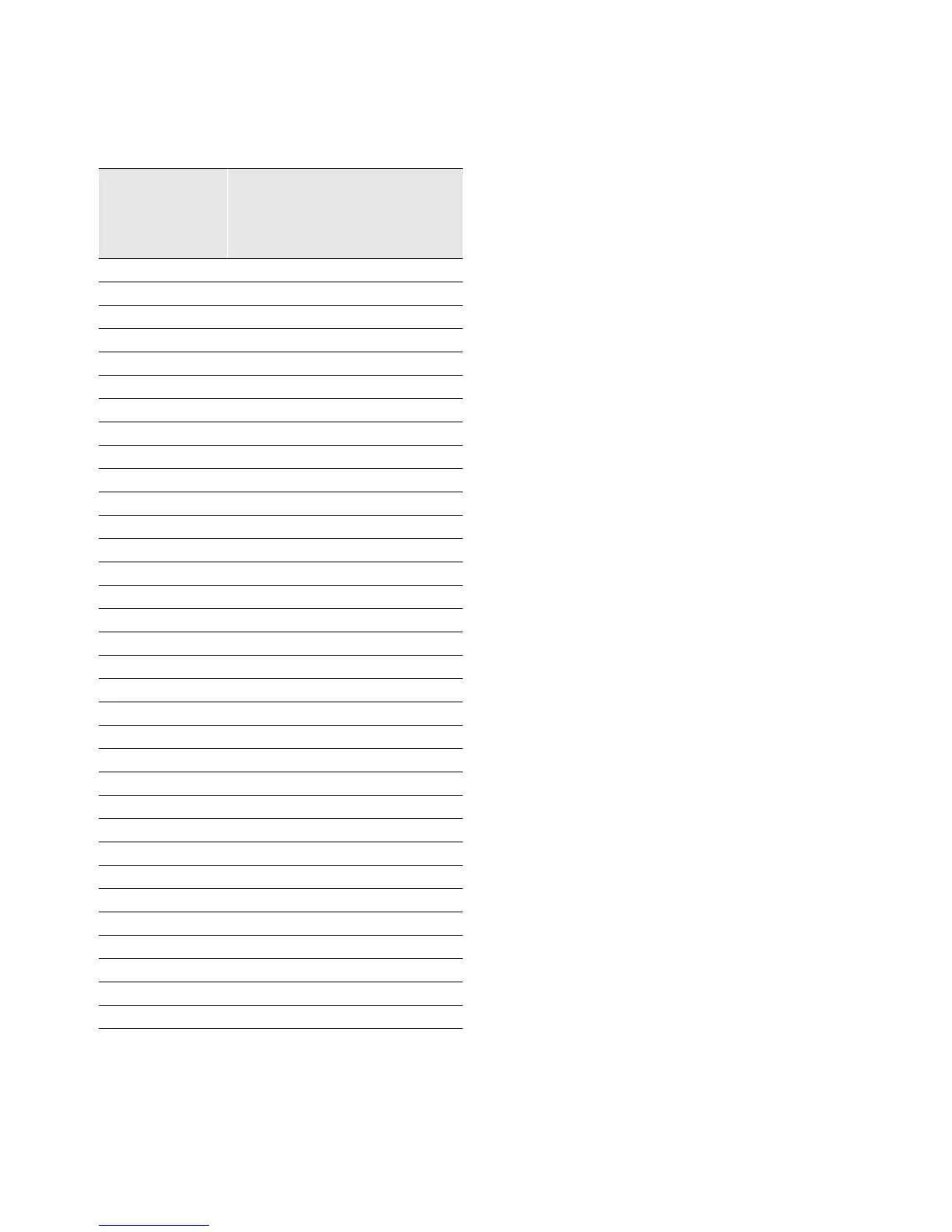

Table 12

Pressure Relief Valve Data

Valve Location

Number of

Valves

Rated

Capacity

per Relief

Valve

(lba/min)

Pipe Size

(in NPT)

Evap - B1

1 43.5 1

Evap - B2

1 43.5 1

Evap -B3

1 43.5 1

Evap -C1

1 43.5 1

Evap - C2

1 43.5 1

Evap - D1

1 43.5 1

Evap - D2

1 43.5 1

Evap - D3

1 43.5 1

Evap - F1

1 43.5 1

Evap - F2

1 43.5 1

Evap - E1

1 43.5 1

Evap - G1

1 76.2 1-1/4

Evap - G2

1 76.2 1-1/4

Evap - G3

1 76.2 1-1/4

Cond - B1

1 43.5 1

Cond - B2

1 43.5 1

Evap - C1

1 43.5 1

Evap - C2

1 43.5 1

Cond - D1

1 43.5 1

Cond - D2

1 43.5 1

Cond - E1

2 43.5 1

Cond - E2

2 43.5 1

Cond - E3

1 43.5 1

Cond - F1

1 43.5 1

Cond - F2

2 43.5 1

Cond - F3

2 43.5 1

Cond - G1

1 43.5 1

Cond - G2

2 43.5 1

Cond - G3

2 43.5 1

Comp - B1/B2*

2 76.2 1-1/4

Comp - C1/C2*

3 76.2 1-1/4

Comp - D1/D2/D3*

3 76.2 1-1/4

Comp -E3

3 76.2 1-1/4

Loading...

Loading...