20 | IM-112 DECEMBER 2019

Vertical Turbine Pumps

2001299 - VTP- IOM

20 | IM-112 DECEMBER 2019

Vertical Turbine Pumps

2001299 - VTP- IOM

20 | IM-112 DECEMBER 2019

Vertical Turbine Pumps

2001299 - VTP- IOM

Vertical Turbine Pumps

Installation

Document Name: 2001299-VTP-IOM-EN Page 20 of 67

Revision 3 Copyright © 2014, Weir Floway, Inc. All Rights Reserved. Issue Date: December 12, 2014

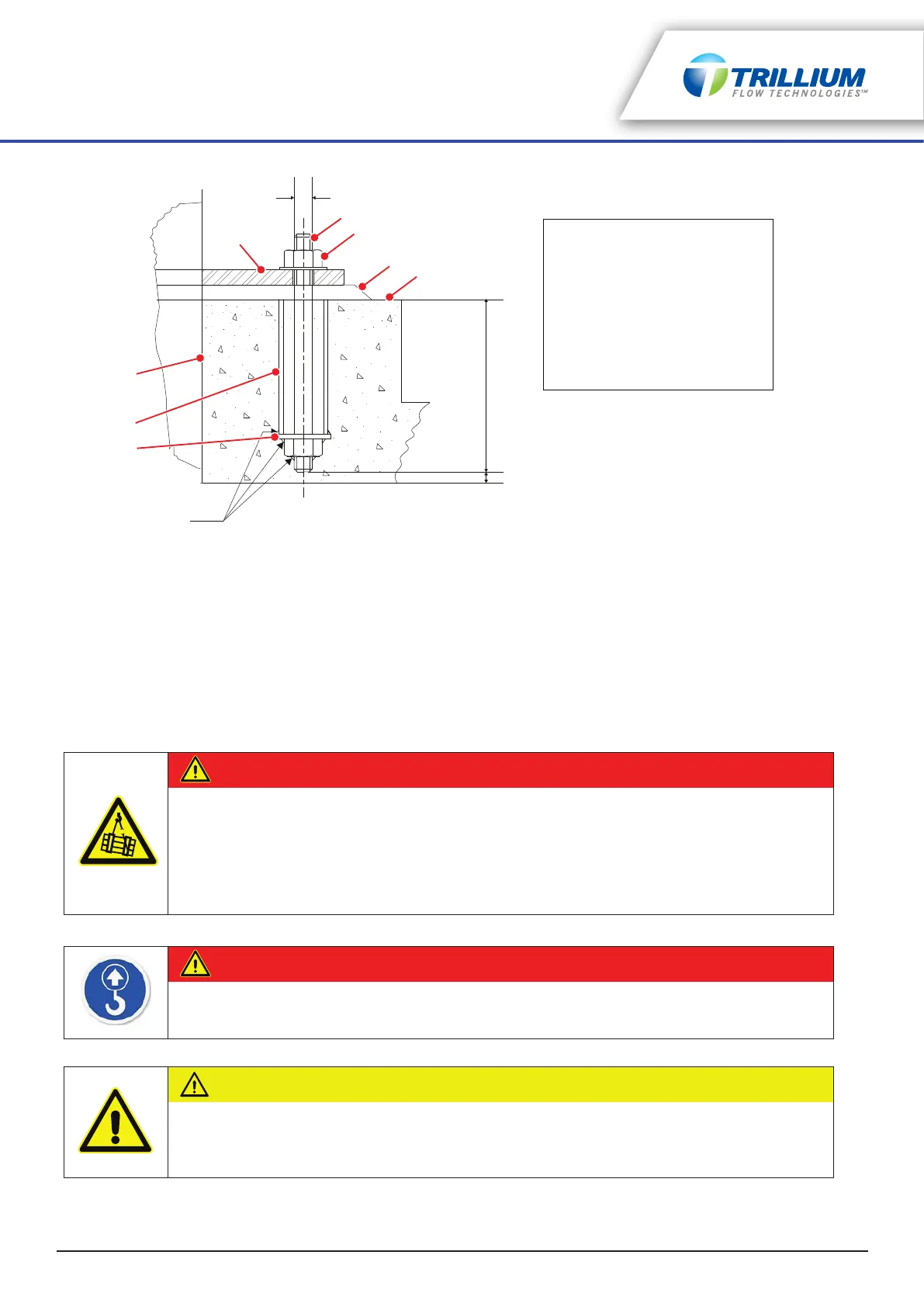

Figure 5-1: Recommended Anchor Bolt Arrangement

5.3 Suction Barrel Installation

If a suction barrel has been furnished with the pump it must be mounted to a firm foundation. The suction

vessel must provide permanent, rigid support to the pump and motor. It is recommended that concrete

foundations have anchor bolts installed in sleeves twice the diameter of the bolt to allow alignment with the

holes in the mounting plate, however, sleeves are not required and anchor bolts may be directly installed in

concrete. Level the pump mounting surface, then grout and anchor in place.

5.4 Vertical Turbine Pump Installation for Wet Pit (Type VS1)

1. Position the lifting equipment so it will center over the foundation opening.

2. If a soleplate is used, level the mounting surface then grout and anchor in place.

DANGER

LIFTING DEVICE SAFETY

• Use mechanical lifting devices to lift heavy or awkward components.

• Lifting devices must be in good condition, certified, and tagged.

• Lifting devices of adequate capacity must be used whenever they are required.

• Personnel must never work under suspended loads.

DANGER

LIFTING POINT SAFETY

Check lifting lugs are in suitable condition for lifting, before lifting pump parts.

CAUTION

DAMAGE TO THE PUMP

Clean the sump and piping of all abrasive particles and loose debris before starting

installation, to avoid any damage to the pump.

7

1/4" fillet welds

(all around)

"D"

2

3

10 x "D"

1 1/2" min

4

1

8

1. Anchor Bolt (diameter “D”)

2. Nut

3. Grout

4. Floor

5. 4 x "D" Square Plate

6. 2 x "D" Sleeve Diameter

7. Opening for Pump

8. Mounting Plate (sole plate,

discharge head, or barrel plate)

Loading...

Loading...