Installation, Operation and Maintenance 5 - 25

chiller with a solid state starter option, only the EA

series type starter applies. See section 3 for an

overview of the solid state starter and its settings.

Startup Contactor Test - Y-D Starters Only

This screen shall be displayed only when the starter

type is Y-Delta, otherwise this screen is skipped.

where disabled is the ROM default.

Rated Load Amps

This value should be set at the design rated load

amps as determined during the initial selection

process. If conditions change, contact Trane

Technical Support for new settings based on the new

operating conditions.

The range of values is 0-2500 in 1 amp increments.

The ROM default is 300 amps.

Motor Heating Constant

The range of values XXX is 0 to 100 minutes in 1

minute increments. The ROM default is 5 minutes.

This value is used in the calculation of the restart

inhibit timer. Refer to the following table for proper

settings based on compressor size.

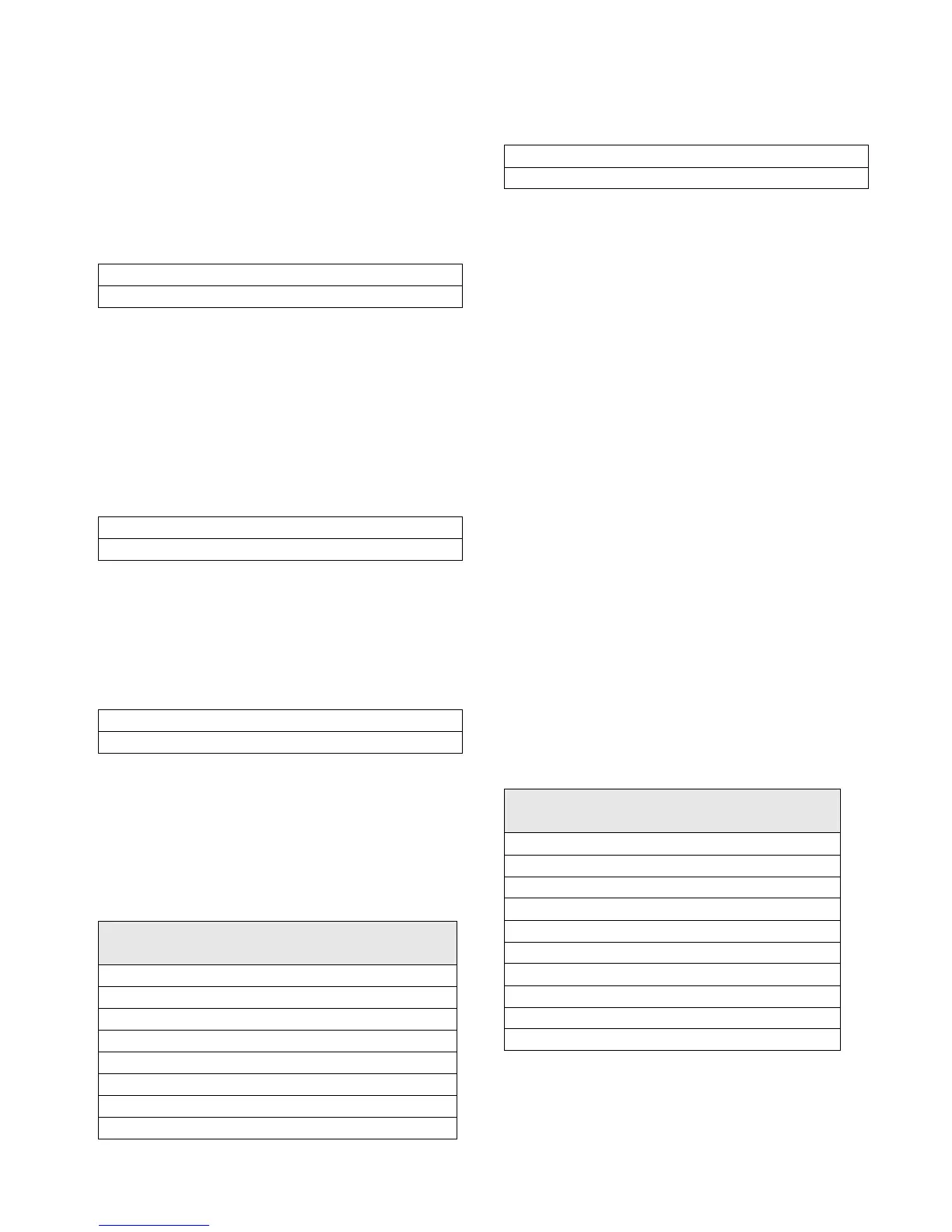

Table 17

Recommended Motor Heating Constant Settings

Current Overload Setting #1

The range of values is decimal 00 through 31. The

ROM default is 00. Both the maximum acceleration

timers and the overload settings are not adjustable

from either the remote CLD or Tracer or any other

remote/external device.

The UCP2 will continuously monitor compressor

current to provide running overcurrent and locked

rotor protection. Overcurrent protection is based on

the phase with the highest current. It will trigger a

manually resettable diagnostic, shutting the unit

down, when the current exceeds a specified time-trip

curve.

The compressor overload is based on the unit RLA.

