Vertical Turbine Pumps

Installation

Document Name: 2001299-VTP-IOM-EN Page 26 of 67

Revision 3 Copyright © 2014, Weir Floway, Inc. All Rights Reserved. Issue Date: December 12, 2014

14. Clean all the shaft threads (on top shaft and both ends of headshaft). Try the lineshaft coupling and

headshaft nut on their respective threads. These must thread on by hand. If not, clean up the threads

with a fine three cornered file. Check the ends of the shaft where they butt inside the lineshaft coupling.

Ends must be square and clean. Fit the gib key to both motor clutch and headshaft. The key must slide

smoothly in both keyways.

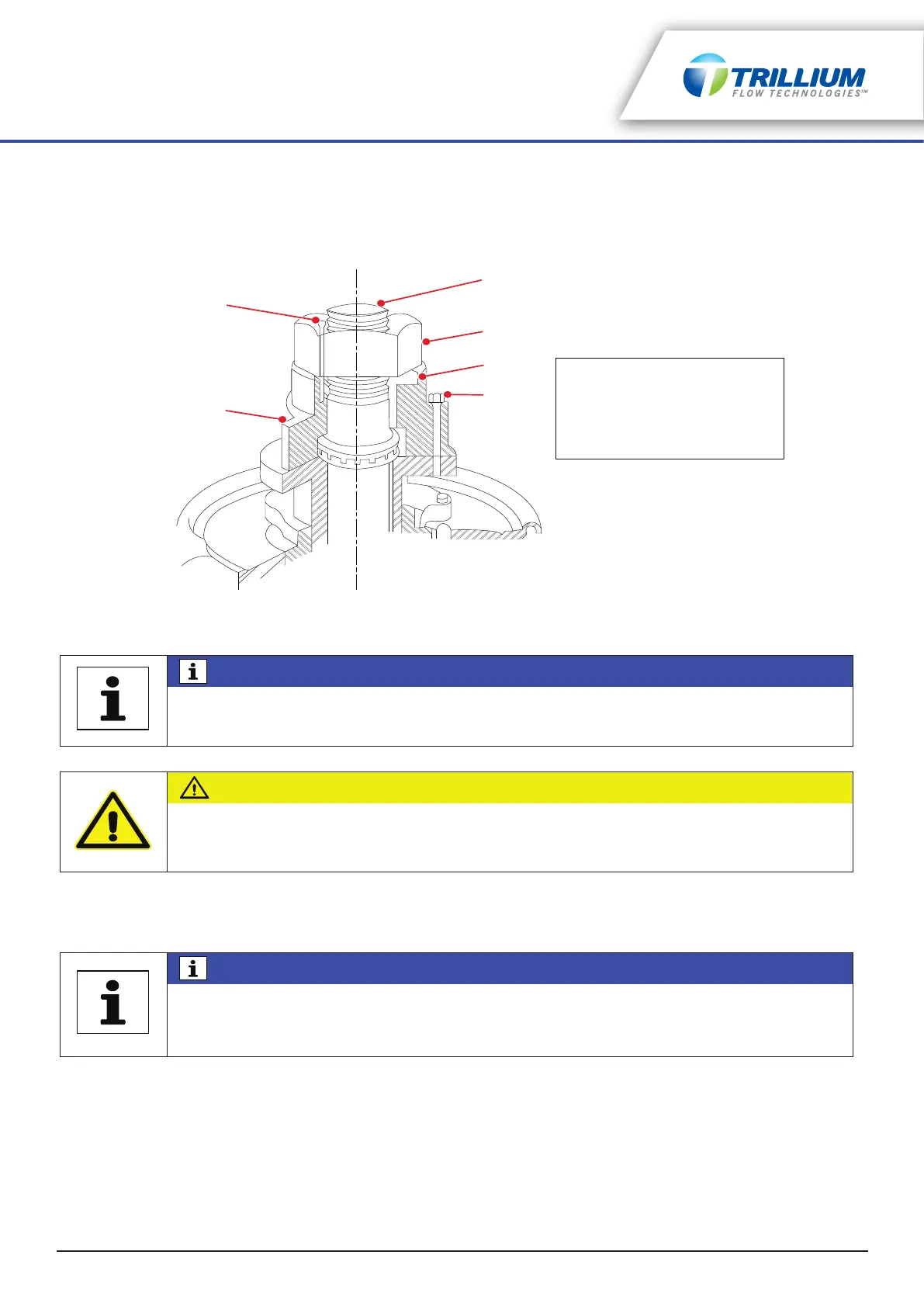

Figure 5-4: Hollow Shaft Driver Clutch

15. Lubricate the top shaft threads and thread (left hand threads) the lineshaft coupling half way onto the top

shaft.

16. Lubricate the headshaft threads and lower the headshaft carefully down through the driver, and thread

into the lineshaft coupling. Shafts must butt against each other.

17. Install the clutch on the driver and ensure that it fits down properly.

18. Install pre-fitted gib key in the clutch and the shaft.

19. Thread adjusting the nut down (right hand threads) on the shaft until it bears against the clutch.

20. Refer to “Impeller Adjustment - General” on page 29 for impeller adjustment.

21. Adjust mechanical seal after adjusting impellers.

NOTICE

For units equipped with one piece headshaft (no lineshaft coupling between driver and

pump) steps 15 and 16 will not be applicable.

CAUTION

EQUIPMENT DAMAGE

Apply thread lubricant only to male shaft threads sparingly to avoid buildup between ends

of shaft which can cause misalignment.

NOTICE

Headshaft must stand centered (long shafts may lean slightly from own weight; however,

they can be centered without effort) in the driver hollow shaft. If not, check the driver

mounting flange for improper mounting and re-clean the shaft ends coupled inside the

discharge head.

Loading...

Loading...