55 | IM-112 DECEMBER 2019

Vertical Turbine Pumps

2001299 - VTP- IOM

55 | IM-112 DECEMBER 2019

Vertical Turbine Pumps

2001299 - VTP- IOM

55 | IM-112 DECEMBER 2019

Vertical Turbine Pumps

2001299 - VTP- IOM

Vertical Turbine Pumps

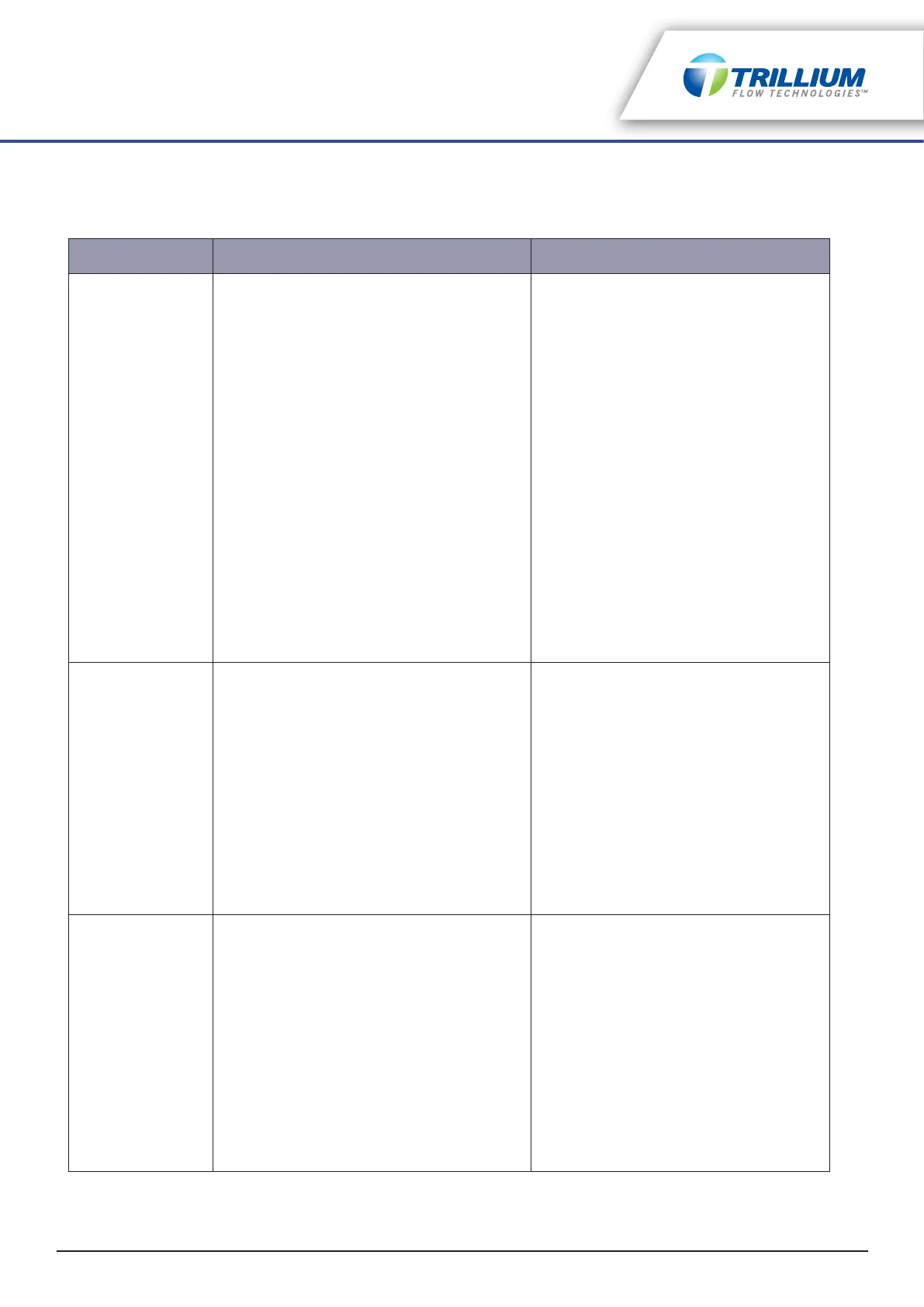

Troubleshooting

Document Name: 2001299-VTP-IOM-EN Page 55 of 67

Revision 3 Copyright © 2014, Weir Floway, Inc. All Rights Reserved. Issue Date: December 12, 2014

10 Troubleshooting

Refer to Table 10-1 for troubleshooting instructions.

Condition Probable Cause Remedy

Pump not running. 1 Motor overload protection contacts open.

a Incorrect control box.

b Incorrect connections.

c Faulty overloads.

d Low Voltage.

e Ambient temperature of control box or

starter too high.

6 Blown fuse, broken or loose electric

connections.

7 Defective Motor.

8 Faulty control equipment.

9 Faulty switch.

10Pump binding.

1 Do the following:

a Check nameplate for HP and

voltage.

b Check wiring diagram furnished with

starter.

c Replace.

d Check voltage at pump side of

control box.

e Use ambient compensated relays.

6 Check fuses, relays or heater elements

for correct size and all electrical

connection.

7 Repair or replace.

8 Check all circuits and repair.

9 Repair or replace.

10Pull master switch, rotate pump by hand

to check. Check impeller adjustment or

disassemble the unit to determine the

cause.

Pump is running but

no fluid delivered.

1 Line check valve backward.

2 Line check valve stuck.

3 Unit running backwards.

4 Lift too high for pump.

5 Pump not submerged.

6 Excessive amounts of air or gas.

7 Intake strainer or impeller plugged, or pump

in mud or sand.

8 Impeller(s) loose on shaft.

1 Reverse check valve.

2 Free the valve.

3 Refer to

“Hollow Shaft Driver Installation”

on page 24, step 12.

4 Check with performance curve.

5 Lower pump if possible or add fluid to

system.

6 Correct conditions.

7 Start & stop pump several times or use

line pressure if available to back flush.

Pull pump and clean.

8 Pull unit and repair.

Reduced capacity. 1 Bypass open.

2 Lift too high for pump.

3 Motor not coming up to speed.

4 Strainer or impellers partly plugged.

5 Scaled or corroded discharge pipe or leaks

anywhere in system.

6 Excessive amounts of air or gas.

7 Excess wear due to abrasives.

8 Impellers not properly adjusted.

9 Impeller(s) loose on shaft.

1 Check bypass valving.

2 Check performance curve.

3 Check voltage while unit is running.

4 Start & stop pump several times or use

line pressure if available to back flush.

Pull pump and clean.

5 Replace pipe or repair leaks.

6 Suitable conditions.

7 Replace worn parts.

8 Refer to

“Impeller Adjustment - General”

on page 29.

9 Pull the unit and repair.

Table 10-1: Troubleshooting Chart

Loading...

Loading...