RLA is set in the UCP2 menu items along with the

current overload settings specific to a certain current

transformer (CT) and machine nameplate RLA. Use

the following procedure to set the current overload #1

and #2.

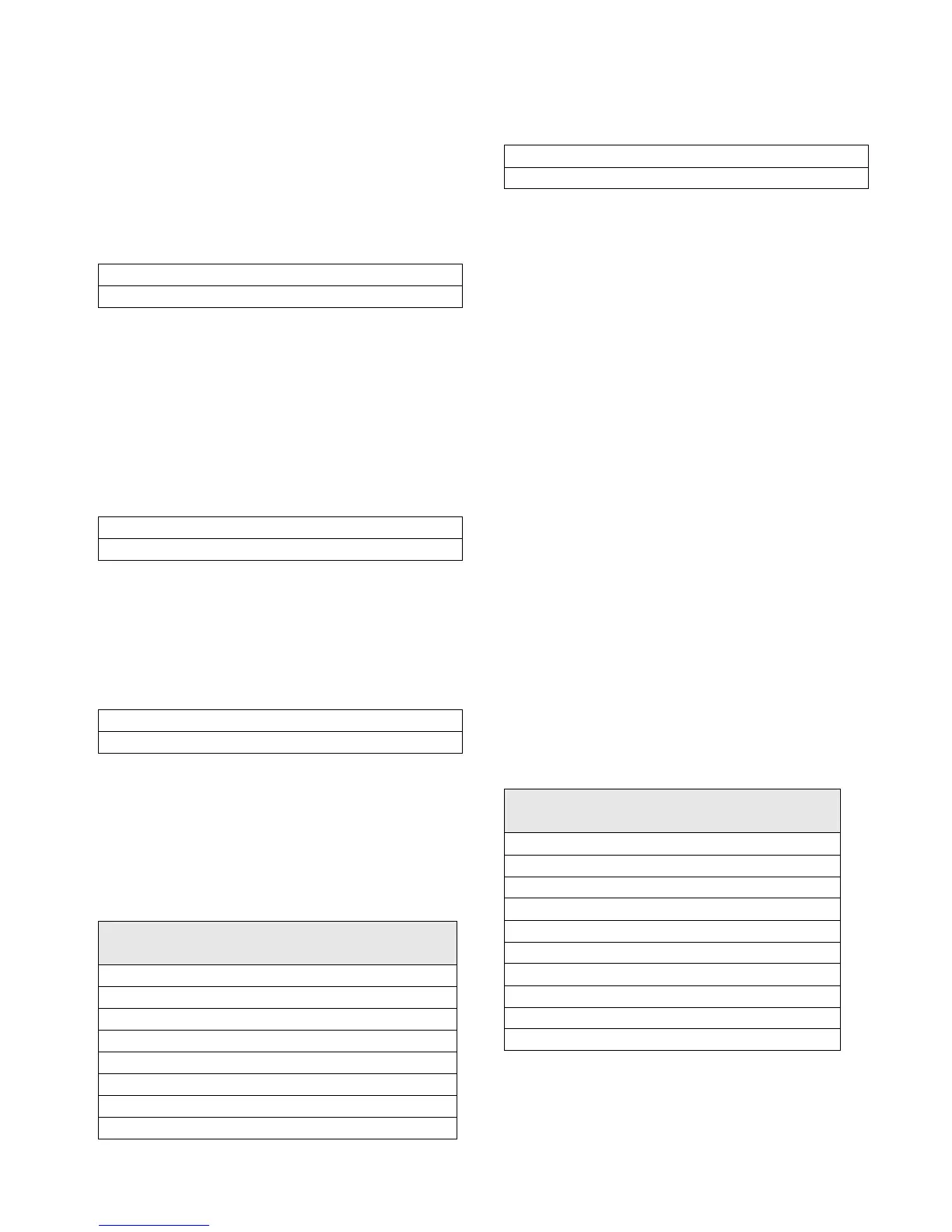

First determine the CT Factor where

CT Factor = Unit Nameplate RLA/ CT Rating x 100%

Look up the CT rating from the table below. The CT

Factor must be 66% or greater, but no more that

100% of the Nameplate RLA. Where more than one

selection is possible, use the CT rating that will give

the lowest CT Factor.

From the calculated CT Factor, the Motor Current

Overload Settings # 1 and #2 can be found in

Table

18

following. Note that when one setting is changed,

Level 2 Contactor Integrity Test: [d/e]

Press (+)(-) to Change Setting

Rated Load Amps: xxxx Amps

Press (+)(-) to Change Setting

Motor Heating Constant: xxx min

Press (+)(-) to Change Setting

Compressor

Motor Heating Constant

(minutes)

B1 3

B2 3

C1 4

C2 4

D1 5

D2 5

D3 5

E3 5

Current Overload Setting #1: xxx

Press (+)(-) to Change Setting

Unit Nameplate

RLA

Extension

(X13580269-)

CT Rating Amp

33-50 -09 50

50-75 -10 75

67-100 -01 100

100-150 -02 150

134-200 -03 200

184-275 -04 275

267-400 -05 400

334-500 -06 500

467-700 -07 700

667-1000 -08 1000

Loading...

Loading...