31 | IM-112 DECEMBER 2019

Vertical Turbine Pumps

2001299 - VTP- IOM

31 | IM-112 DECEMBER 2019

Vertical Turbine Pumps

2001299 - VTP- IOM

31 | IM-112 DECEMBER 2019

Vertical Turbine Pumps

2001299 - VTP- IOM

Vertical Turbine Pumps

Installation

Document Name: 2001299-VTP-IOM-EN Page 31 of 67

Revision 3 Copyright © 2014, Weir Floway, Inc. All Rights Reserved. Issue Date: December 12, 2014

• Use the highest discharge head that the unit is expected to operate against to calculate the impeller

adjustment value.

• For example: a pump designed to operate at 400 feet discharge head but will also be operated

against a closed valve for short intervals at which time it will produce 500 feet of pump pressure,

therefore 5 x 0.005

= 0.025. For a unit with 20 feet of column assembly, the calculation would be:

2 x 0.005 = 0.010". The initial adjustment would be 0.025

+ 0.010 + 0.015 = 0.050.

Refer to Table 5-1 to determine how many turns or fraction of a turn is necessary for the shaft diameter

supplied. For example: a 1 11/16 - 10

TPI shaft will provide 0.100 adjustment per turn of nut. Therefore

1/2 turn of the nut will provide the required 0.050

impeller setting in the previous example.

5.9 Impeller Adjustment - Hollow Shaft Driver

Impeller adjustment when using hollow shaft driver is accomplished at the top of the driver by the following

procedure.

1. Remove the driver canopy.

2. Install the headshaft as outlined in “Hollow Shaft Driver Installation” on page 24 if not already in place.

3. Install the driver clutch as per the driver instruction manual and bolt into place.

4. Install the gib key, ensuring the top of the gib key pushes down below the top of the clutch. To prevent

interference with the headshaft nut, fit the gib key to both the motor clutch and the headshaft. The key

must slide in smoothly in the keyway.

5. Check the shaft position; the impellers must be fully seated against the bowls prior to adjusting the

impellers.

6. Thread the headshaft nut down (right hand threads) until the impellers are lifted off their seat and the

shaft rotates freely. When semi-open impellers are used, the correct determination of the point where

the impellers just barely clear their seat is very important for proper adjustment.

7. Adjust the impellers as outlined in “Impeller Adjustment - General” on page 29.

8. Lock the headshaft nut with the lockscrew inserted down through the holes in the headshaft nut and

threaded into the driver clutch.

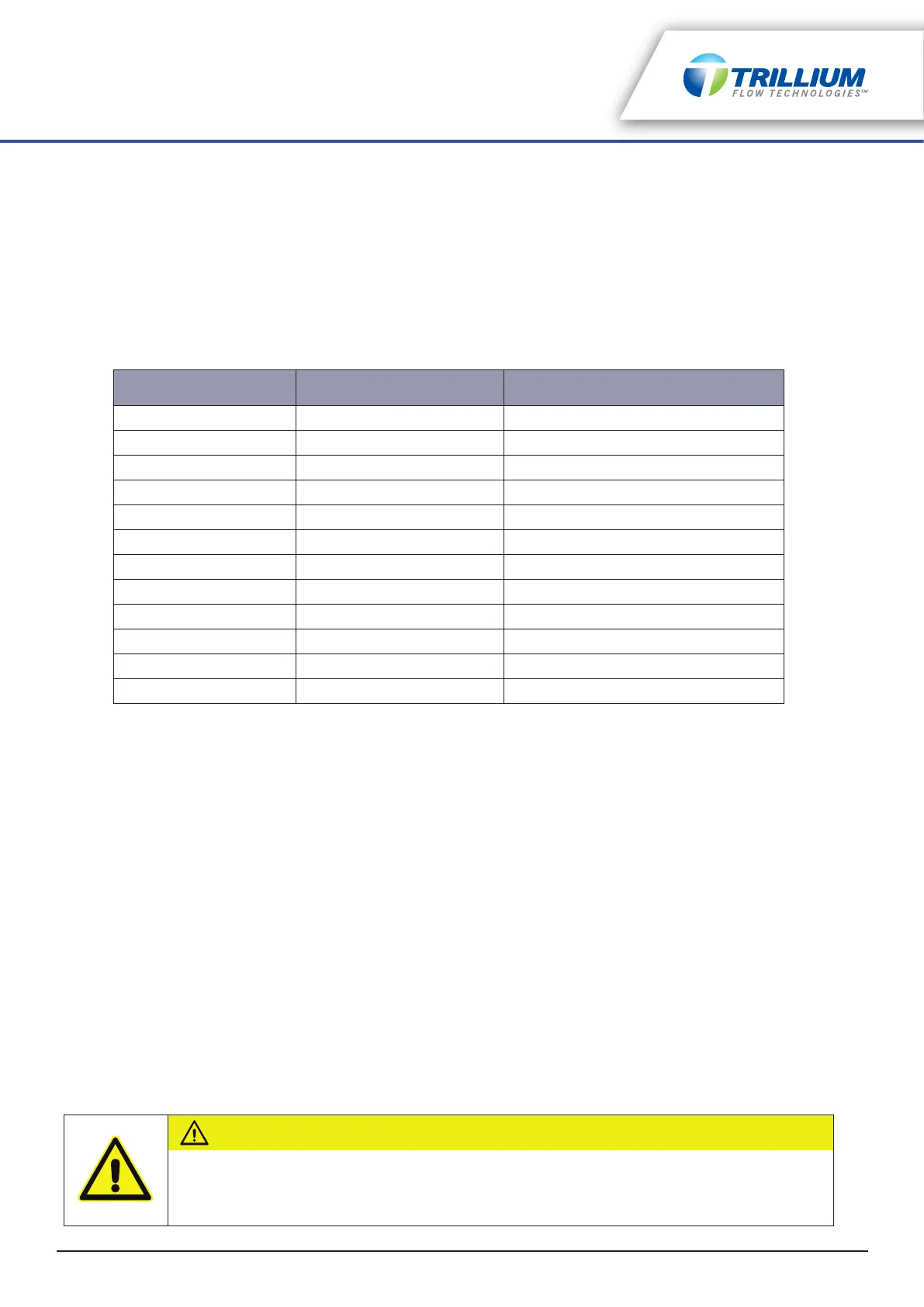

Shaft Diameter Headshaft Nut (thread/inch) Inches per Full Turn of Adjusting Nut

3/4

16 TPI - R.H. 0.063

1

14 TPI - R.H. 0.071

1 1/4

12 TPI - R.H. 0.083

1 1/2

12 TPI - R.H. 0.083

1 11/16

10 TPI - R.H. 0.100

1 15/16

12 TPI - R.H. 0.083

2 1/4

12 TPI - R.H. 0.083

2 7/16

12 TPI - R.H. 0.083

2 11/16

12 TPI - R.H. 0.083

2 15/16

10 TPI - R.H. 0.100

3 3/16

8 TPI - R.H. 0.125

3 7/16

8 TPI - R.H. 0.125

Table 5-1: Shaft Diameter Turns

CAUTION

DAMAGE TO THE PUMP AND THE DRIVER

Always ensure the headshaft nut is locked before starting the driver to avoid damage to the

pump and the driver.

Loading...

Loading...